Method for quick testing data of pole figure for deep drawn sheet plate made from aluminium alloy

A technology of deep drawing and aluminum alloy, which is applied in the field of X-ray inspection and can solve the problems of unsuitable detection of stamping aluminum plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

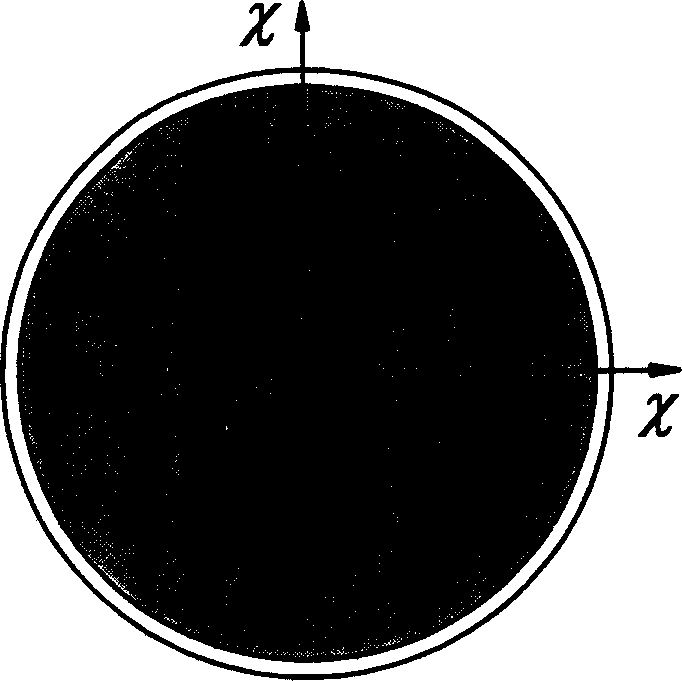

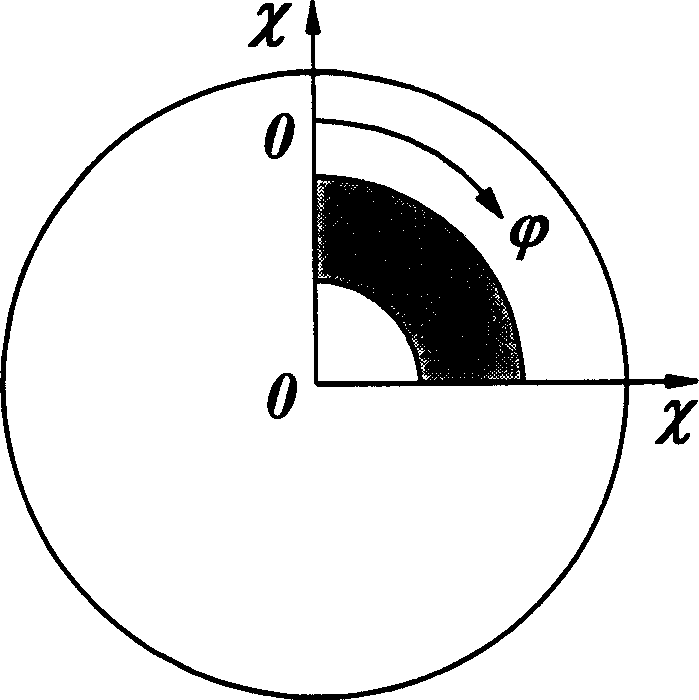

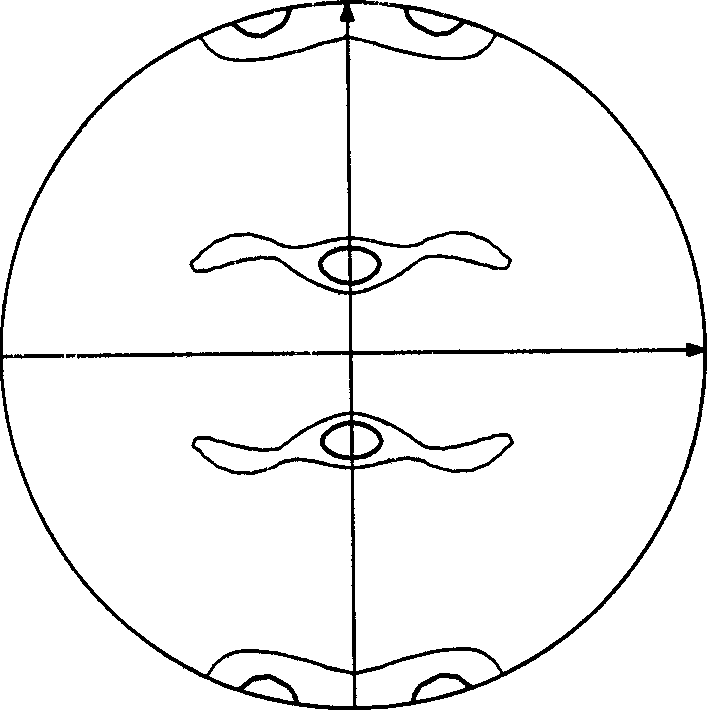

[0013] Use separately figure 1 with figure 2 The method and area shown, the data of two pole figures of {111} and {200} of the domestic deep-drawn aluminum alloy sheet were tested. Its measurement range is: χ angle is π / 6~π / 3, measured in a continuous manner; angle measurement span is π / 2, and the value interval is π / 36. Then the corresponding orientation distribution function is calculated by conventional series expansion method. The result is as image 3 , Figure 4 shown. Depend on Figure 4 It can be seen that in the pole figure detected by this method, the density values greater than 3.0 are detected at the upper and lower ends of the pole figure and the places not far from the upper and lower ends of the pole figure center; low density value. This is the same as image 3 As shown, the density distribution on the polar figure detected by the traditional method is basically consistent, which shows that the method has high precision and is suitable for industri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com