Silicon based compliant substrate material possessing thin hafnium nitride compliant layer

A substrate material, hafnium nitride technology, applied in lasers, electrical components, circuits, etc., to achieve the effect of reducing residual stress, good crystal quality, and avoiding impurity pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

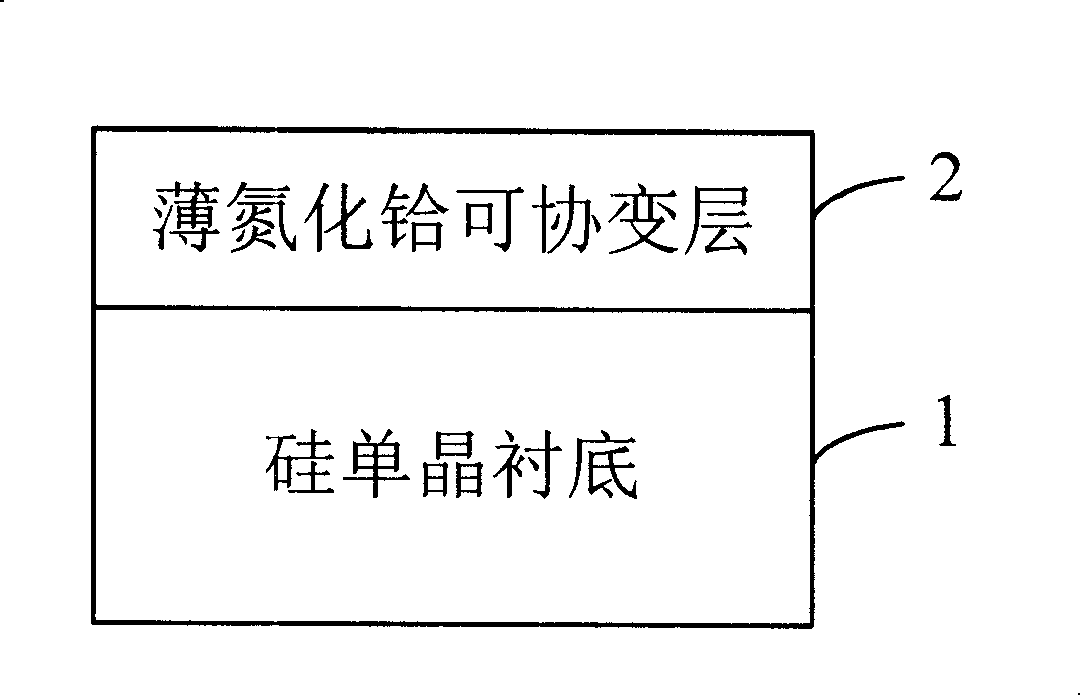

[0056] Using ion beam epitaxy, a 90nm thick and 45nm thick covariable hafnium nitride layer (samples E1 and F1) 2 was prepared and grown on a Si(111) substrate 1, forming two covariable layers with different thicknesses. The silicon base of the layer can be a co-variable substrate.

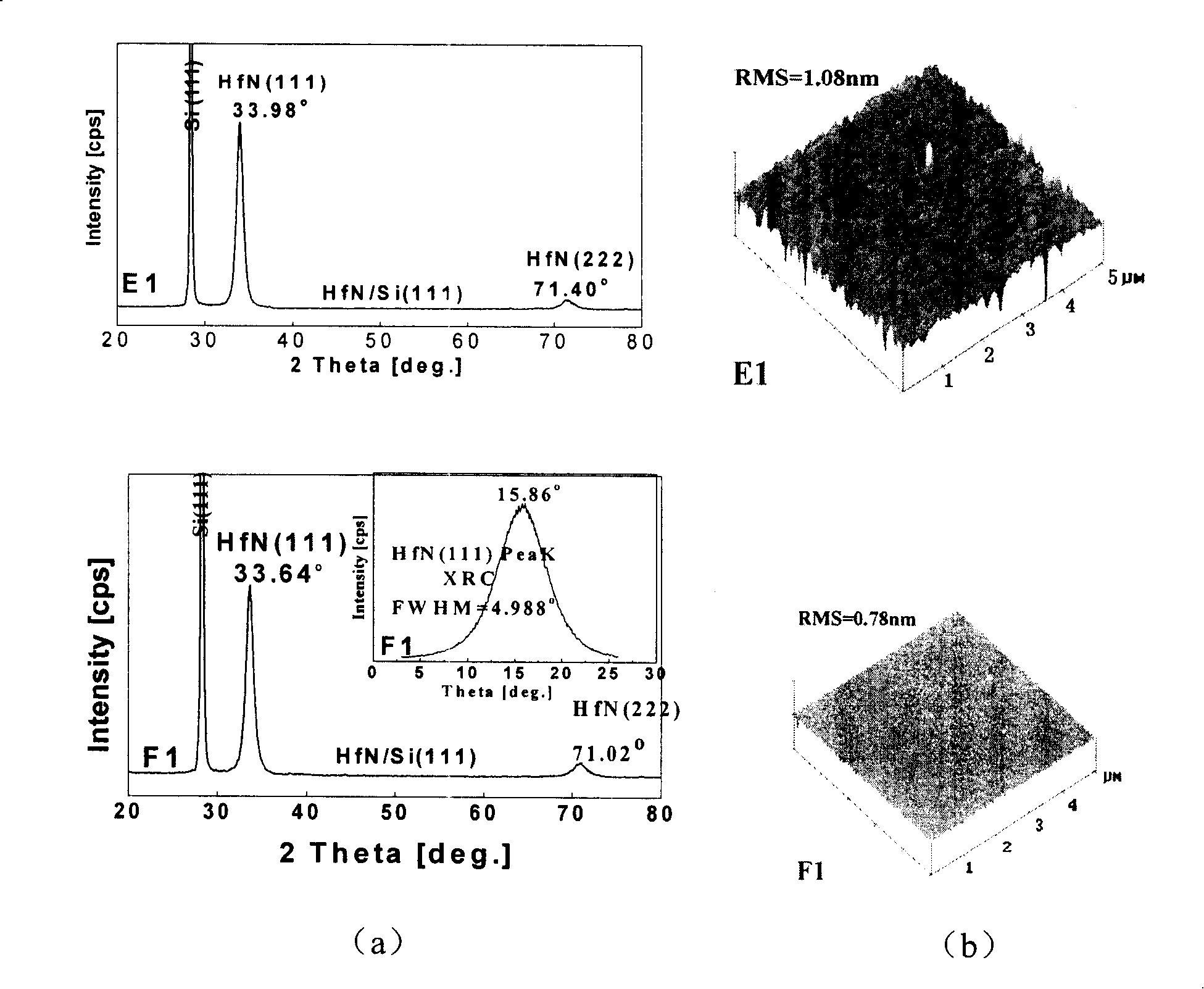

[0057] by figure 2 In (a) X-ray diffraction (XRD) and (b) atomic force surface topography test (AFM) test analysis results, it can be seen that the two thicknesses of thin hafnium nitride covariable layer 2 have cubic HfN (111 ) With a single preferred orientation, the surface is relatively smooth and flat. The root-mean-square roughness values of the AFM surface are 0.78nm and 1.08nm, respectively.

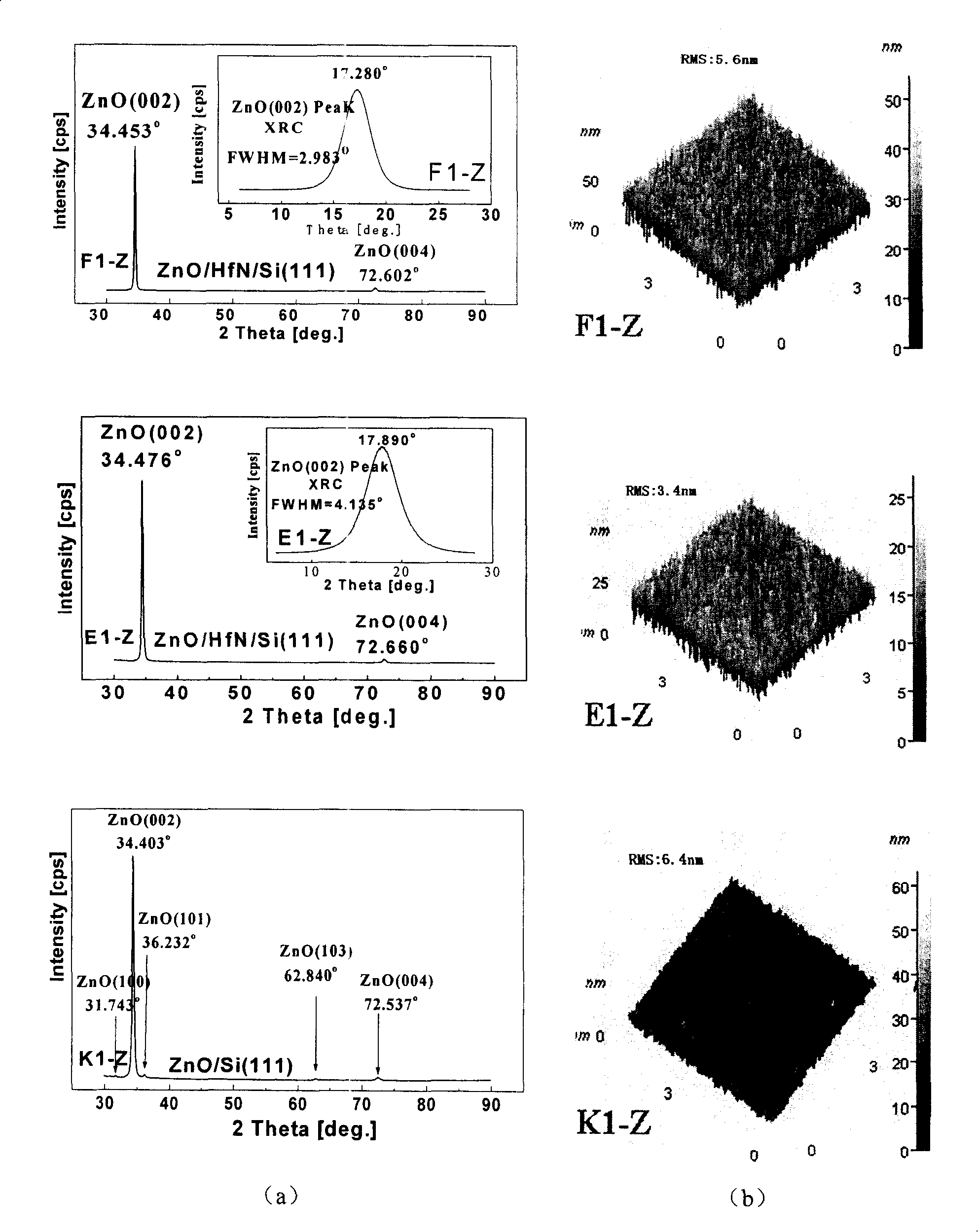

[0058] The same thickness of zinc oxide epitaxial film 3 is prepared by using the same magnetron sputtering process on these two kinds of silicon-based covariable substrates and ordinary Si(111) substrates.

[0059] by image 3 In (a) X-ray diffraction (XRD) test and analysis results can be seen: the ...

Embodiment 2

[0062] Using the ion beam epitaxy method, the 90nm thick and 18nm thick thin covariable hafnium nitride layers (samples E1 and F1) 2 grown on the Si (100) substrate 1 are formed, forming two coordinable layers with different thicknesses. The silicon-based variable layer can be a co-variable substrate.

[0063] by Figure 4 In (a) X-ray diffraction (XRD) and (b) atomic force surface topography test (AFM) test analysis results, it can be seen that the two thicknesses of thin hafnium nitride covariable layer 2 have cubic HfN (111 ) With a single preferred orientation, the surface is relatively smooth and flat. The root mean square roughness value of the G2 sample AFM is 0.20nm.

[0064] The same thickness of zinc oxide epitaxial film 3 is prepared by using the same magnetron sputtering process on these two kinds of silicon-based covariable substrates and ordinary Si(100) substrates.

[0065] by Figure 5 In (a) X-ray diffraction (XRD) test analysis results can be seen: the crystalline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com