Silicon based compliant substrate material for zinc oxide epitaxial film growth

A technology of epitaxial thin film and substrate material, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., to achieve the effect of improving surface morphology, improving crystallization quality, and good crystallization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

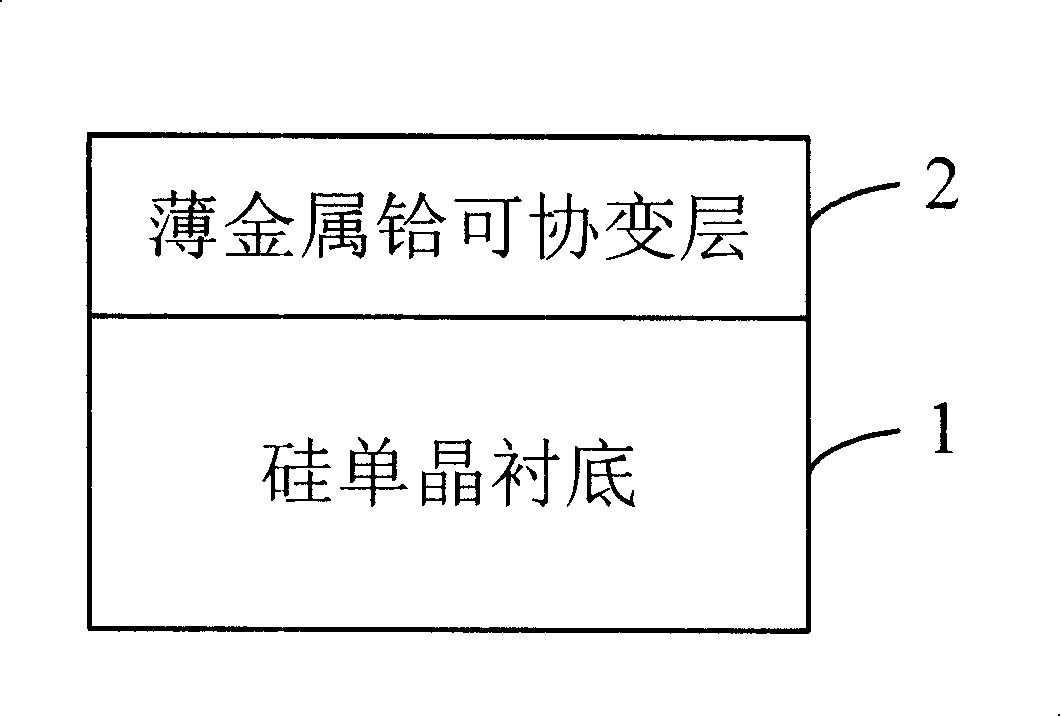

[0056] Using the ion beam epitaxy method, a 27nm-thick metal hafnium (α-Hf) compliant layer (sample P1) 2 was prepared and grown on a Si(111) substrate 1 to form a silicon-based compliant substrate.

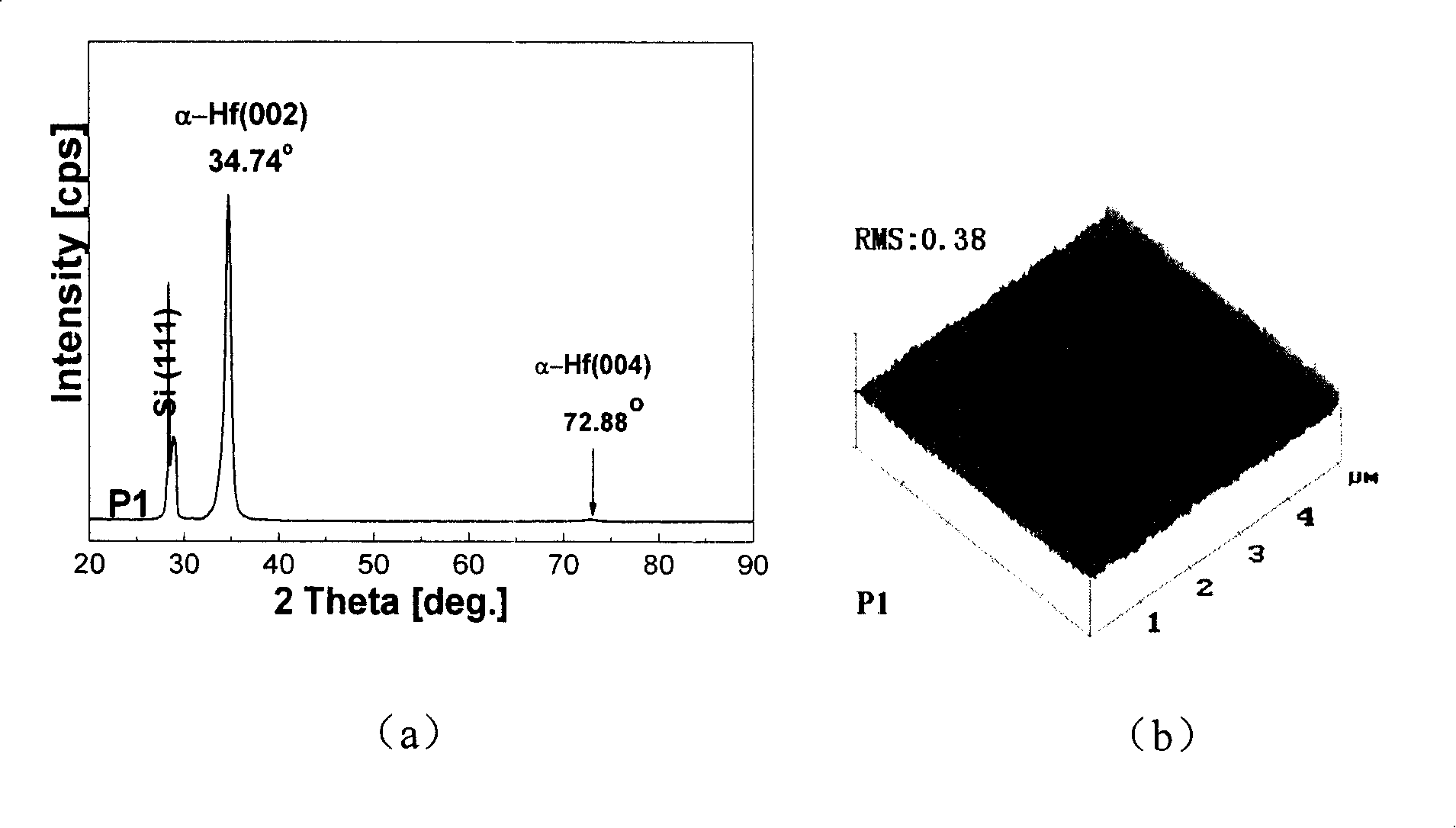

[0057] Depend on figure 2 In (a) X-ray diffraction (XRD) and (b) atomic force surface morphology (AFM) test analysis results, it can be seen that the prepared thin metal hafnium (α-Hf) covariable layer 2 has hexagonal α-Hf ( 100) single preferred orientation, the surface is relatively smooth and flat, and the root mean square roughness value of the surface by AFM is 0.38nm.

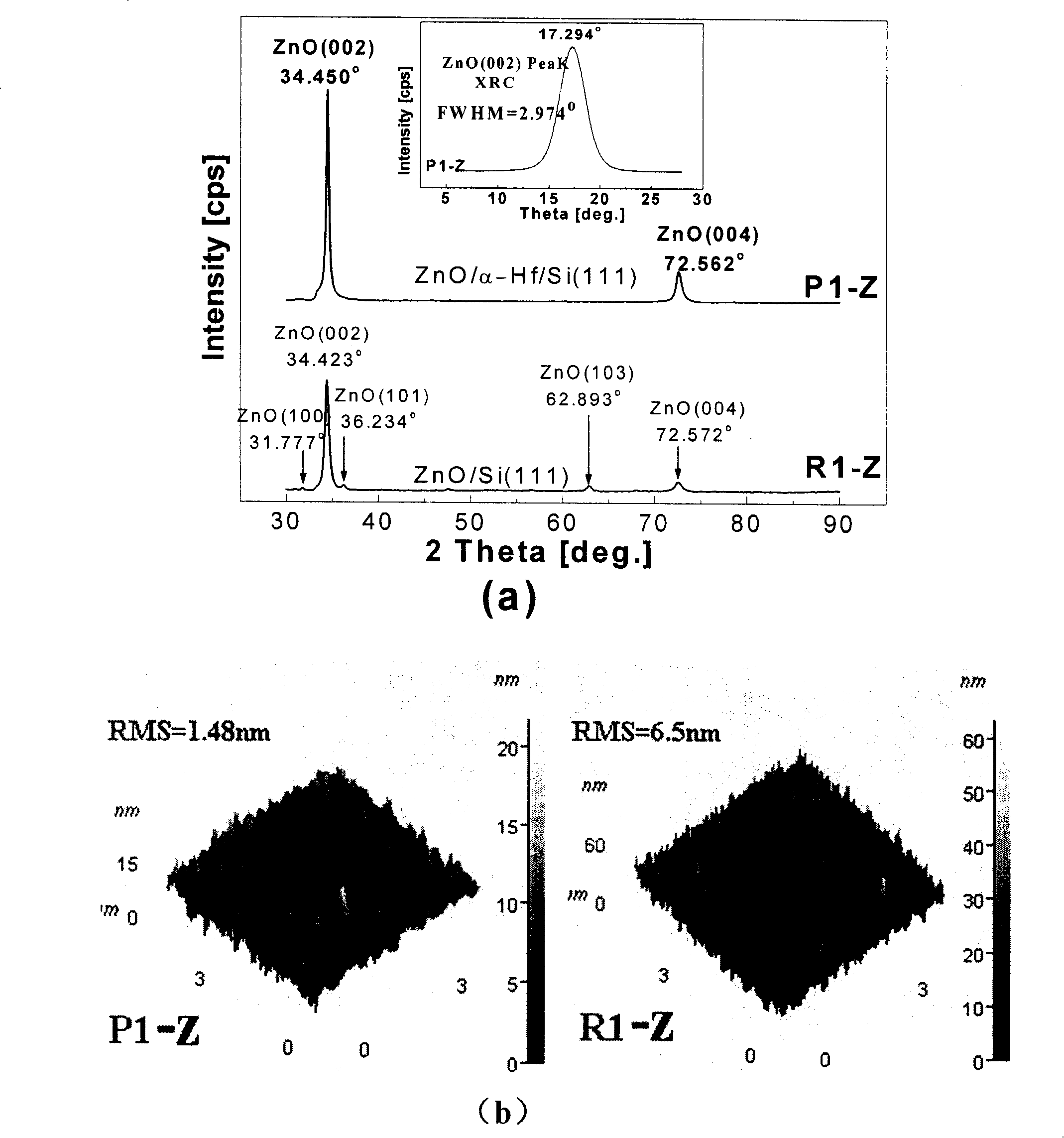

[0058] Zinc oxide epitaxial films 3 with the same thickness were prepared on the silicon-based variable substrate and the common Si(111) substrate by using the same magnetron sputtering process.

[0059] Depend on image 3 In (a) X-ray diffraction (XRD) test and analysis results, it can be seen that the zinc oxide epitaxial thin film sample R1-Z directly grown on the ordinary Si(111) substrate has poor cr...

Embodiment 2

[0062] A 27nm-thick metal hafnium compliant layer (sample P2) 2 was grown on a Si(100) substrate 1 by ion beam epitaxy, forming a silicon-based compliant substrate.

[0063] Depend on Figure 4 In (a) X-ray diffraction (XRD) and (b) atomic force surface morphology (AFM) test analysis results, it can be seen that the prepared thin metal hafnium covariable layer 2 has a single preferred orientation of hexagonal α-Hf(002) , the surface is relatively smooth and flat, and the root mean square roughness of the surface of the P2 sample AFM is 0.89nm.

[0064] Zinc oxide epitaxial films 3 with the same thickness were prepared on the silicon-based variable substrate and the common Si(100) substrate by using the same magnetron sputtering process.

[0065] Depend on Figure 5 In (a) X-ray diffraction (XRD) test and analysis results, it can be seen that the crystal quality of the zinc oxide epitaxial film sample T2-Z grown directly on the ordinary Si(100) substrate is obviously inferior...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com