Preparation method of transferable perovskite oxide piezoelectric texture film for promoting crystallization by graphene

A perovskite oxide, a technology to promote crystallization, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of poor quality, easy oxidation of silicon surface, and difficulty in meeting the crystallization temperature of ferroelectric thin films And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] see figure 1 , the preparation method of graphene-promoted crystallization transferable perovskite oxide piezoelectric texture film of the present invention comprises the following steps:

[0028] Step 1: Select graphene as the intermediate layer material between the oxide and the substrate;

[0029] Step 2: Use pulsed laser deposition to grow the film, the specific method is as follows:

[0030] 2-1) Install the perovskite oxide target and graphene substrate to be grown in a vacuum chamber, and pump the air pressure in the vacuum chamber to 5×10 -4 Below Pa, to remove the pollution impurities adsorbed on the graphene surface;

[0031] 2-2) Heating the graphene substrate to 500°C to 800°C, feeding oxygen into the vacuum chamber, and controlling the air pressure between 10Pa and 20Pa;

[0032] 2-3) Use a pulsed laser to control the laser energy density at 1.5J / cm 2 ~3J / cm 2 In between, use a lens to focus the laser on the surface of the barium titanate ceramic targe...

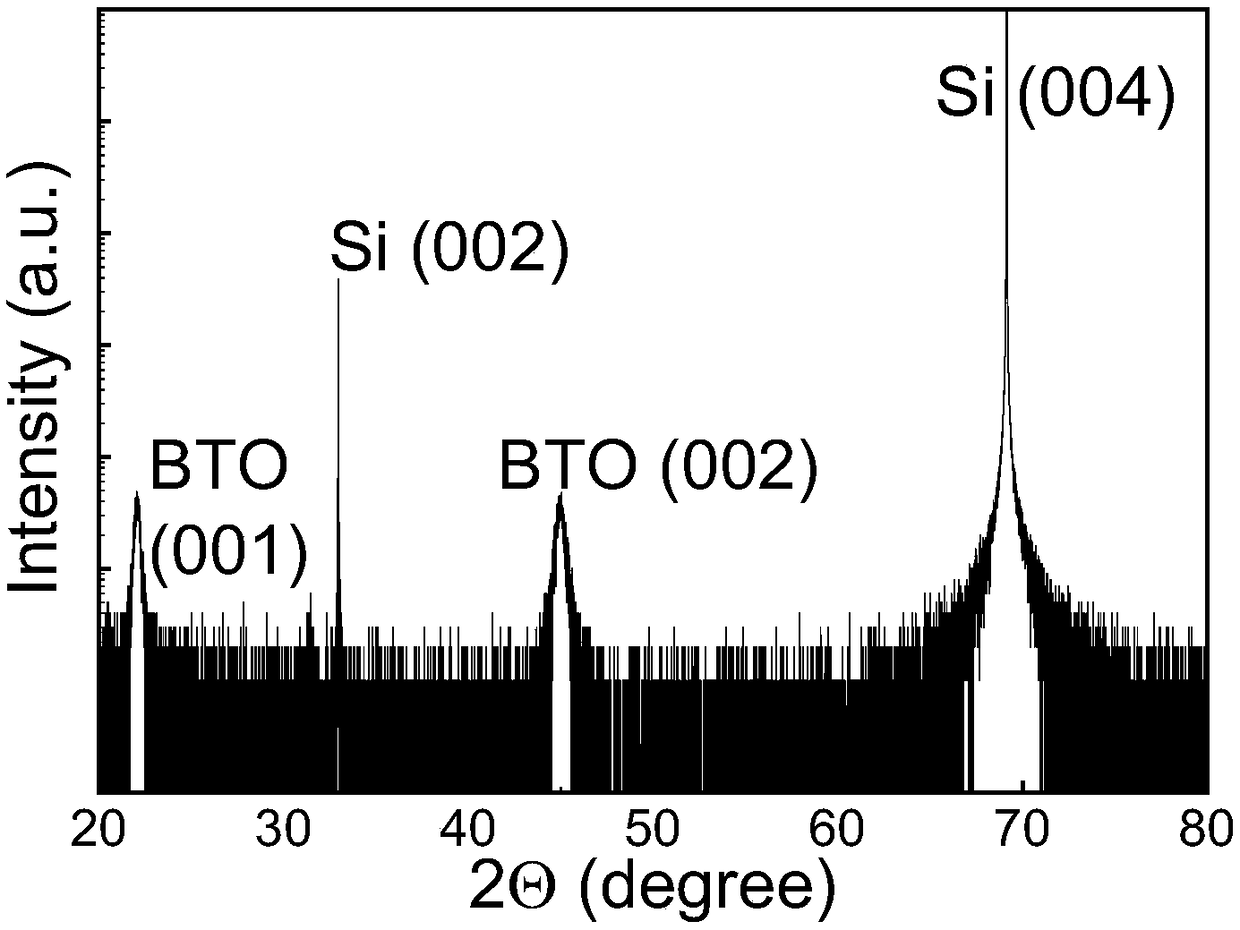

Embodiment 1

[0037] 1) Barium titanate ceramic target and graphene-coated SiO 2 / Si substrate is installed in the cavity of pulsed laser deposition equipment;

[0038] 2) Use a vacuum pump to pump the pressure in the chamber to the back pressure of 5×10 -4 Pa;

[0039] 3) heating the silicon-based graphene substrate to 650°C;

[0040] 4) Introduce high-purity oxygen and adjust the air pressure at 10Pa;

[0041] 5) Cover the substrate with a baffle, turn on the laser, adjust the laser to focus on the surface of the barium titanate ceramic target, and perform pre-sputtering to remove impurities on the target surface;

[0042] 6) Adjust the laser energy density to 1.8J / cm 2 , control the frequency at 5Hz, open the baffle in front of the substrate, and start film growth;

[0043] 7) According to the required film thickness, after waiting for a certain growth time, turn off the laser and stop the film growth;

[0044] 8) Turn off the vacuum pump, fill the cavity with enough oxygen, and ad...

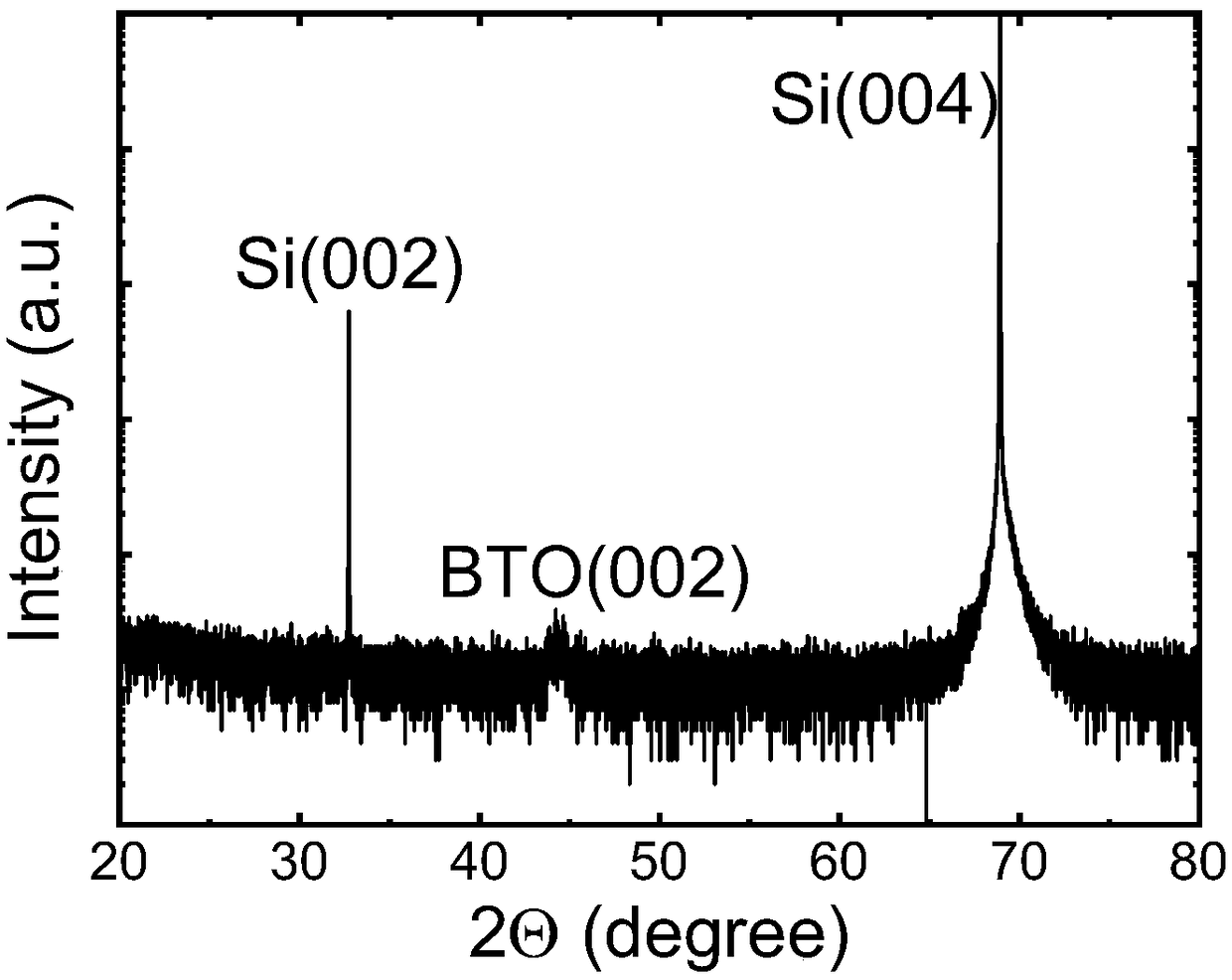

Embodiment 2

[0048] 1) Barium titanate ceramic target and graphene-coated SiO 2 / Si substrate is installed in the cavity of pulsed laser deposition equipment;

[0049] 2) Use a vacuum pump to pump the pressure in the chamber to the back pressure of 5×10 -4 Pa;

[0050] 3) heating the silicon-based graphene substrate to 500°C;

[0051] 4) Introduce high-purity oxygen and adjust the air pressure at 10Pa;

[0052] 5) Cover the substrate with a baffle, turn on the laser, adjust the laser to focus on the surface of the barium titanate ceramic target, and perform pre-sputtering to remove impurities on the target surface;

[0053] 6) Adjust the laser energy density to 1.5J / cm 2 , control the frequency at 1Hz, open the baffle in front of the substrate, and start film growth;

[0054] 7) According to the required film thickness, after waiting for a certain growth time, turn off the laser and stop the film growth;

[0055] 8) Turn off the vacuum pump, fill the cavity with enough oxygen, and ad...

PUM

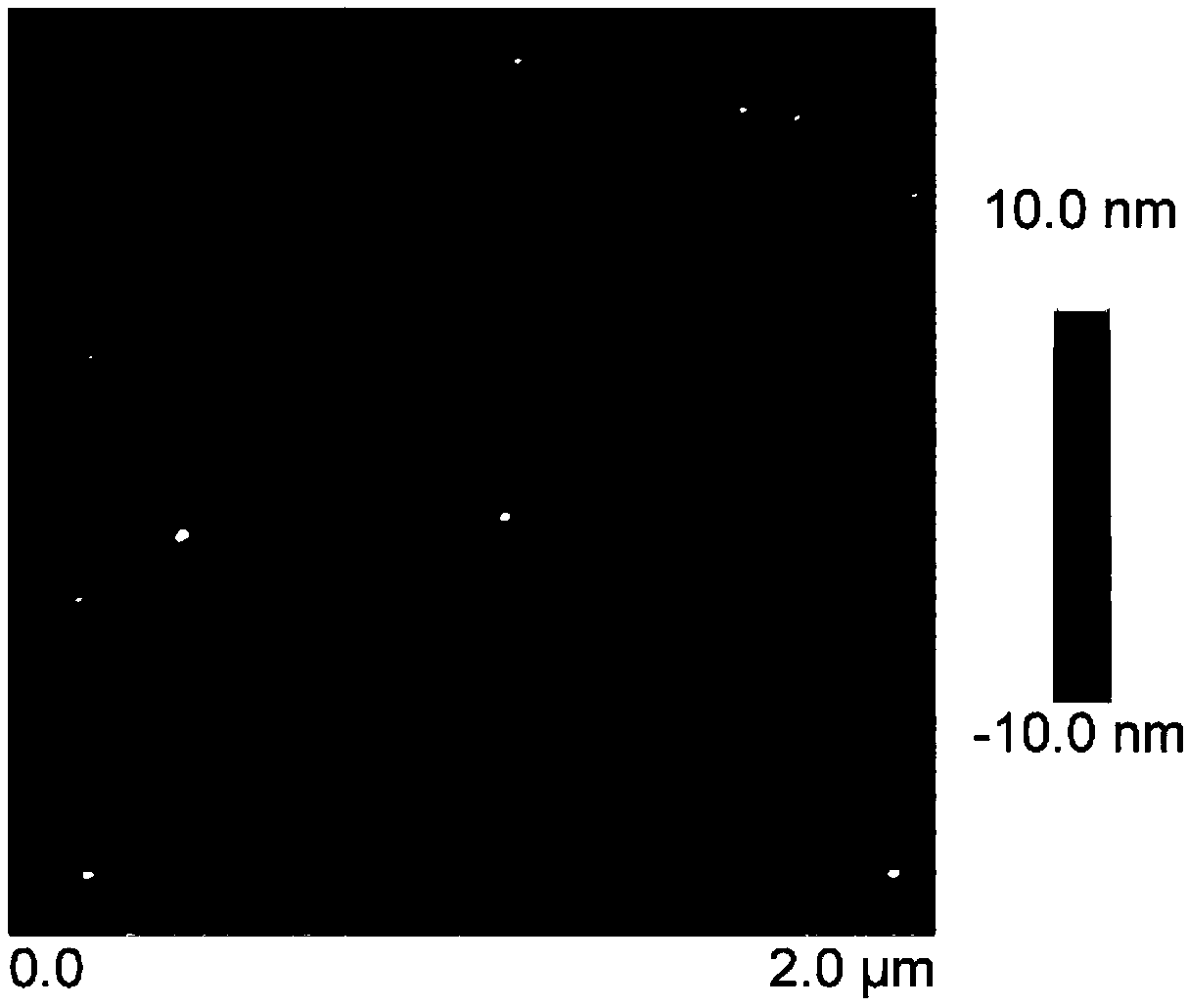

| Property | Measurement | Unit |

|---|---|---|

| Root mean square roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com