Crucible for growing silicon carbide monocrystal and having multiple growth cavities

A silicon carbide single crystal and growth cavity technology, which is applied in the growth of polycrystalline materials, single crystal growth, single crystal growth, etc., can solve the problem of increasing the cost of silicon carbide growth, the high price of silicon carbide wafers, and limiting the size of silicon carbide crystals. issues of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

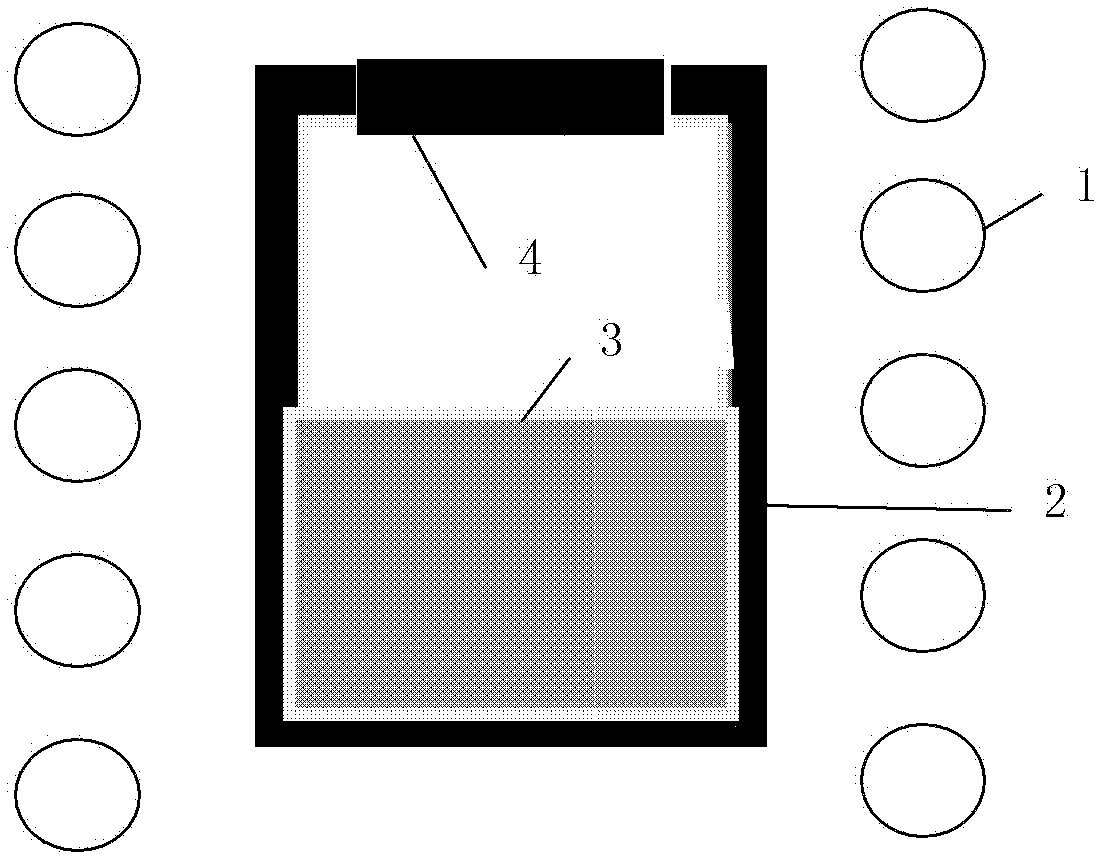

[0026] figure 1 It is the crucible used for growing SiC single crystal by conventional PVT technology. Wherein the thickness of the crucible wall of the crucible cavity is equal.

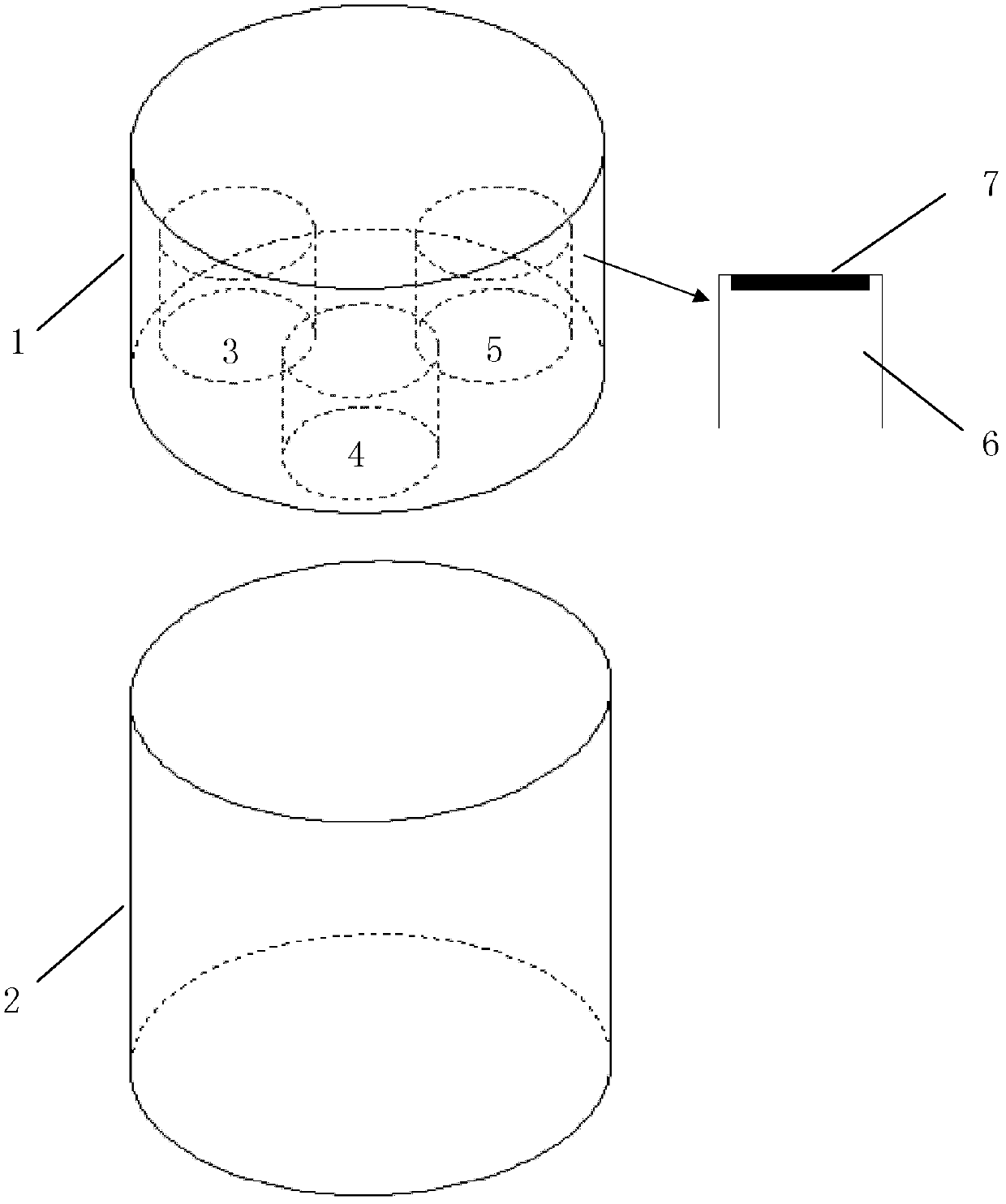

[0027] use figure 2 The crucible design shown is for PVT crystal growth. The crucible is divided into an upper chamber (growth chamber section) and a lower chamber (material chamber). The upper and lower chambers of the crucible (ie, the upper and lower sections) have the same outer diameter of 150 mm. The crucible has 3 independent growth chambers in total, the inner diameter of each growth chamber is 53mm, and the inner diameter of the feeding chamber is 130mm. The thickness of the top cover and the bottom cover of the crucible is 5 mm, and the thickness of the seed crystal holder for installing the seed crystal is 5 mm. The total height of the crucible is 200mm, wherein the height of the growth chamber section is 50mm, and the height of the feed chamber is 150mm. The two parts are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com