ZnxCo1-x-ZIF-67 membrane and preparation method thereof

A technology of znxco1-x-zif-67 and ZIF-8, applied in the field of preparation of metal-organic framework membrane materials, can solve problems affecting compactness, integrity and gas separation performance, insufficient bonding between seeds and supports, and crystallinity. The problem of uneven particle size, etc., achieves the effect of excellent gas separation performance, great theoretical and practical significance, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

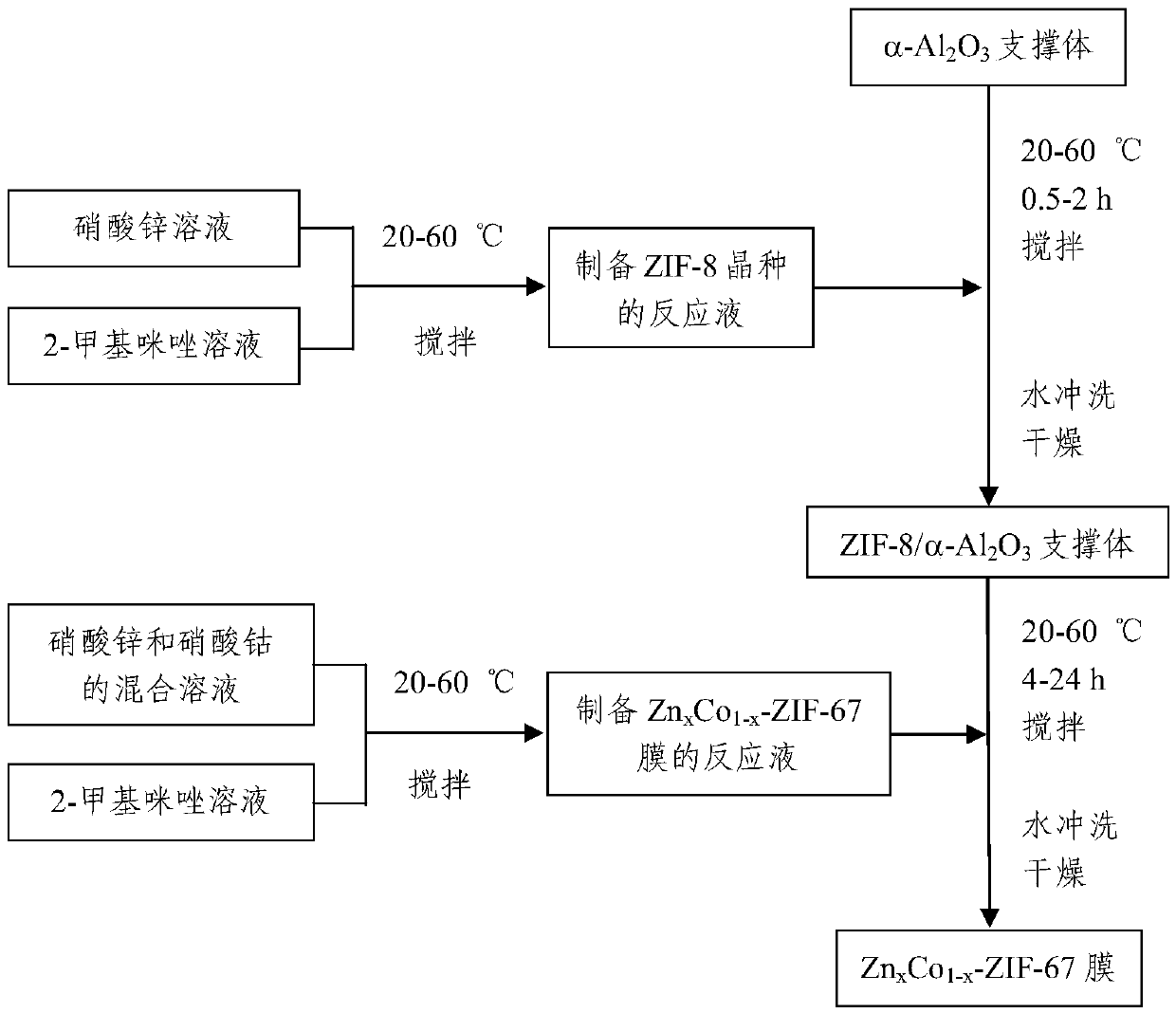

[0045] The embodiment of the present invention provides a Zn x co 1-x -Preparation method of ZIF-67 film, such as figure 2 As shown, the specific steps are as follows:

[0046] Add an appropriate amount of Zn(NO 3 ) 2 ·6H 2 O and 2-methylimidazole (Hmim) were dissolved in deionized water respectively to form equal-volume solutions, and the two solutions were mixed, stirred evenly, and then placed in a polytetrafluoroethylene kettle as a reaction solution for growing ZIF-8, wherein two The molar ratio of valence zinc (Zn(II)) to Hmim is 1:72, and the concentration of Zn(II) is 9.5mmol / L. The porous alumina sheet-like supports that have been polished with sandpaper of different meshes were placed in the reaction solution, and reacted at 30° C. for 1 h. The sample was taken out, washed with deionized water several times and dried at room temperature to obtain a support with ZIF-8 seed crystals grown on the surface. The average size of the ZIF-8 seeds on the surface of the...

Embodiment 2

[0051] The embodiment of the present invention provides a Zn x co 1-x -The preparation method of ZIF-67 film, concrete steps are as follows:

[0052] The preparation process of the reaction solution for growing the seed layer and the molar ratio of divalent zinc (Zn(II)) to Hmim in the reaction solution, and the concentration of Zn(II) are all consistent with those in Example 1. The treated porous alumina sheet-like support was placed in the reaction solution, and reacted at 30° C. for 2 hours. The sample was taken out, washed with deionized water several times and dried at room temperature to obtain a support with ZIF-8 seed crystals grown on the surface, and the average size of the ZIF-8 seed crystals was about 1 μm. The support is placed on the growth Zn x co 1-x - In the reaction solution of ZIF-67, the preparation process and composition of the reaction solution are consistent with that of Example 1, reacted at 30°C for 8h, took out the sample, dried at room temperatu...

Embodiment 3

[0054] Adopt the conditions in embodiment 1 to grow ZIF-8 seed crystals on the support body surface, place it in the growth Zn x co 1-x -In the reaction solution of ZIF-67, wherein, the molar ratio of the total amount of divalent zinc (Zn(II)) and divalent cobalt (Co(II)) to Hmim is 1:72, Zn(II) and Co( The total concentration of II) is 10mmol / L, the molar ratio of Zn(II) to Co(II) is 3:1, react at 30°C for 8h, take out the sample, and dry at room temperature, the obtained Zn x co 1-x -The ZIF-67 film has defects under the scanning electron microscope, and there are gaps between the grains, and its H 2 / CO 2 , H 2 / N 2 , H 2 / CH 4 The separation coefficients are 4.3, 3.9, 2.7, which are lower than the ideal gas separation coefficient of the Knudsen diffusion mechanism, and the separation performance is poor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com