Cubic System Material texture quantitative test and analysis method

A technology of test analysis and cubic system, which is applied in the direction of material analysis, material analysis, and measuring devices using wave/particle radiation, and can solve the problem of not being able to give the percentage of texture components and quantitatively giving texture components volume percentage etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0062] 1. The pole figure measurement method adopted is still the three incomplete pole figure data measured by the "reflection method" commonly used in China and internationally. Using the three incomplete pole figure data, select the "two-step method" to calculate the ODF Coefficient Wlmn;

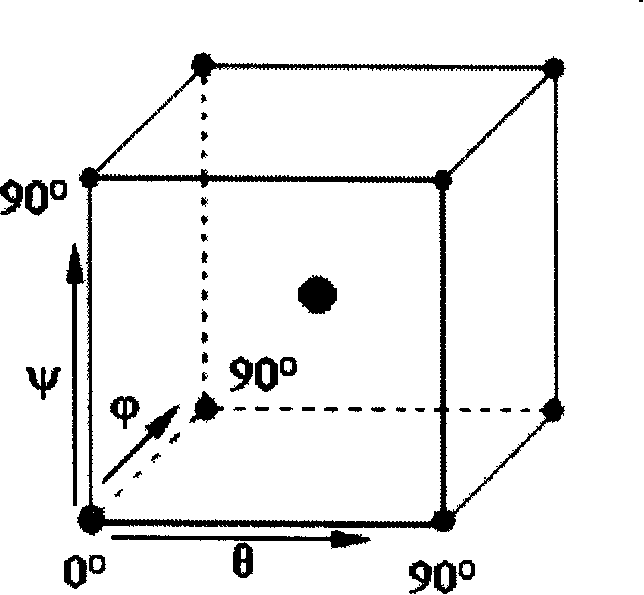

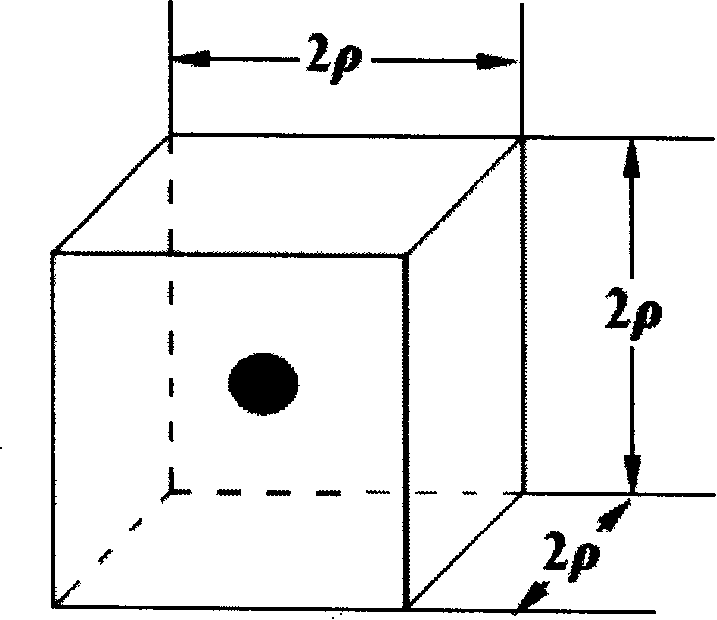

[0063] 2. Divide the Euler space at an interval of 1°, calculate the orientation density of the entire Euler space, and use formula (2) to define the Euler angle as 1°;

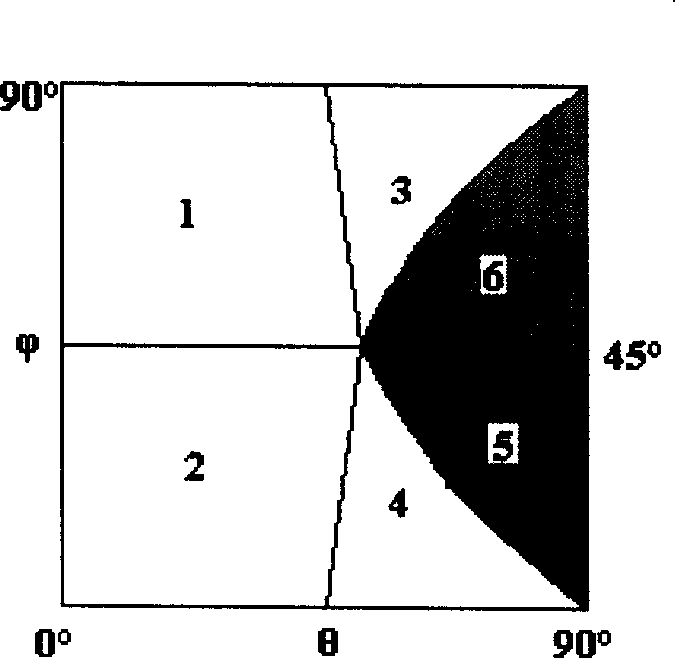

[0064] 3. Select regions 5 and 6 in the asymmetric sub-Eulerian space as the quantitative range of texture components (such as figure 1 ), and convert the orientation beyond zone 5 and zone 6 in the form of equivalent orientation; the calculated surface texture components should satisfy formulas (14) and (15).

[0065] -HU-KV+LW=0(14)

[0066] HU'-KV'+LW'=0(15)

[0067] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com