Polycrystalline gallium-nitride self-supporting substrate and light-emitting element using same

A gallium nitride and gallium nitride-based technology, applied in the field of polycrystalline gallium nitride self-supporting substrates, can solve the problems of inability to form electrodes, prone to dislocations, inconsistent lattice constants and thermal expansion rates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

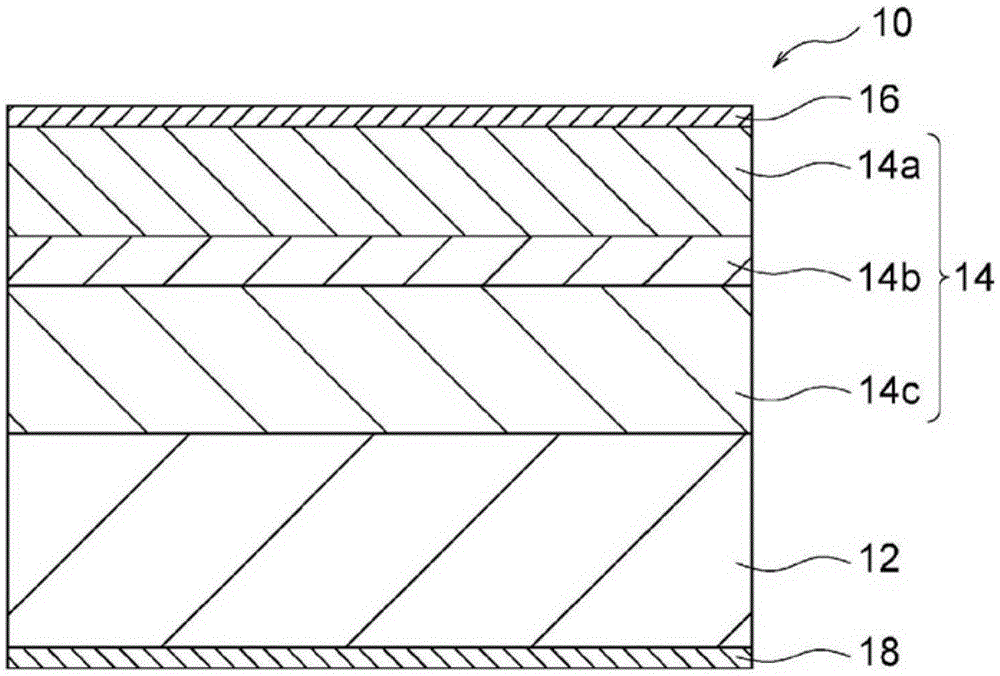

[0016] Polycrystalline Gallium Nitride Free-standing Substrate

[0017] The gallium nitride substrate of the present invention may have the form of a self-supporting substrate. The "self-supporting substrate" in the present invention refers to a substrate that can be handled or used as a solid object without deforming or breaking due to its own weight during handling or use. The polycrystalline gallium nitride self-supporting substrate of the present invention can be used as a substrate of various semiconductor devices such as a light-emitting element, and can also be used as an electrode (which can be a p-type electrode or an n-type electrode), a p-type layer, an n-type electrode, etc. Parts or layers other than base materials such as molded layers. It should be noted that in the following description, the advantages of the present invention are described by taking light-emitting elements as one of the main applications as an example, but the same or similar advantages are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com