Analysis method for measuring large-grained silicon steel texture

An analytical method, a large-grain technology, applied in the analysis of materials, material analysis using wave/particle radiation, image analysis, etc., can solve problems such as inverse pole diagrams that cannot be used to draw large-grain silicon steel samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

[0014] In a specific embodiment of the present invention: since the surface to be tested of the silicon steel plate must be a flat surface, it meets the requirements of the electron backscattered diffraction test after polishing and other pretreatments. Then cut a piece of large-grained silicon steel of 300mm×30mm to be the area to be tested for the electron backscattered diffraction sample.

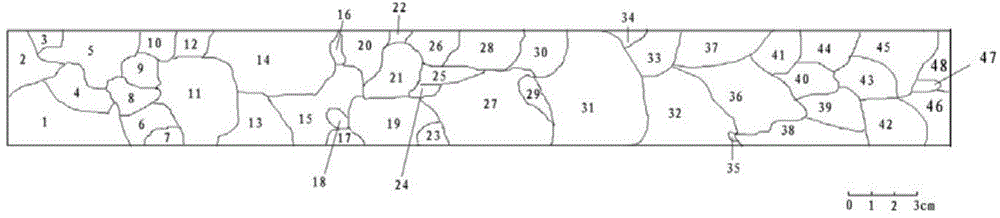

[0015] like figure 1 As shown in , mark the grain boundaries with a marker pen to divide each grain; the marked grains are numbered from 1 to 48 in sequence.

[0016] Take this sample into a photo, and use an image analyzer to measure the area of each grain in the photo: A 1 to A 48 .

[0017] Calculate A 0 the size of:

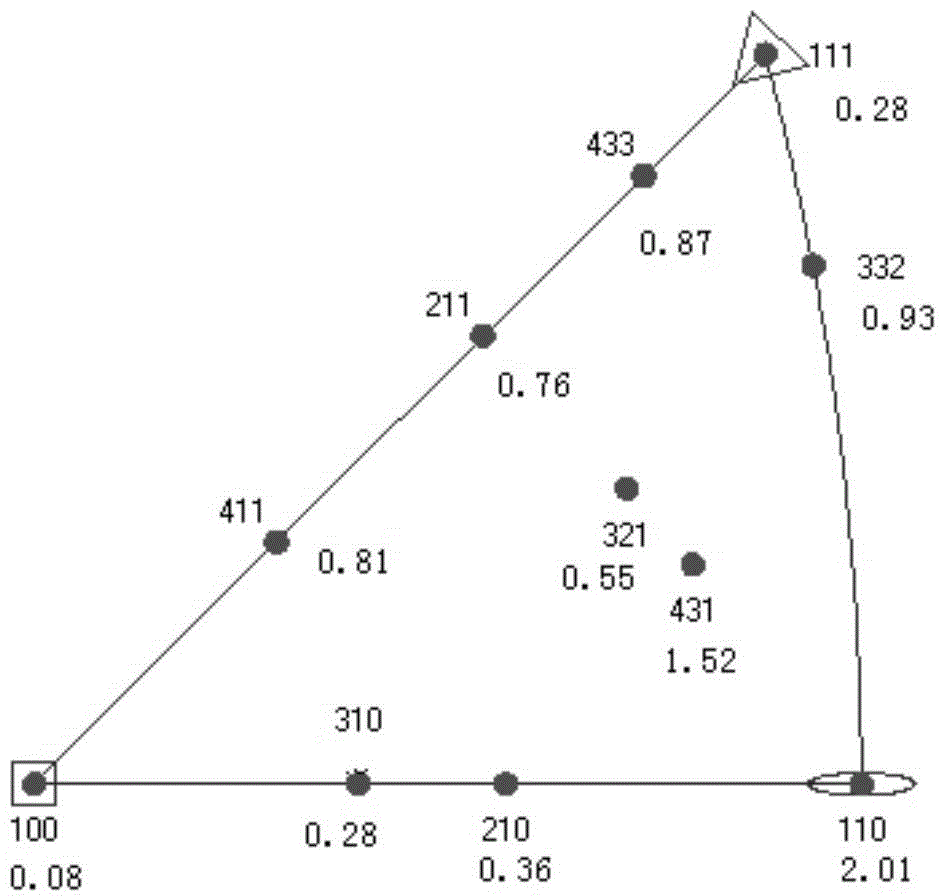

[0018] When surveying and mapping, the {hkl} ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com