Silicone-modified silicate coating and preparation method thereof

A silicate and silicone technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of poor film adhesion, poor water resistance, and poor leveling, and achieve good weather resistance, Excellent stain resistance and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

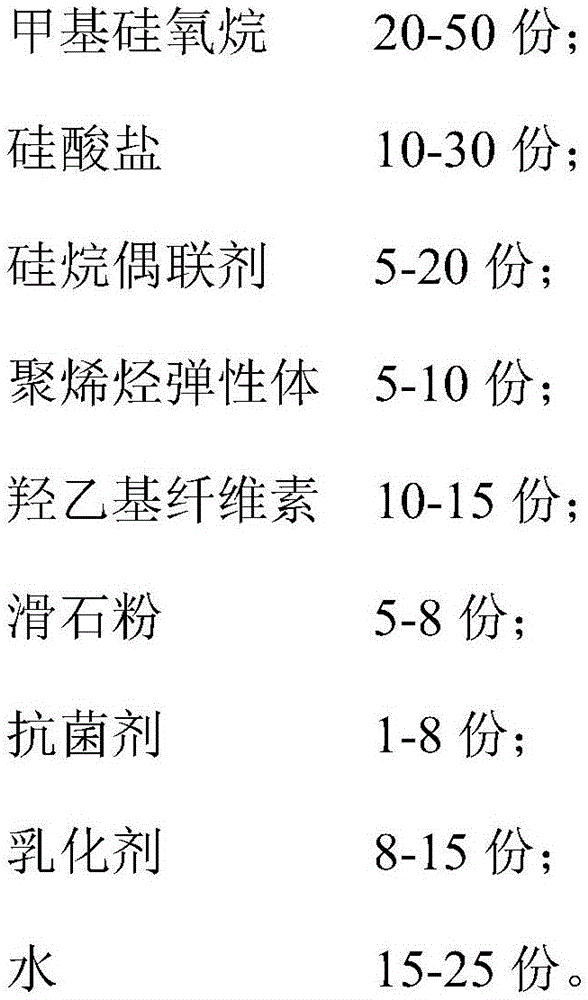

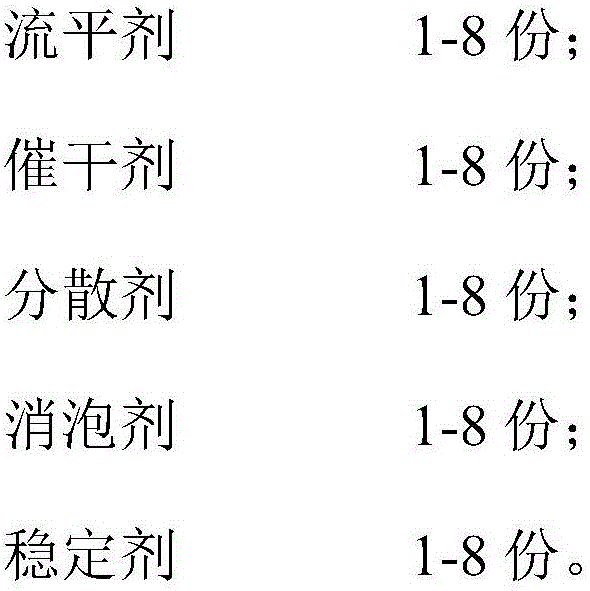

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of an organosilicon-modified silicate paint, comprising the following steps:

[0036] 1) Add the formulated amount of water into the container, then add the formulated amount of silicate, and stir for 5-15 minutes to obtain an aqueous silicate solution;

[0037] 2) Under the condition that the stirring speed is 250-600r / min, add the formula amount of methyl siloxane, silane coupling agent, polyolefin elastomer and emulsifier into the silicate aqueous solution, after the addition is completed, Adjust the speed to 100-120r / min, and keep it for 5-15min to get a semi-finished product;

[0038] 3) Add hydroxyethyl cellulose, talcum powder, antibacterial agent, leveling agent, drier, dispersant, defoamer and stabilizer into the semi-finished product and stir evenly to obtain the silicone Modified silicate coatings.

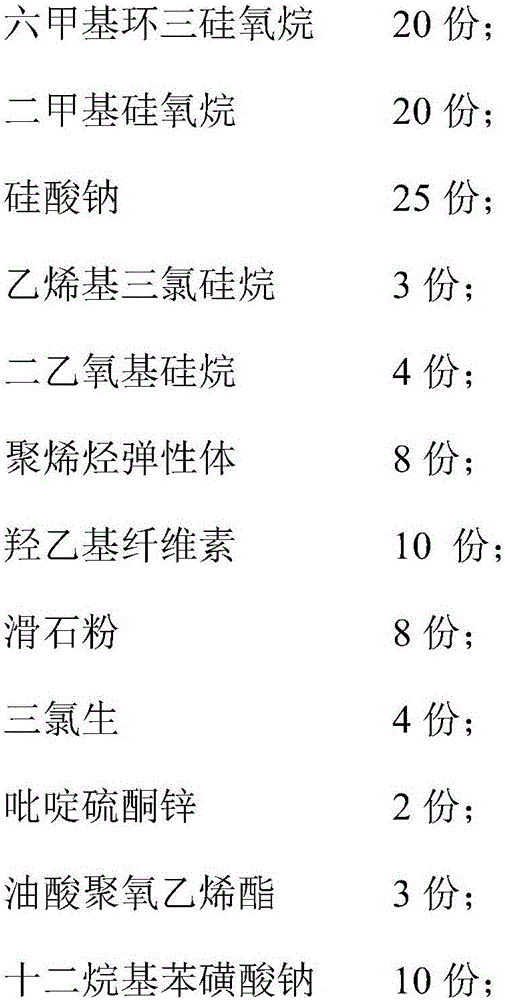

Embodiment 1

[0040] An organosilicon-modified silicate paint, comprising the following components in parts by weight (see Table 1 for details). The preparation process is as follows in sequence: 1) Add the formula amount of water into the container, then add the formula amount of silicate, and stir for 10 minutes to obtain the silicate aqueous solution; 2) Under the condition of stirring speed of 300r / min, the formula A certain amount of methyl siloxane, silane coupling agent, polyolefin elastomer and emulsifier are added in the silicate aqueous solution, after the addition is completed, the speed is adjusted to 110r / min, and kept for 10min to obtain a semi-finished product; 3) the Add hydroxyethyl cellulose, talcum powder, antibacterial agent, leveling agent, drier, dispersant, defoamer and stabilizer to the semi-finished product in the prescribed amount, and stir for 15 minutes to obtain the silicone-modified Silicate paint.

Embodiment 2

[0042] An organosilicon-modified silicate paint, comprising the following components in parts by weight (see Table 1 for details). The preparation process is as follows in sequence: 1) Add the formula amount of water into the container, then add the formula amount of silicate, and stir for 15 minutes to obtain the silicate aqueous solution; 2) Under the condition that the stirring speed is 600r / min, the formula A certain amount of methyl siloxane, silane coupling agent, polyolefin elastomer and emulsifier are added in the silicate aqueous solution. After the addition is completed, the speed is adjusted to 100r / min and kept for 5min to obtain a semi-finished product; 3) the Add hydroxyethyl cellulose, talcum powder, antibacterial agent, leveling agent, drier, dispersant, defoamer and stabilizer into the semi-finished product and stir for 25 minutes to obtain the silicone-modified Silicate paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com