High-performance non-asbestos brake pad

A technology without asbestos and brake pads, applied in the field of auto parts, can solve the problems of irritation, brake failure, poor thermal conductivity, etc., and achieve the effect of reducing growth costs and reducing waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

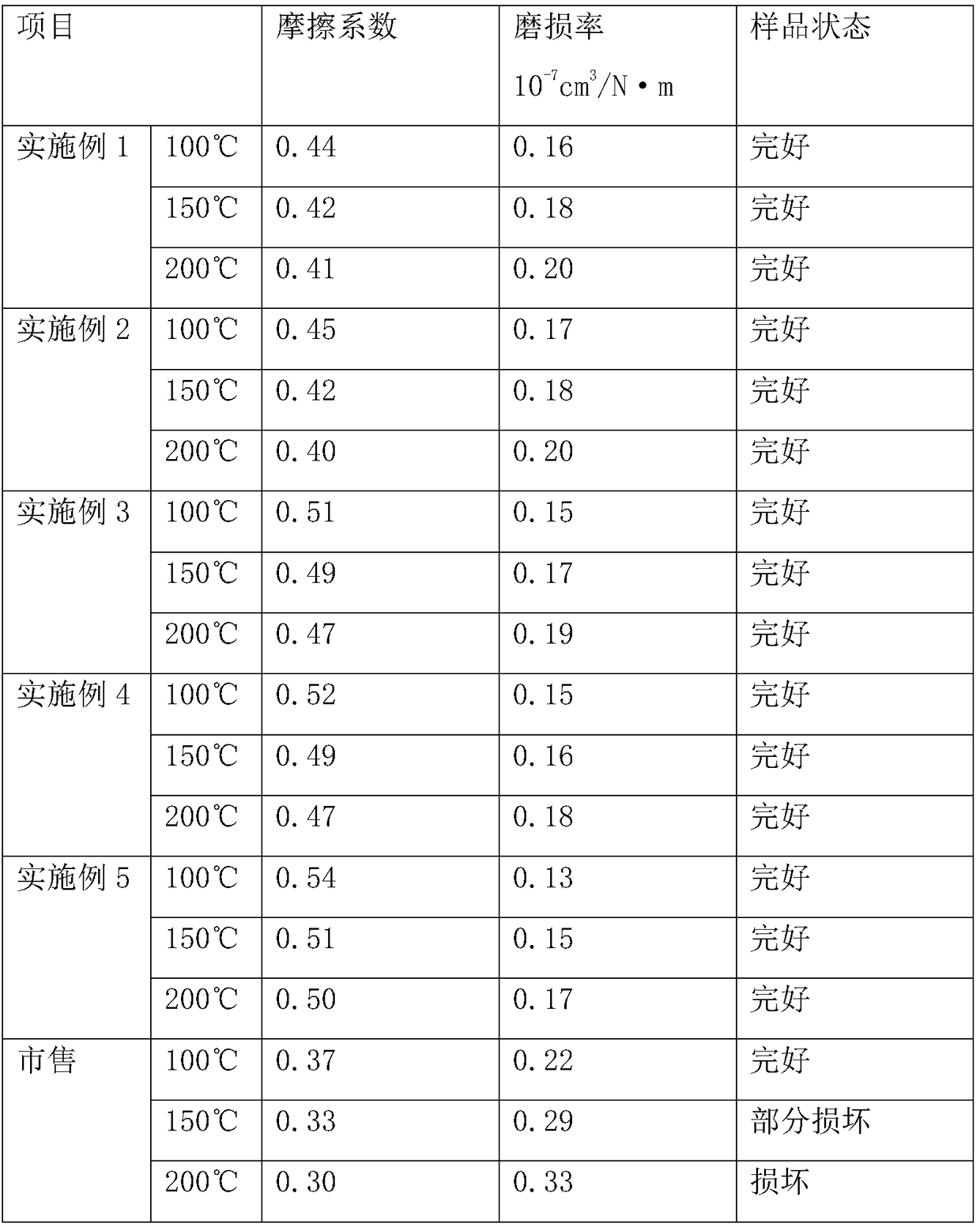

Examples

Embodiment 1

[0030] High-performance non-asbestos brake pads are made from at least the following parts by weight: 55 parts of fiber, 10 parts of resin, and 35 parts of friction powder.

Embodiment 2

[0032] High-performance non-asbestos brake pads are made of at least the following parts by weight: 40 parts of fiber, 15 parts of resin, and 45 parts of friction powder.

Embodiment 3

[0034] High-performance non-asbestos brake pads, made of at least the following parts by weight: 20 parts of mineral fiber, 10 parts of ceramic fiber, 5 parts of carbon fiber, 4 parts of melamine modified phenolic resin, 2 parts of cashew nut shell liquid modified phenolic resin , 8 parts of polyimide modified epoxy resin, 35 parts of friction powder, 10 parts of cashew nut shell liquid, 4 parts of flake graphite, 4 parts of silicon carbide, 1 part of graphene, 2 parts of carbon black, 1 part of molybdenum disulfide, 2 parts of barium sulfate, 1 part of zinc oxide, 2 parts of acicular wollastonite, 1 part of barite, 2 parts of kyanite, 1 part of zircon powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com