Method for measuring metal bar textures

A technology of metal rods and the same metal, applied in the direction of measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve the physical properties of difficult materials, the lack of macroscopic representativeness and statistics, and the difficulty of sample preparation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

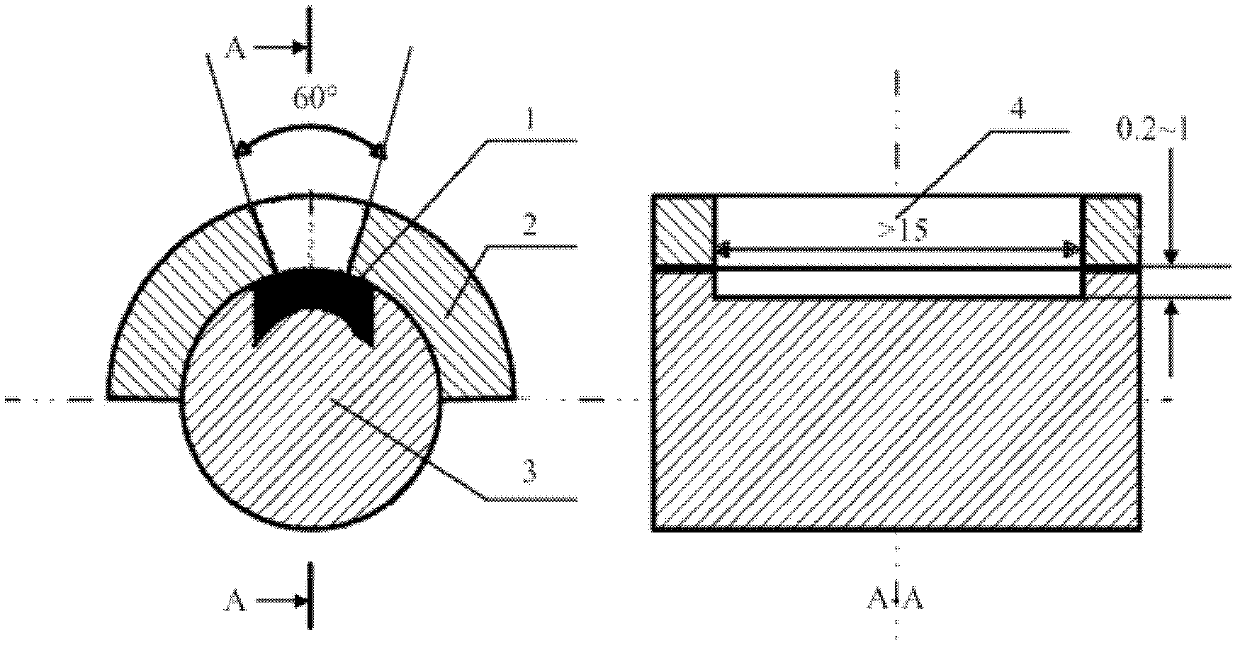

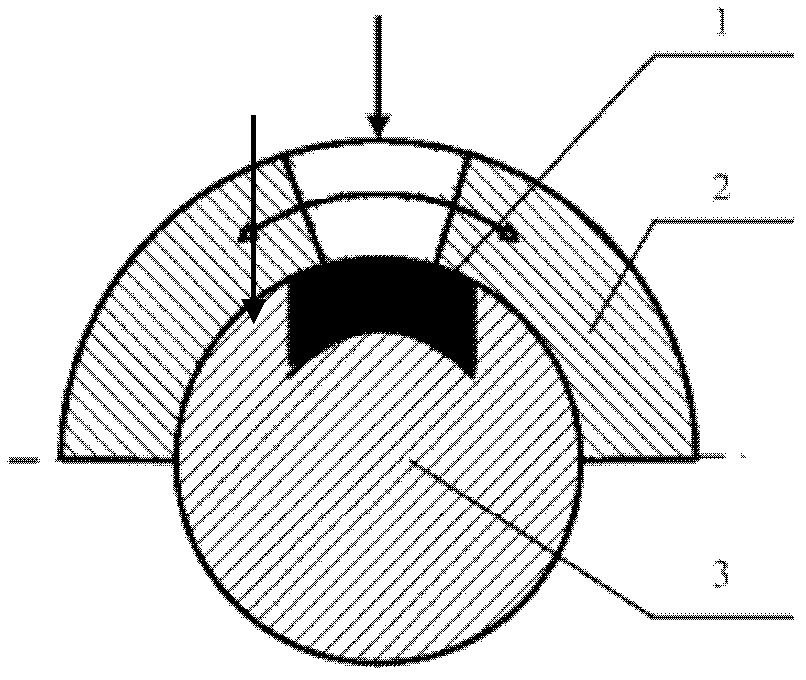

[0026] Determination of the texture of titanium alloy rods: the diameter of titanium alloy rod samples is 16mm. The non-textured standard sample is titanium powder below 600 mesh, with a purity of 99.8%. Put the titanium powder into the filling area of the cylindrical sample holder little by little. The projected size of the filling area is 8X15mm, and the depth is 0.5mm. The material is the same, and the powder is compacted using a semi-cylindrical female mold. The surface of the powder standard sample is required to have the same curvature as the bar, and it is used as a non-textured standard sample. Using the same test conditions, on the X-ray diffractometer, fix the goniometer in the diffraction direction of the {0002} crystal plane, and measure the diffraction intensity, tilt angle and χ from 0° to 75°, rotation angle From 0° to 360°, the step size is 5°. Plot the {0002} pole figure with corrected strength. Continue to measure {11-20}, {1-101}, {1-102} and {1-103} p...

Embodiment 2

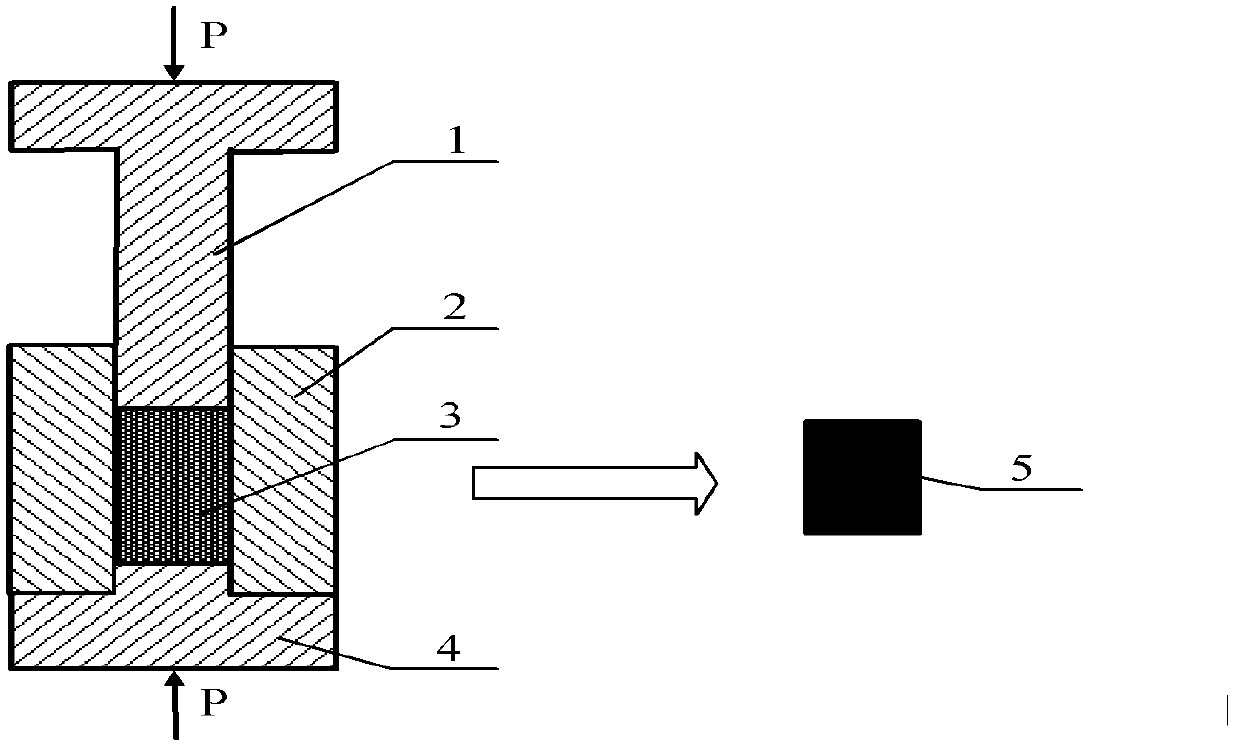

[0028] Determination of the texture of titanium alloy rods: the diameter of titanium alloy rod samples is 19.050mm. The non-textured standard sample is titanium powder below 600 mesh, with a purity of 99.8%. The titanium powder is put into a cylindrical molding mold little by little. The diameter of the cavity is the same as that of the bar sample, and the pressing pressure is 200MPa. After demolding, the obtained The standard sample is a cylindrical compact with a length of 20 mm and a diameter of 19.050. Using the same test conditions, on the X-ray diffractometer, fix the goniometer in the diffraction direction of the {0002} crystal plane, and measure the diffraction intensity, tilt angle and χ from 0° to 75°, rotation angle From 0° to 360°, the step size is 5°. Plot the {0002} pole figure with corrected strength. Continue to measure {11-20}, {1-101}, {1-102} and {1-103} pole figures according to the above method. The omnipolar figure and orientation distribution functi...

Embodiment 3

[0030]Determination of the texture of the aluminum alloy bar: the diameter of the cold-rolled aluminum alloy bar sample is 10mm. The non-textured standard sample is aluminum powder below 600 mesh, with a purity of 98%. Put the aluminum powder into the filling area of the cylindrical sample holder little by little. The projection size of the filling area is 3X15mm, and the depth is 0.2mm. The material is the same, and the powder is compacted using a semi-cylindrical female mold. The surface of the powder standard sample is required to have the same curvature as the bar, and it is used as a non-textured standard sample. Using the same test conditions, on the X-ray diffractometer, fix the goniometer on the diffraction direction of the {110} crystal plane, and measure the diffraction intensity, tilt angle and χ from 0° to 75°, rotation angle From 0° to 360°, the step size is 5°. Plot a {110} pole figure with corrected intensities. Continue to measure {200} and {211} pole fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com