Method for manufacturing metal laminated substrate for semiconductor element formation and metal laminated substrate for semiconductor element formation

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the roughness of the bonding interface, uneven deformation, and difficulty in stably manufacturing highly crystalline substrates, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

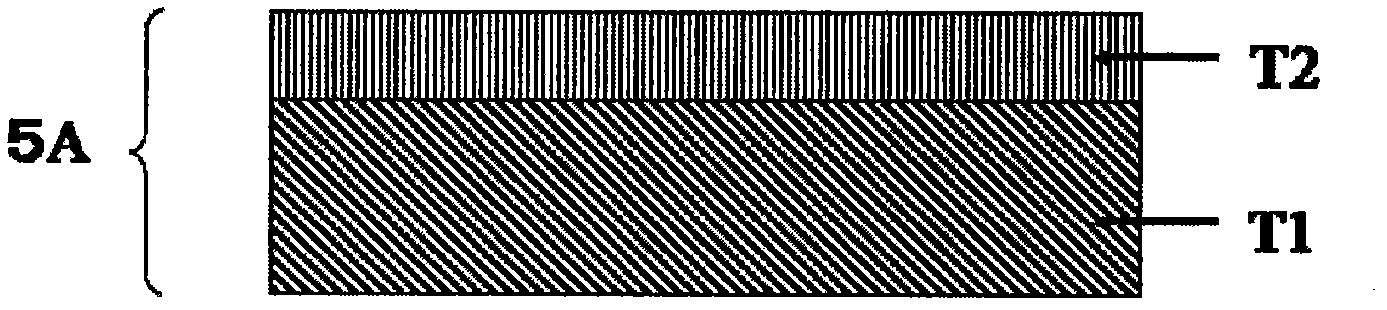

[0094] Hereinafter, examples of the present invention will be disclosed, and properties of the obtained metal laminated substrate will be described. A 200 mm wide, 18 μm thick high pressure rolled Cu foil (metal foil) and a 100 μm thick SUS316L plate (metal plate) were joined by surface activation bonding at room temperature, and then heat-treated at 200°C to 1000°C for 5 minutes. Metal build-up substrates.

[0095] Table 1 shows the ratio of the Cu (200) plane parallel to the Cu foil surface at this time, that is, the crystal orientation ratio (diffraction peak intensity ratio of the (200) plane of the θ / 2θ diffraction peak measured by X-ray diffraction: I (200) / ∑I (hkl) ×100(%)), and means that the (200) plane is parallel to the length direction , that is, ΔΦ° (the Φ scanning peak obtained in the Ni(111) pole diagram obtained by X-ray diffraction as an index of biaxial crystal orientation ( Average value of the half-value widths of the 4 peaks at α=35°)).

[0096] Compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com