III nitride semi-conductor material and growing method thereof

A nitride semiconductor and growth method technology, which is applied in the directions of semiconductor devices, semiconductor/solid-state device manufacturing, and semiconductor/solid-state device components, etc., can solve the problems of vertical sidewall inclination of grooves, increased manufacturing costs, and epitaxial growth failures, etc. Achieve the effect of easy peeling and lower growth cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

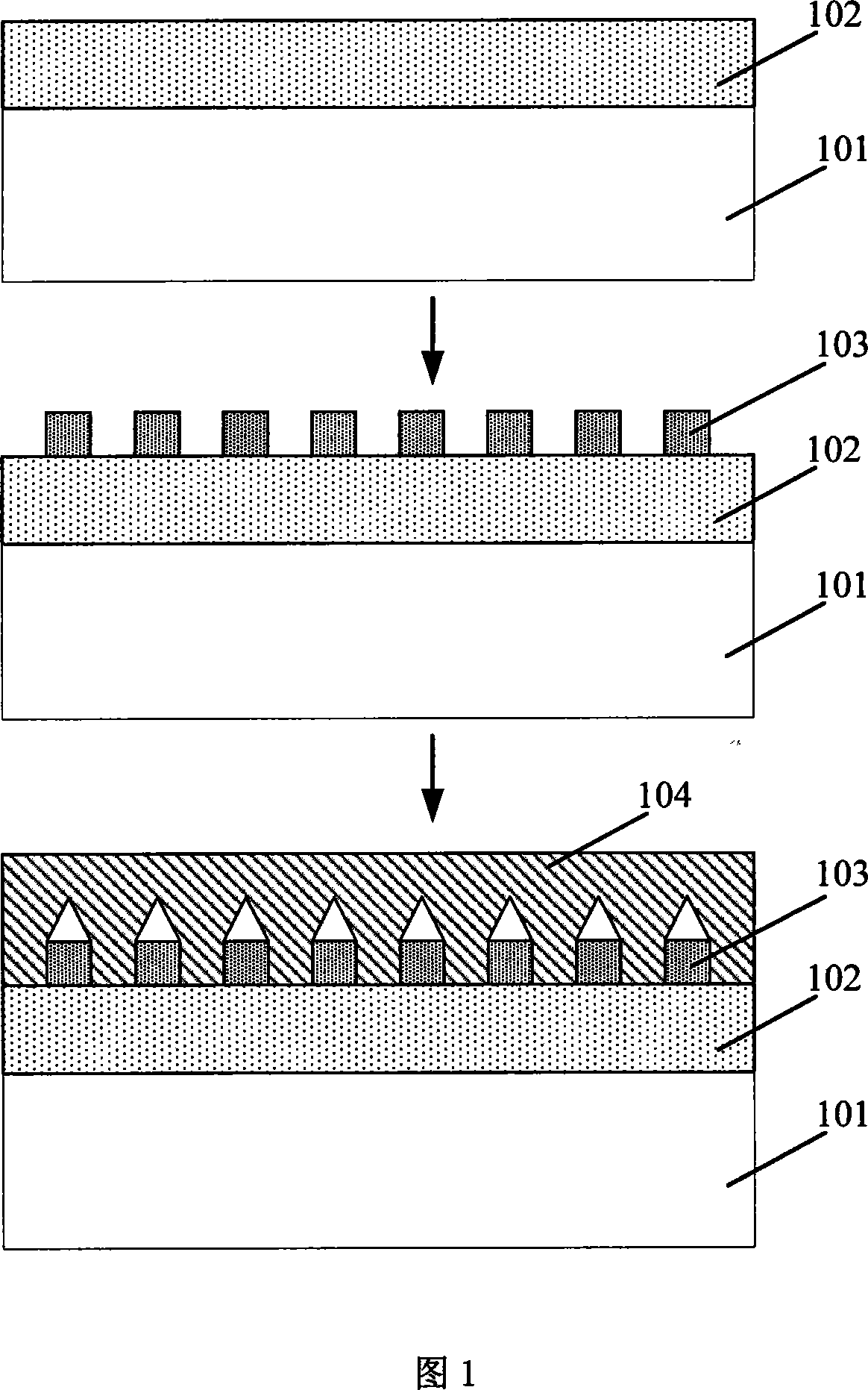

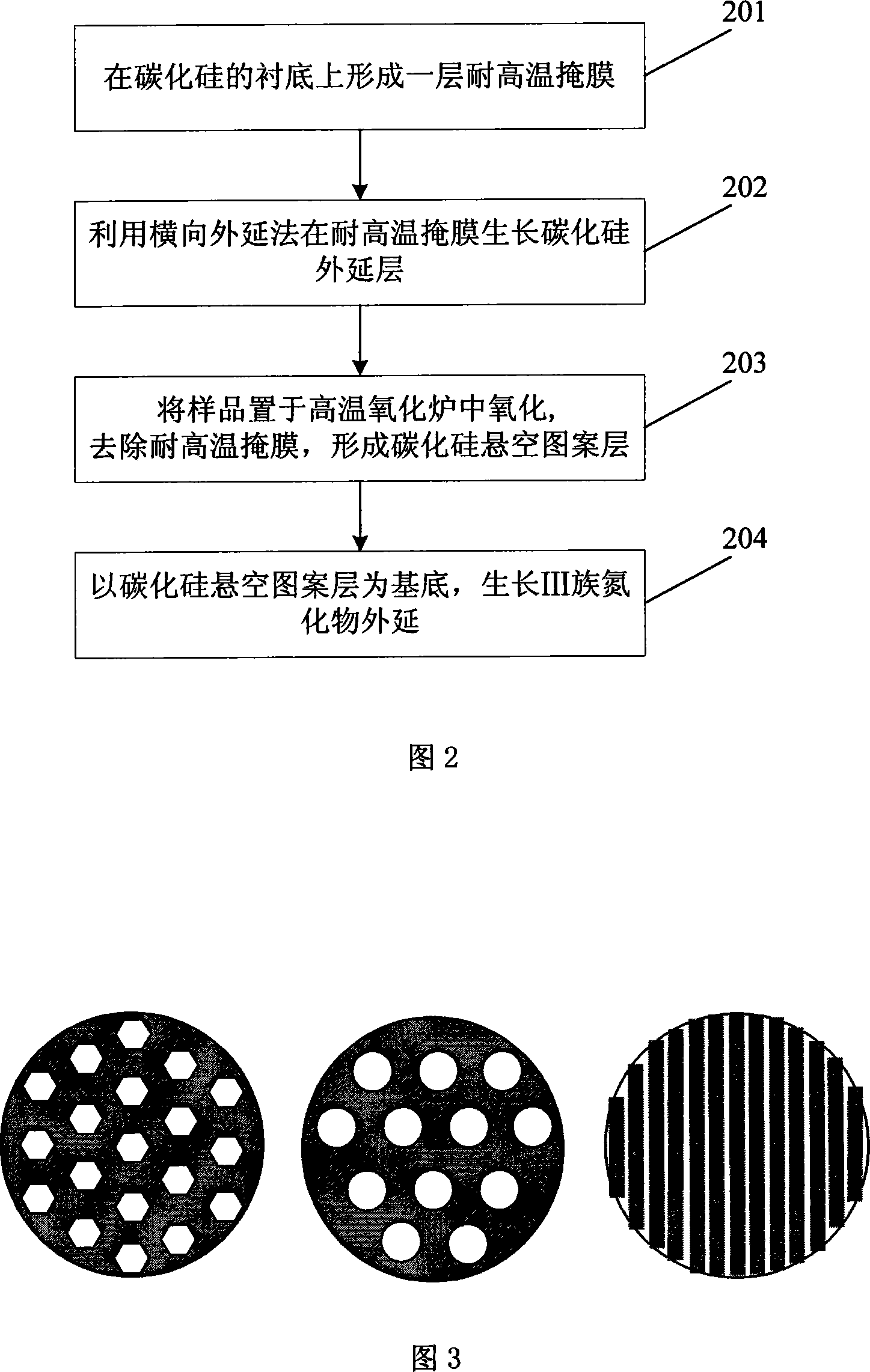

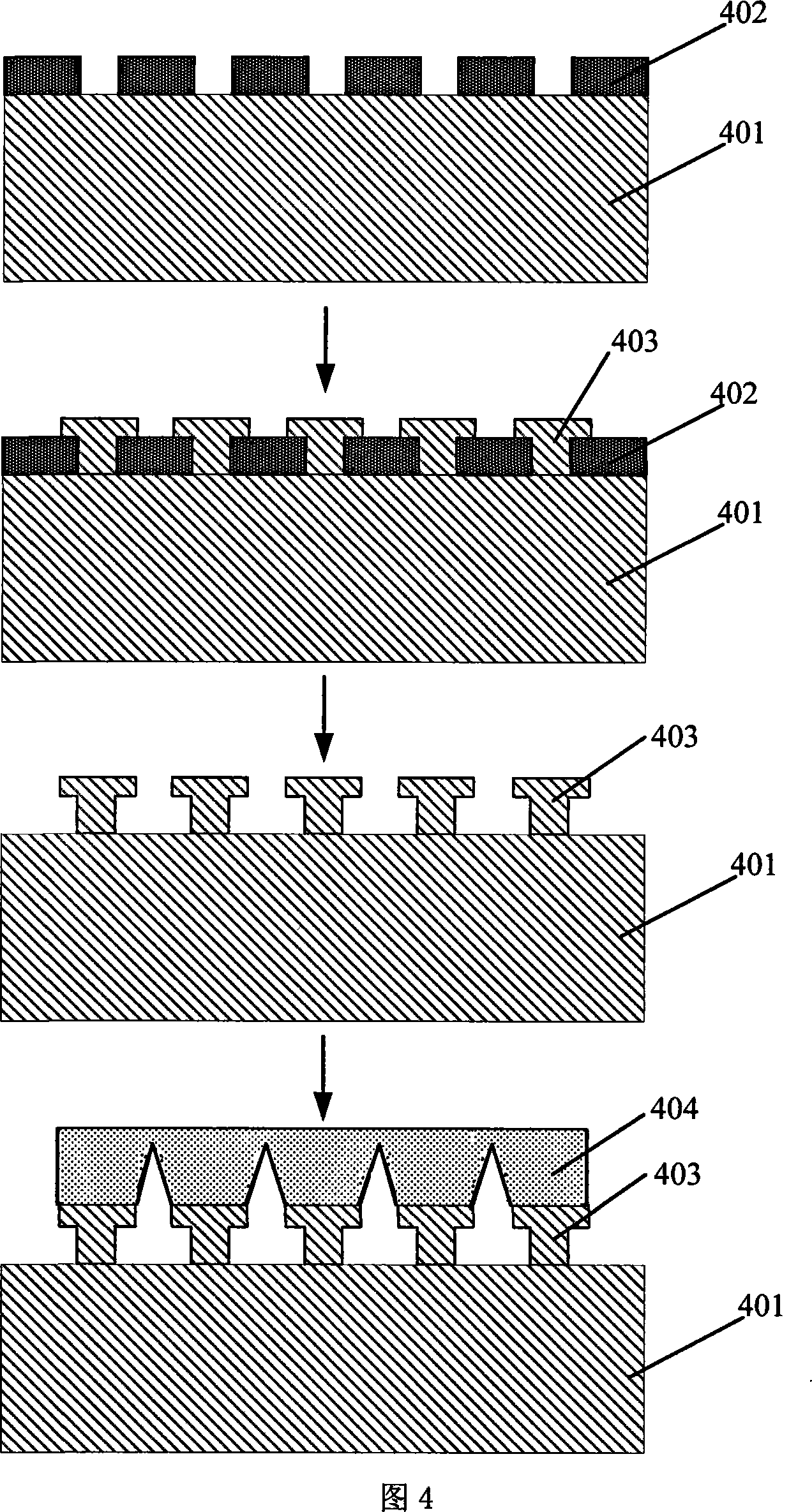

[0047] This embodiment provides a method for growing a Group III nitride semiconductor material, including:

[0048] First, a layer of high-temperature resistant mask is formed on the semiconductor substrate; then, an epitaxial layer homogeneous to the upper substrate is grown on the high-temperature resistant mask by lateral epitaxy; and then the above-mentioned semiconductor is placed in a high-temperature oxidation furnace Oxidation, removing the high-temperature resistant mask, forming a heterogeneous suspended pattern layer that is homogeneous with the above substrate or with a lattice matching coefficient of less than 3%; then, using the suspended pattern layer as a base, grow III-nitride epitaxy to form a III-group Nitride semiconductor materials.

[0049] Among them, group III nitrides include gallium nitride, aluminum nitride, aluminum gallium nitride, indium gallium nitride and aluminum indium gallium nitride, etc., and the substrate is usually silicon carbide, silic...

Embodiment 2

[0063] This embodiment provides a Group III nitride semiconductor material, which is grown by the method provided in Embodiment 1. Referring to FIG. 5 , the Group III nitride semiconductor material includes:

[0064] substrate 501;

[0065] The suspended pattern layer 502 is formed on the substrate 501 by epitaxy, and the material of the suspended pattern layer 502 is the same as that of the substrate 501;

[0066] The III-nitride epitaxy 503 is grown on the suspended pattern layer 502 by the III-nitride epitaxy technique.

[0067] Wherein, the substrate 501 is: silicon carbide, silicon, gallium arsenide or zinc oxide.

[0068] The advantages of the above technical solutions are as follows:

[0069] Due to the growth characteristics of PVT, the quality and surface polishing requirements of SiC are reduced, thereby reducing the growth cost; at the same time, since PVT itself is a low-cost growth method, the growth cost can be further reduced.

[0070] The lateral growth rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com