Patents

Literature

38 results about "Group 6 element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Group 6, numbered by IUPAC style, is a group of elements in the periodic table. Its members are chromium (Cr), molybdenum (Mo), tungsten (W), and seaborgium (Sg). These are all transition metals and chromium, molybdenum and tungsten are refractory metals. The period 8 elements of group 6 are likely to be either unpenthexium (Uph) or unpentoctium (Upo). This may not be possible; drip instability may imply that the periodic table ends around unbihexium. Neither unpenthexium nor unpentoctium have been synthesized, and it is unlikely that this will happen in the near future.

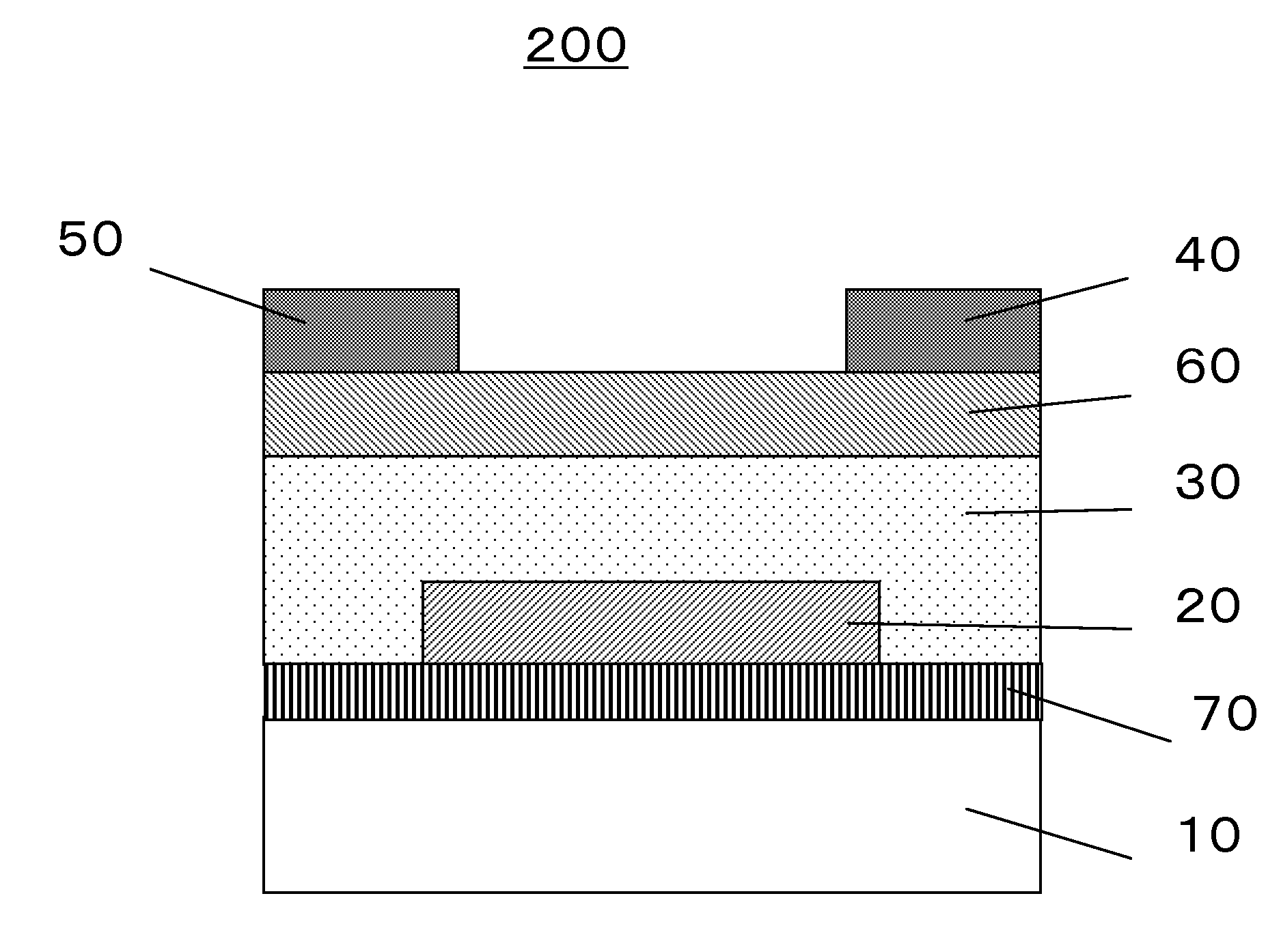

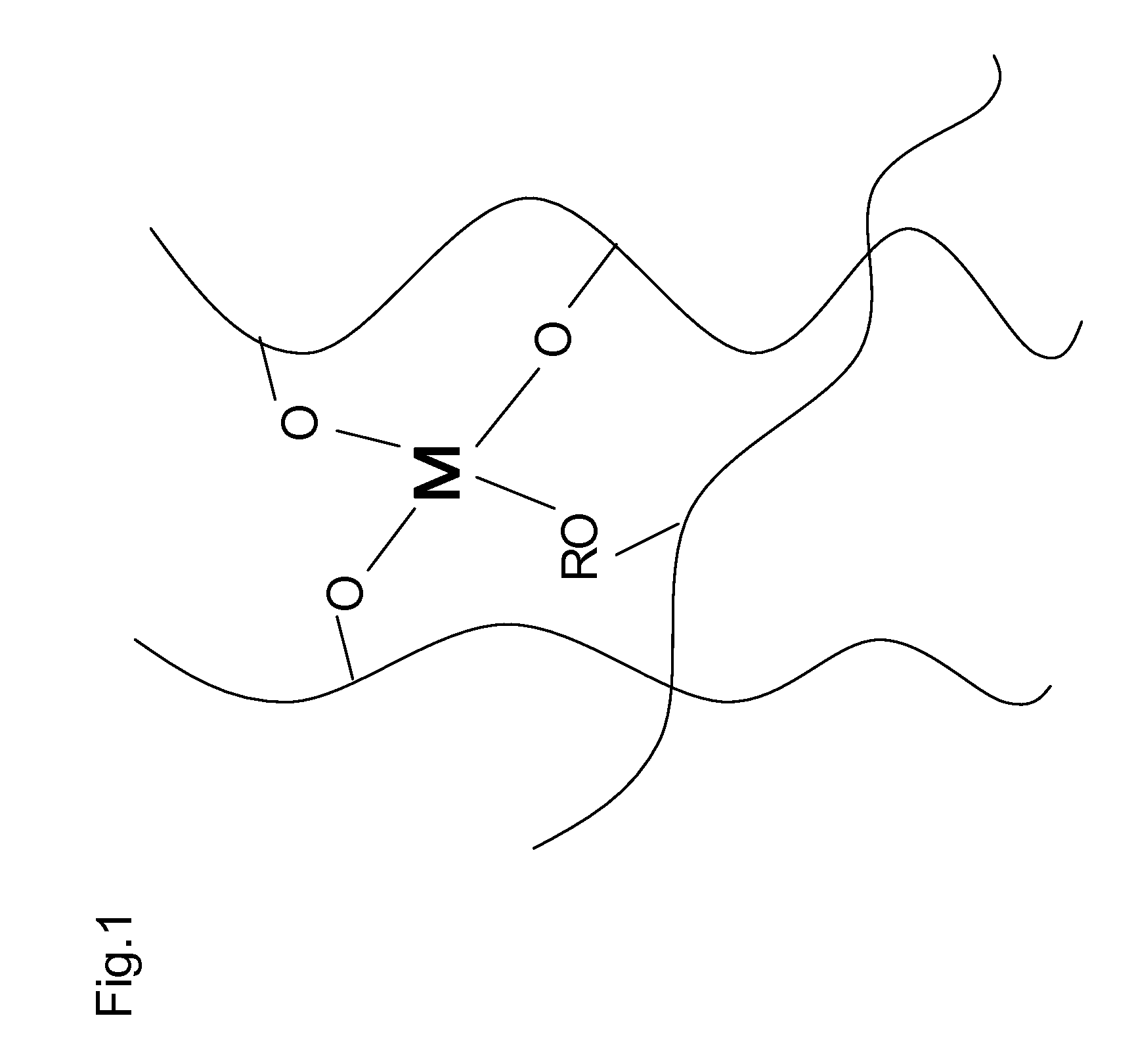

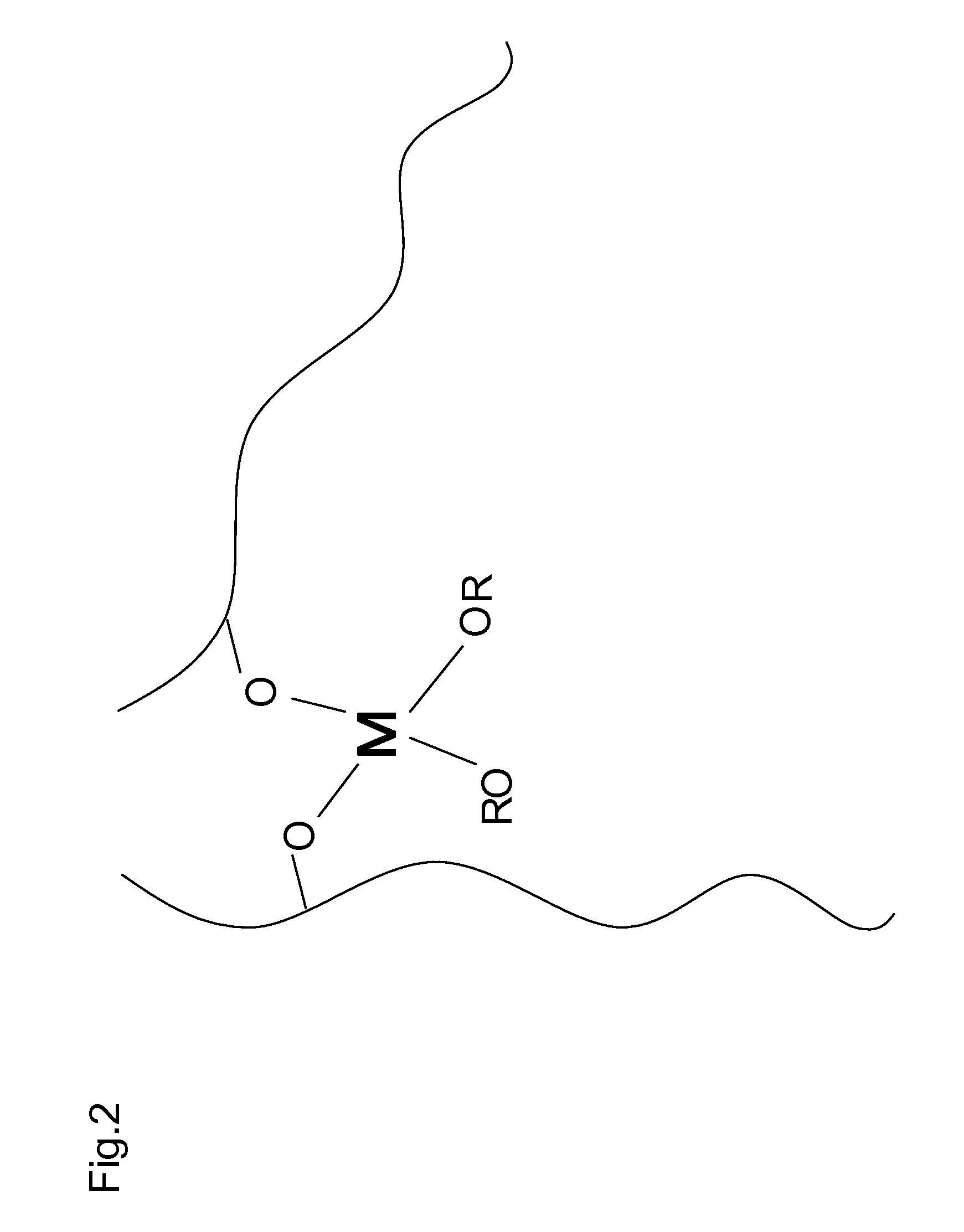

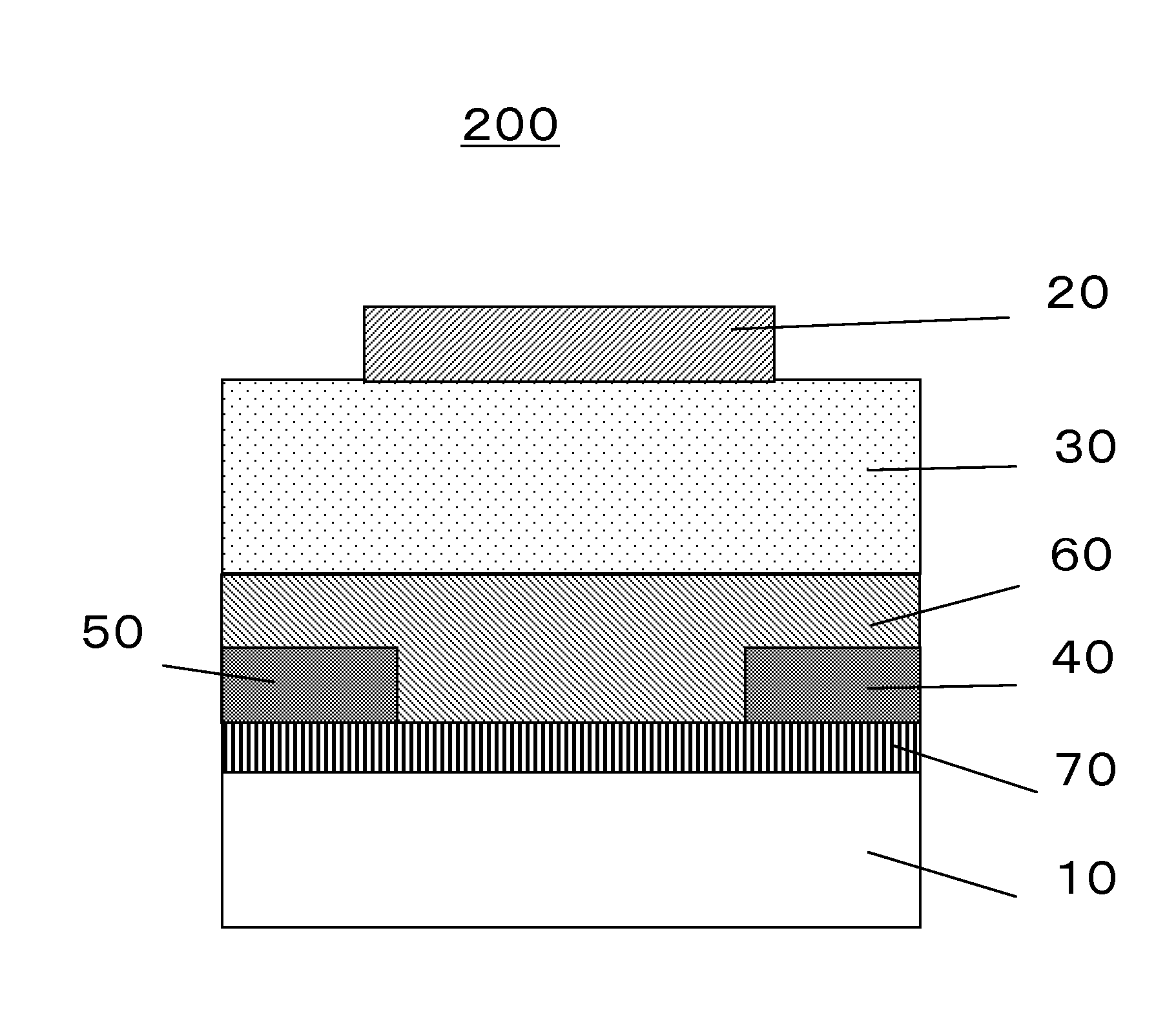

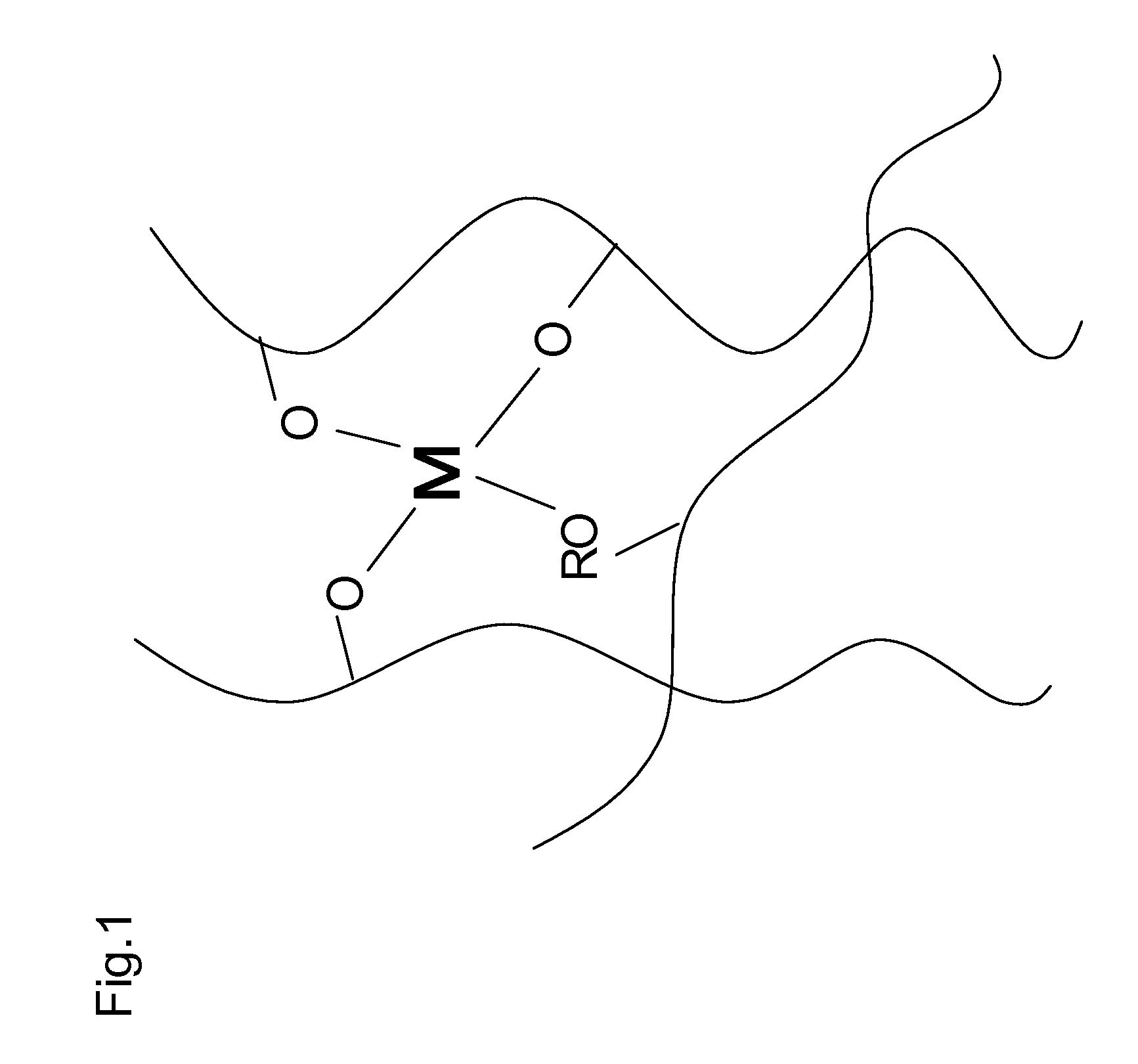

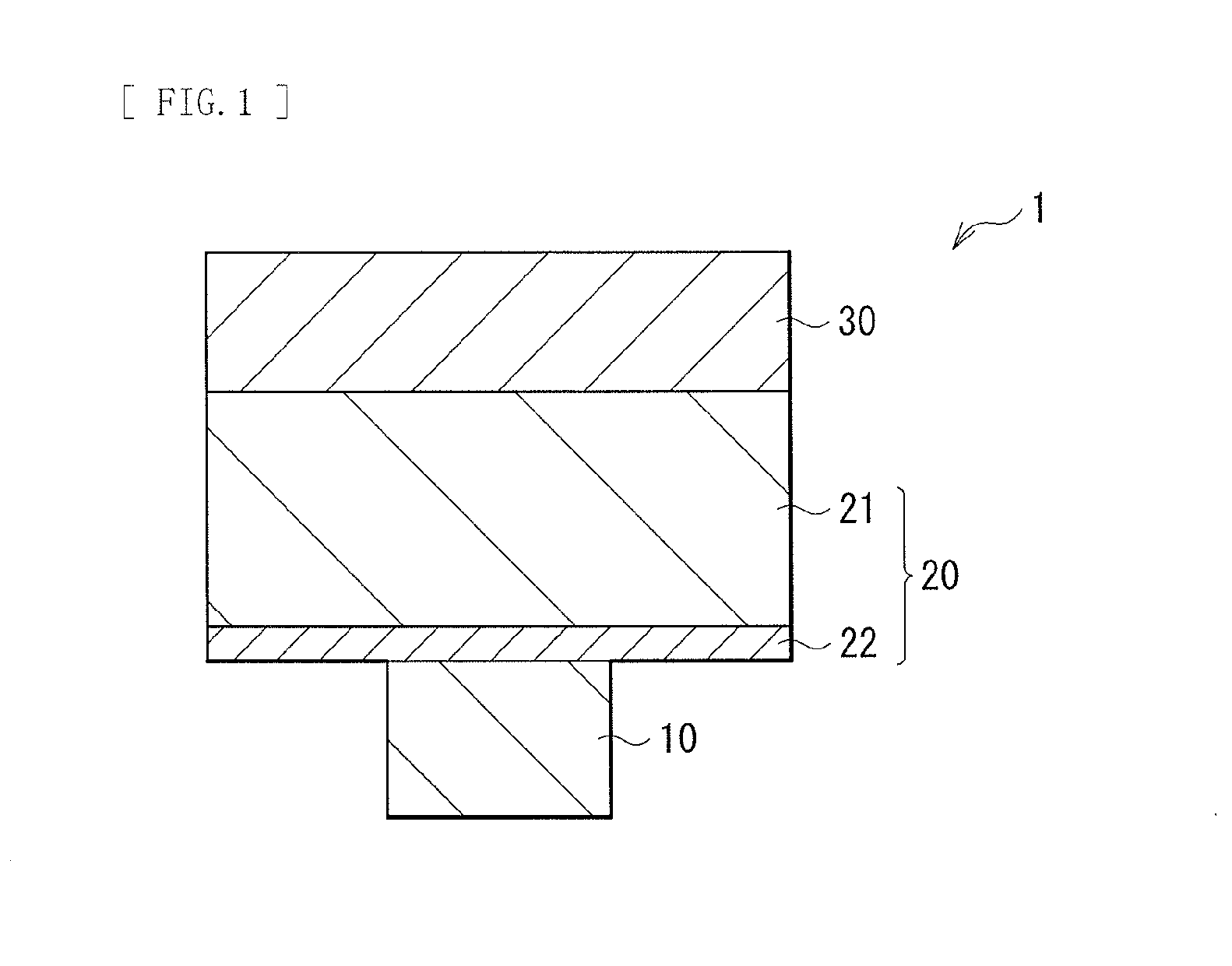

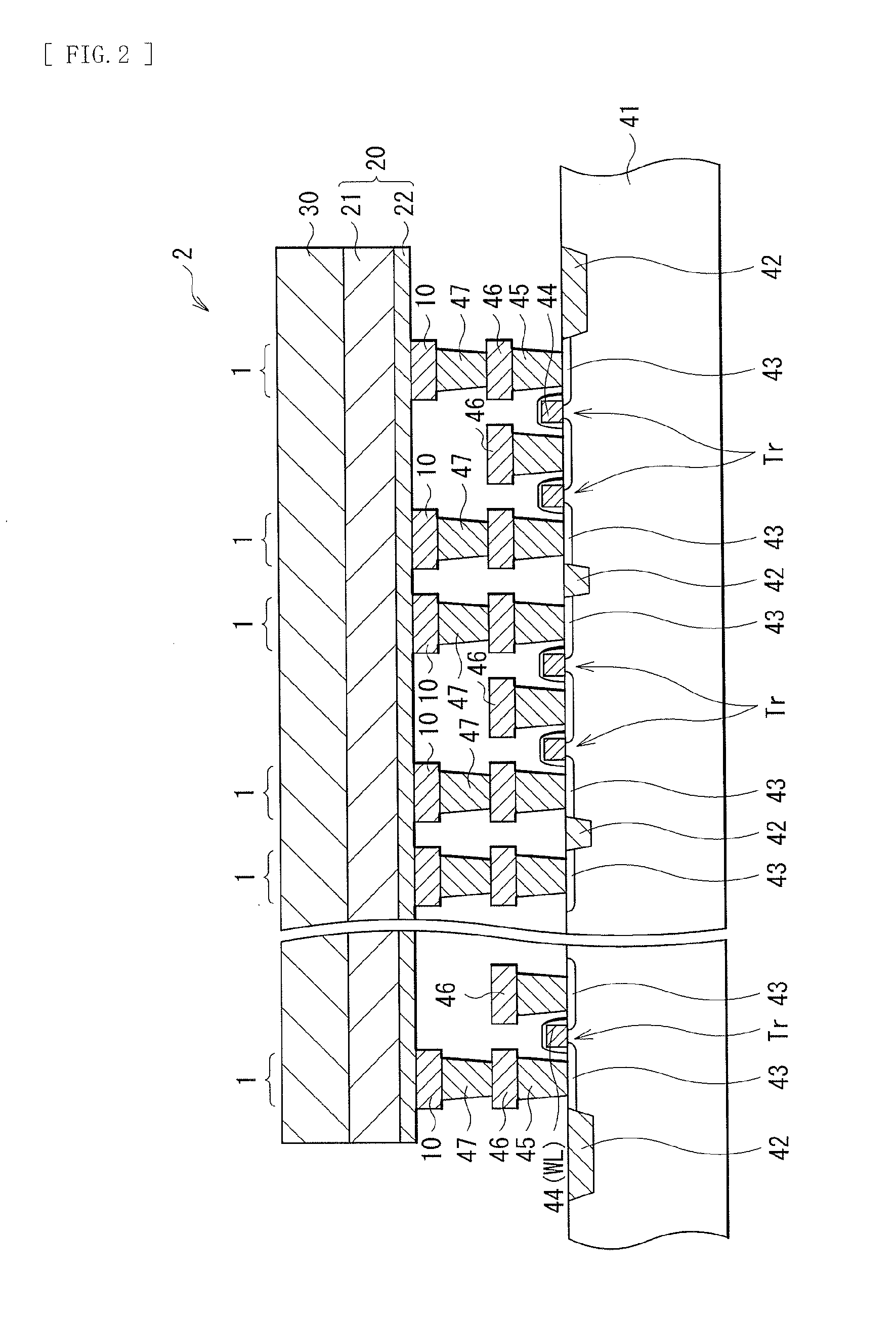

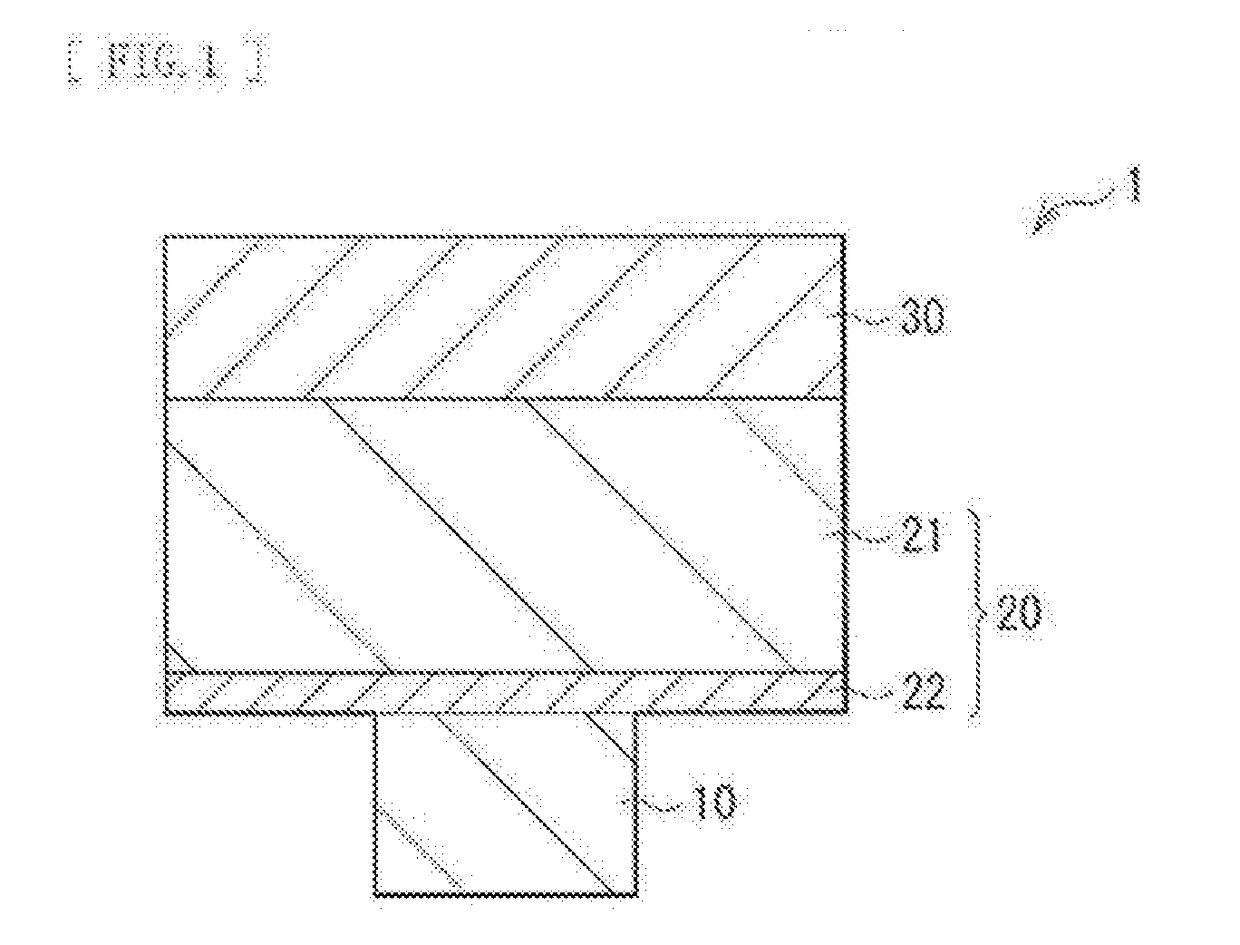

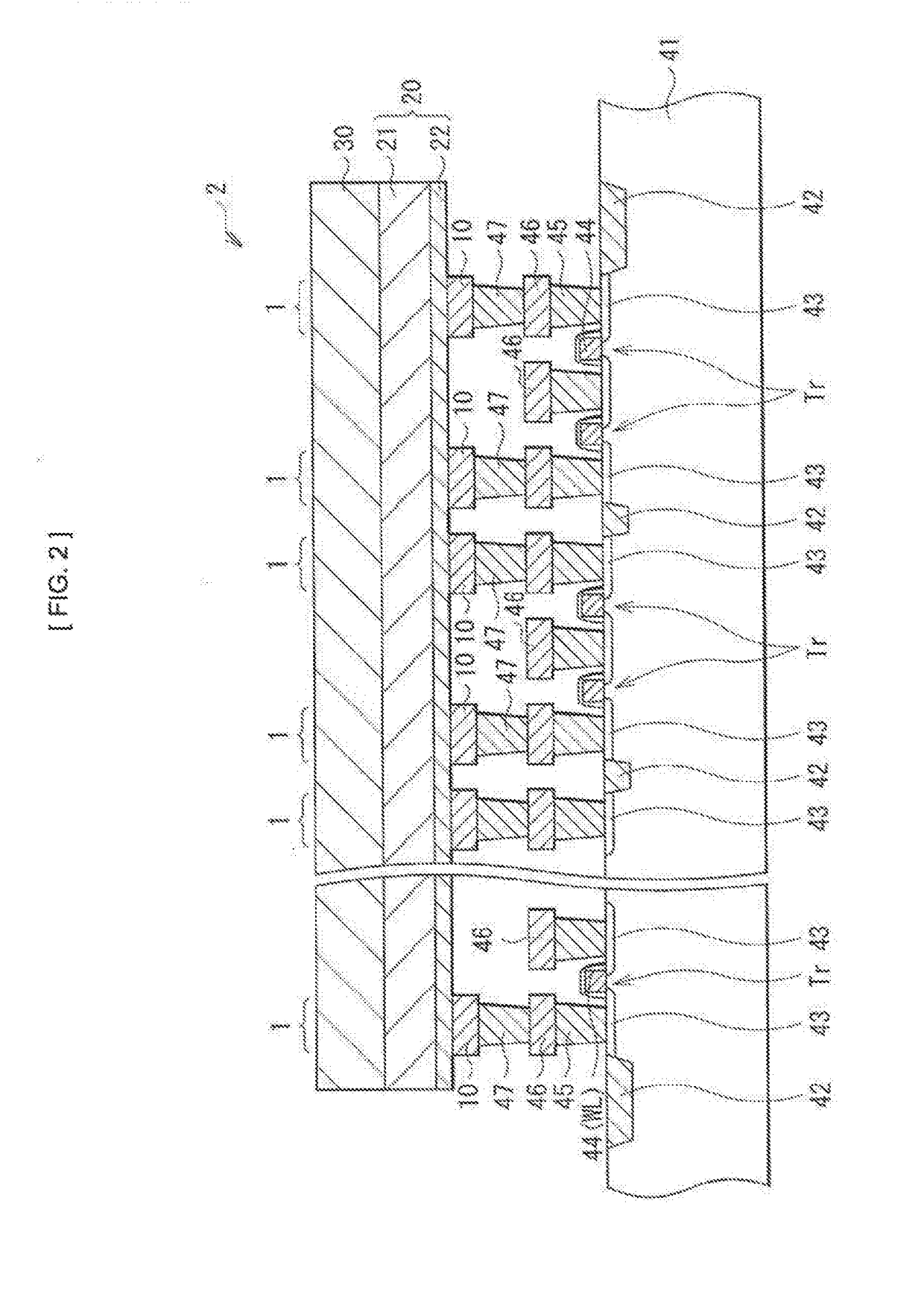

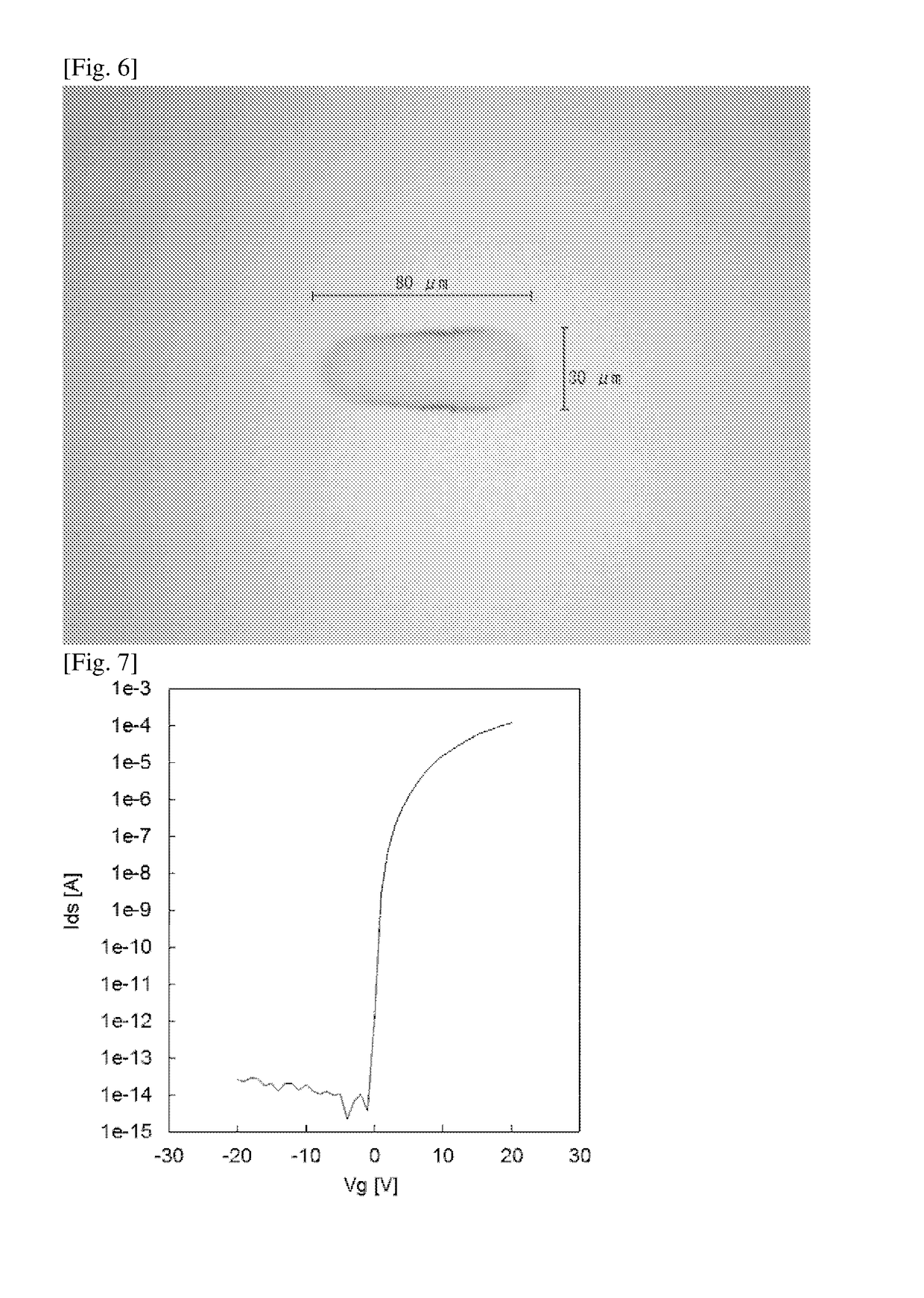

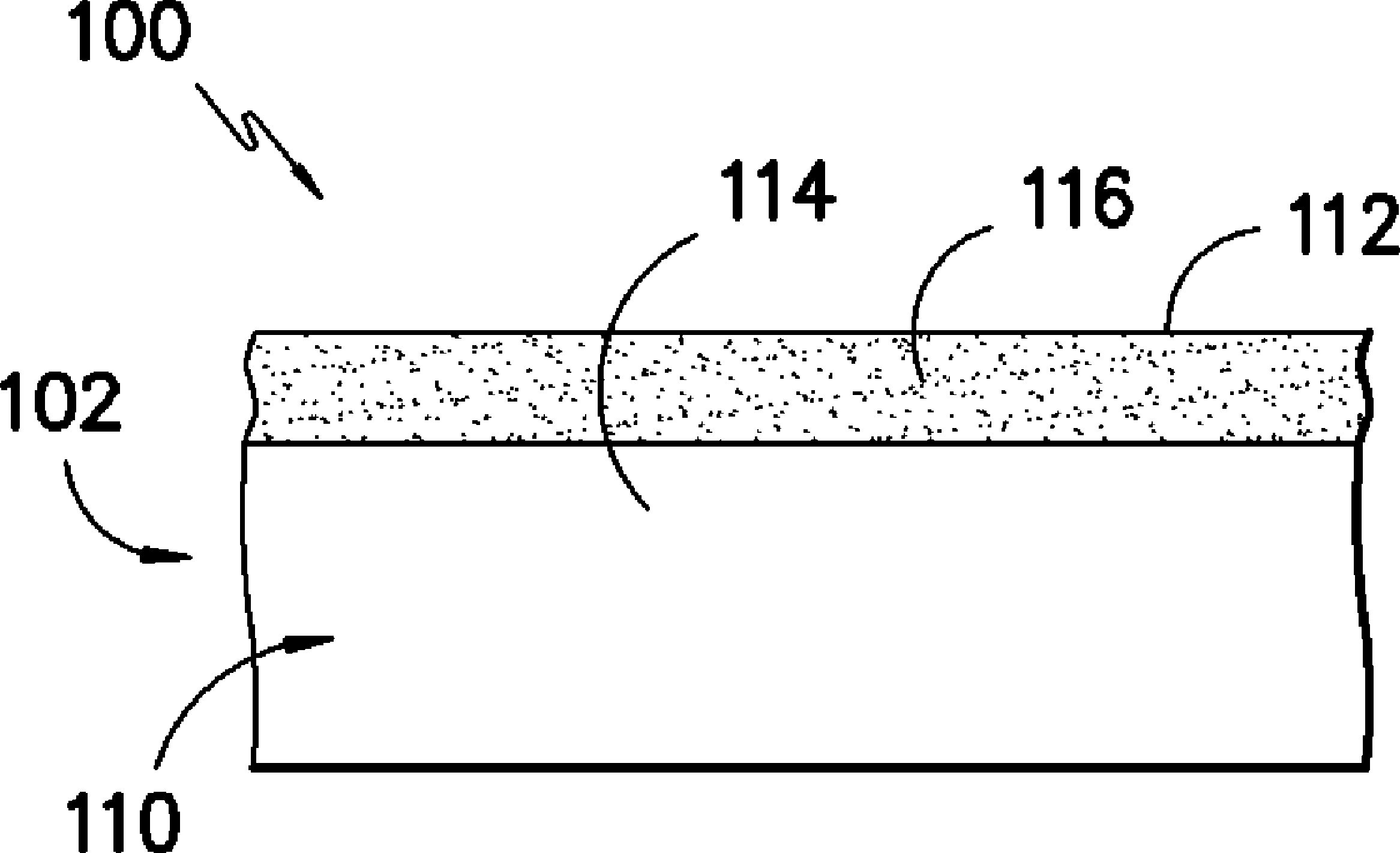

Insulating Thin Film, Formation Solution For Insulating Thin Film, Field-Effect Transistor, Method For Manufacturing The Same And Image Display Unit

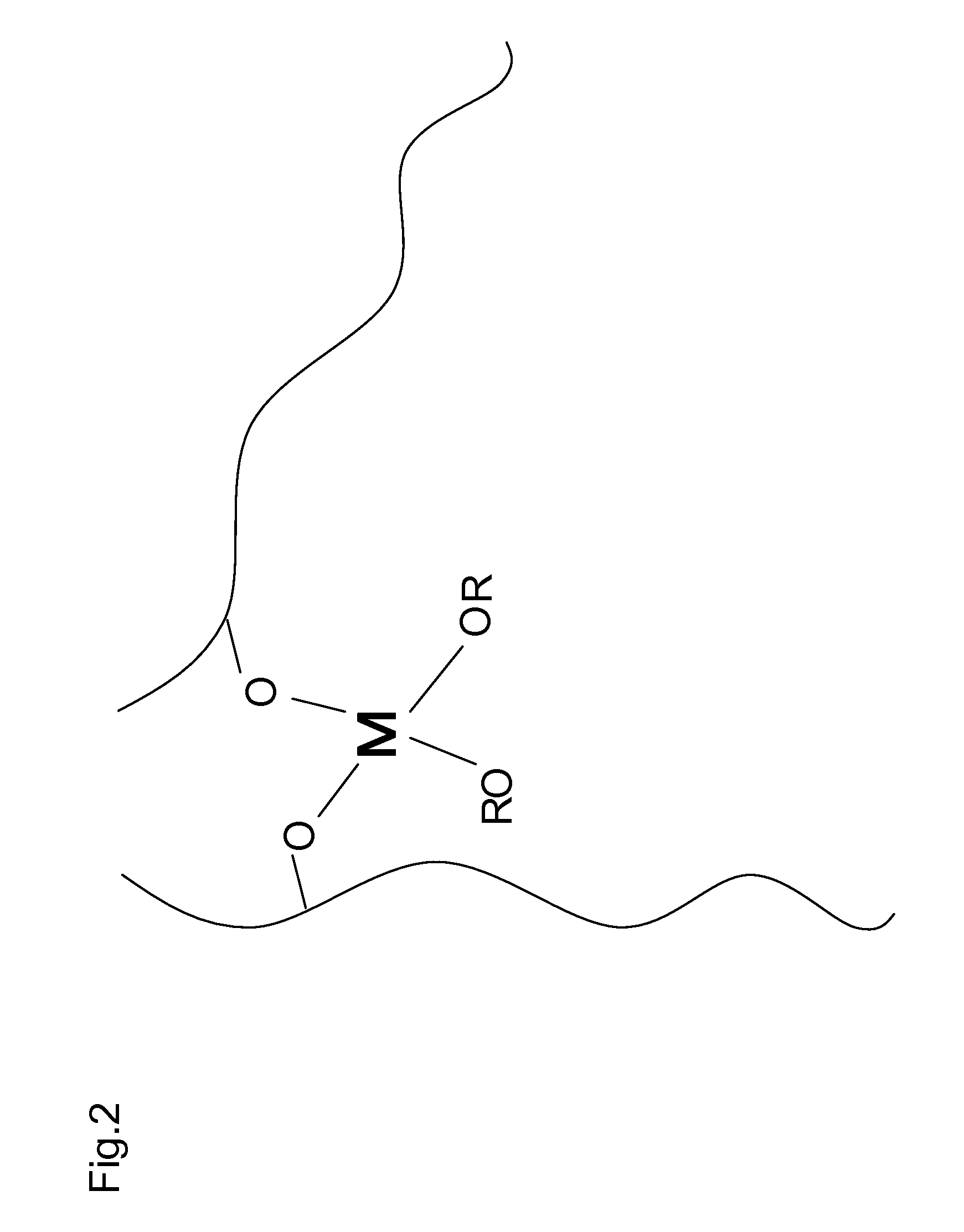

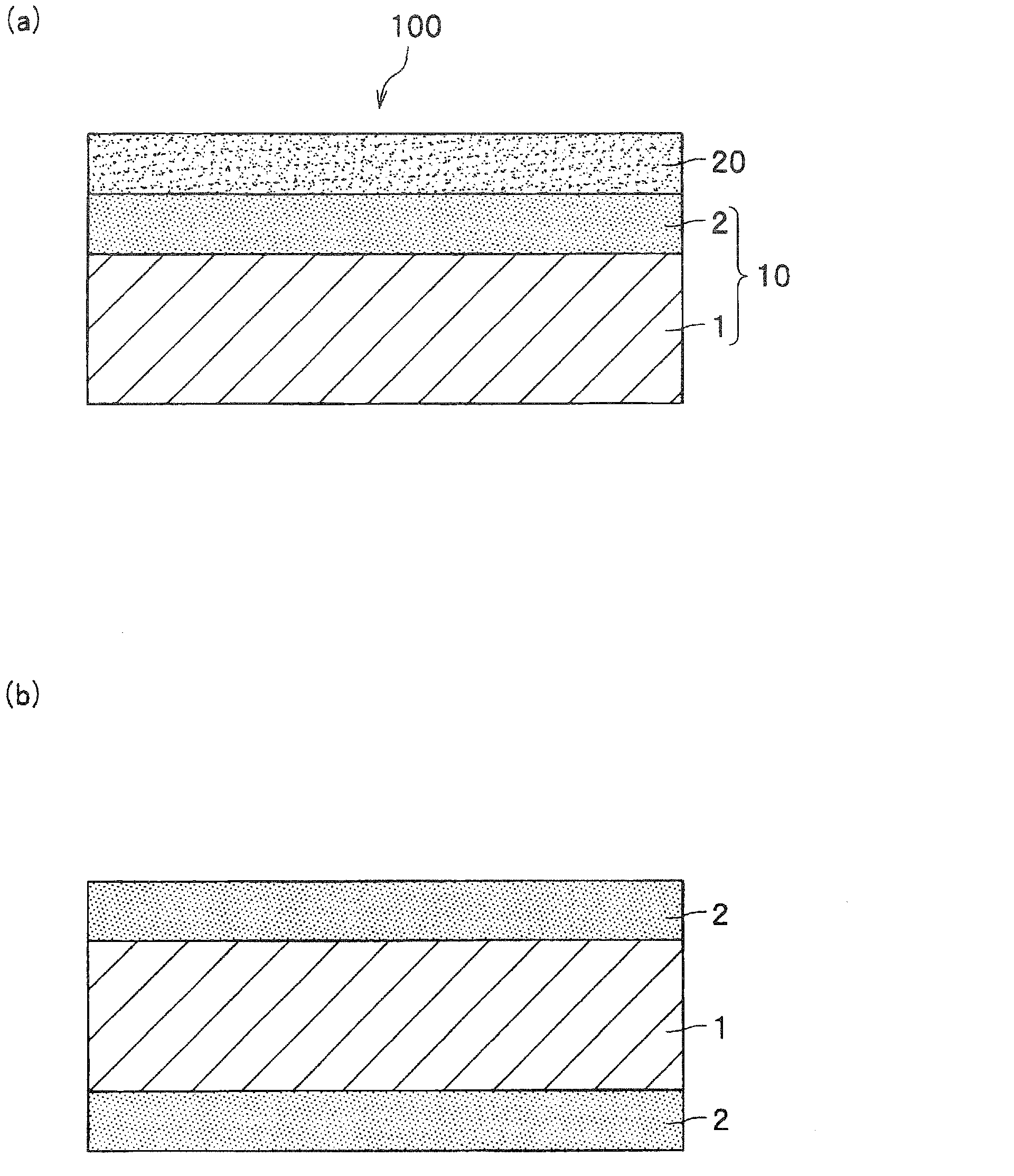

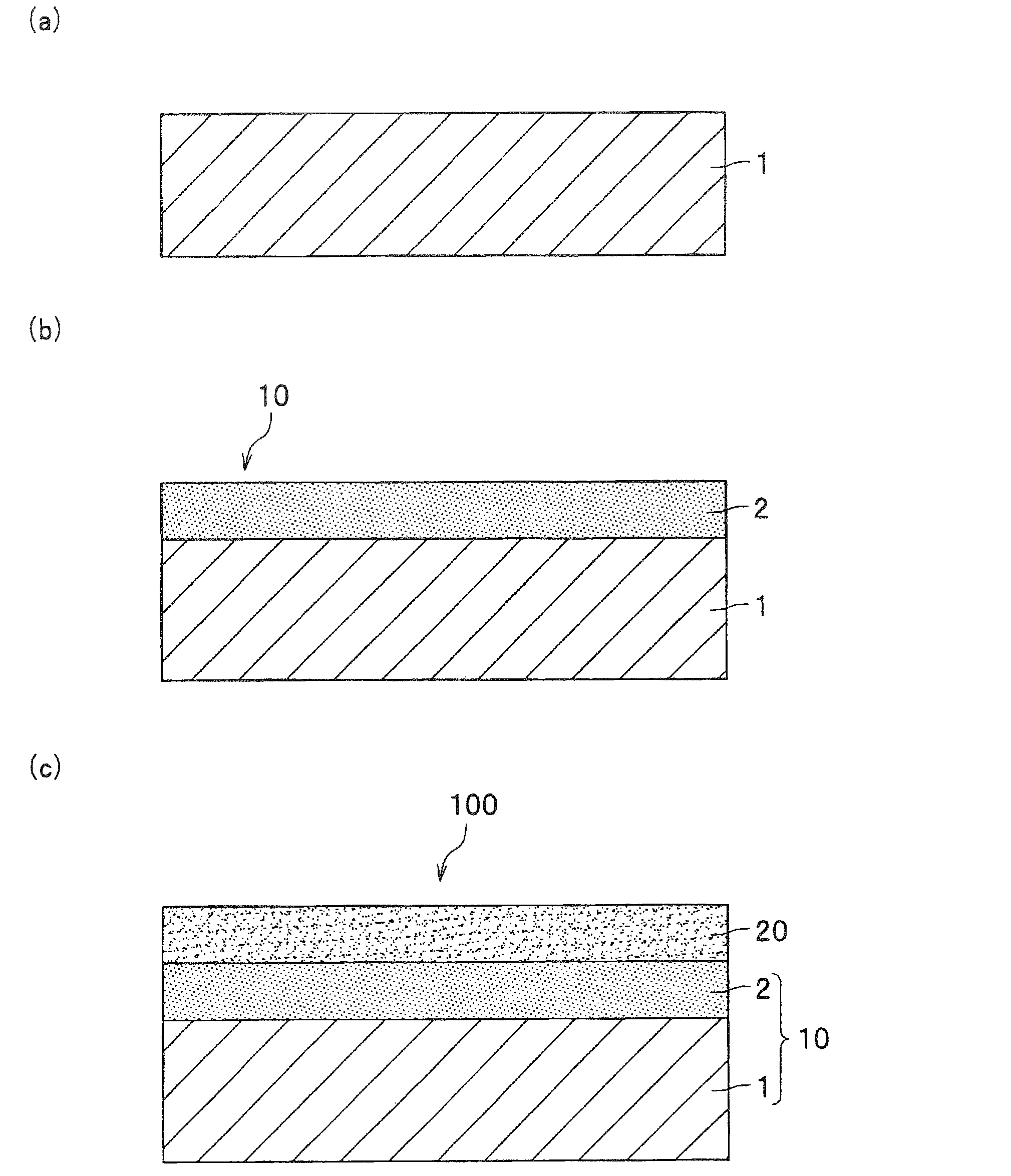

One embodiment of the present invention is an insulating thin film having a polymer compound, a metallic atom bonded to the polymer compound through an oxide atom and selected from a group 4 element, a group 5 element, a group 6 element, a group 13 element, zinc or tin, and an organic molecule bonded to the metallic atom through the oxide atom or a nitrogen atom.

Owner:TOPPAN PRINTING CO LTD

Catalyst for production of acetic acid and ethyl acetate, process for its production and process for production of acetic acid and ethyl acetate using it

InactiveUS6552220B1Low carbon dioxide selectivityImprove catalytic performanceOxygen-containing compound preparationOrganic compound preparationAcetic acidGroup 12 element

An acetic acid production catalyst that contains (b) at least one element selected from the group consisting of Group 14 elements, Group 15 elements and Group 16 elements of the Periodic Table and / or (c) at least one element selected from the group consisting of Group 6 elements, Group 7 elements, Group 8 elements, Group 9 elements, Group 10 elements, Group 11 elements and Group 12 elements of the Periodic Table, added to a palladium-loaded catalyst, as well as an acetic acid and ethyl acetate production catalyst that contains (b) at least one compound selected from the group consisting of inorganic acids and salts thereof and / or (c) at least one element selected from the group consisting of Group 14 elements, Group 15 elements and Group 16 elements of the Periodic Table and / or (d) at least one element selected from the group consisting of Group 6 elements, Group 7 elements, Group 8 elements, Group 9 elements, Group 10 elements, Group 11 elements and Group 12 elements of the Periodic Table, added to palladium.

Owner:SHOWA DENKO KK

Hydrotreating catalyst, method for producing the catalyst, and hydrotreating process for hydrocarbon oil using the catalyst

InactiveUS20170073592A1Efficient removalOrganic-compounds/hydrides/coordination-complexes catalystsHeterogenous catalyst chemical elementsSilicon dioxideGroup 6 element

To provide a catalyst having hydrotreatment (hydrogenation, desulfurization and denitrification) performance that is equal to or superior to the prior art, as a hydrotreating catalyst for hydrocarbon oils, and a hydrotreating process for hydrocarbon oils using the catalyst. The catalyst comprises 10 to 40 mass % of at least one element of Group 6 of the Periodic Table, 0.5 to 15 mass % of at least one element of Groups 8 to 10 of the Periodic Table based on the oxide catalysts, and a 0.05- to 3-fold amount of an organic additive with respect to the total number of moles of the elements of Group 6 and Groups 8 to 10 of the Periodic Table, added to an inorganic porous support composed mainly of silica-alumina that comprises an oxide of a metal of Group 2 of the Periodic Table.

Owner:NIPPON KETJEN CO LTD

Method for producing hydrotreated oil and method for producing catalytic cracked oil

InactiveUS20180016505A1Efficiently obtainedTreatment with hydrotreatment processesRefining to eliminate hetero atomsPore diameterGroup 6 element

There is provided a method for producing hydrotreated oil comprising: a step of passing heavy hydrocarbon oil through a reactor filled with a hydrotreating catalyst to obtain hydrotreated oil, wherein the hydrotreating catalyst contains phosphorus, an iron group element, and a group 6 element; the ratio C2 / C1 of a content C2 of the iron group element to a content C1 of phosphorus in the hydrotreating catalyst is less than 0.60 in a molar ratio; and the average pore diameter of the hydrotreating catalyst is larger than 7.5 nm and smaller than 9.5 nm.

Owner:JXTG NIPPON OIL & ENERGY CORPORATION

Fuel cell and electrocatalyst

An embodiment of the invention provides an electrocatalyst, including a four-element catalyst having a formula of XYZP, wherein X is Pt or Pd, Y and Z are different elements selected from Group 6, Group 8, Group 9, or Group 11 elements, and P is phosphorous, wherein Group 6 elements include Cr, Mo, or W, Group 8 elements include Fe, Ru, or Os, Group 9 elements include Co, Rh, or Ir, and Group 11 elements include Cu, Ag, or Au.

Owner:IND TECH RES INST

Olefin production process

ActiveUS20120010453A1High selectivityMolecular sieve catalystsHeterogenous catalyst chemical elementsHeteropoly acidIon exchange

A novel olefin production process is provided which can be established as an industrial and practical process capable of producing olefins by directly reacting a ketone and hydrogen in a single reaction step. In particular, a novel olefin production process is provided in which propylene is obtained with high selectivity by directly reacting acetone and hydrogen.The olefin production process according to the present invention includes reacting a ketone and hydrogen in the presence of at least one dehydration catalyst and a silver-containing catalyst, and the at least one dehydration catalyst is selected from metal oxide catalysts containing a Group 6 element, zeolites, aluminas and heteropoly acid salts in which part or all the protons in heteropoly acids are exchanged with metal cations.

Owner:MITSUI CHEM INC

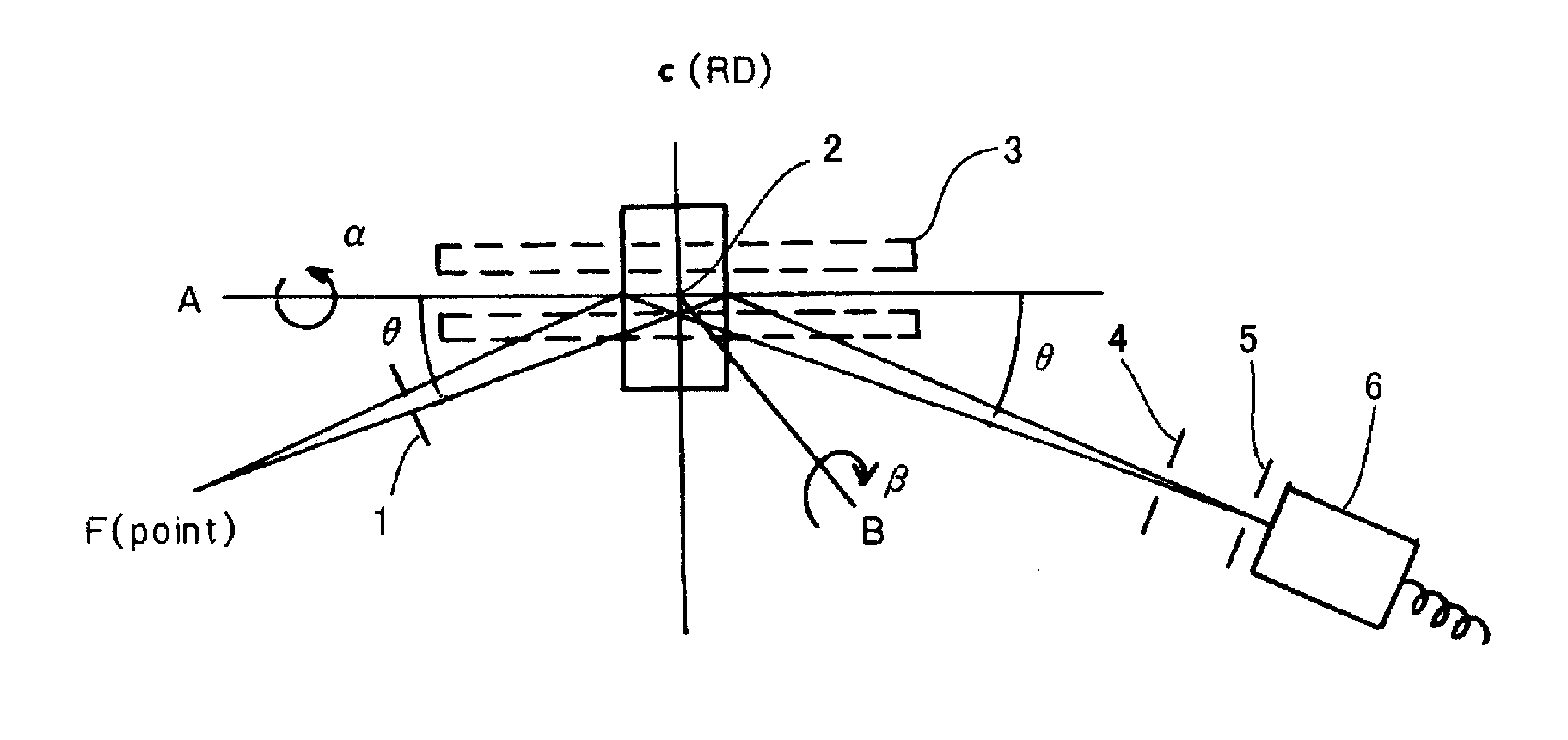

Coated Member

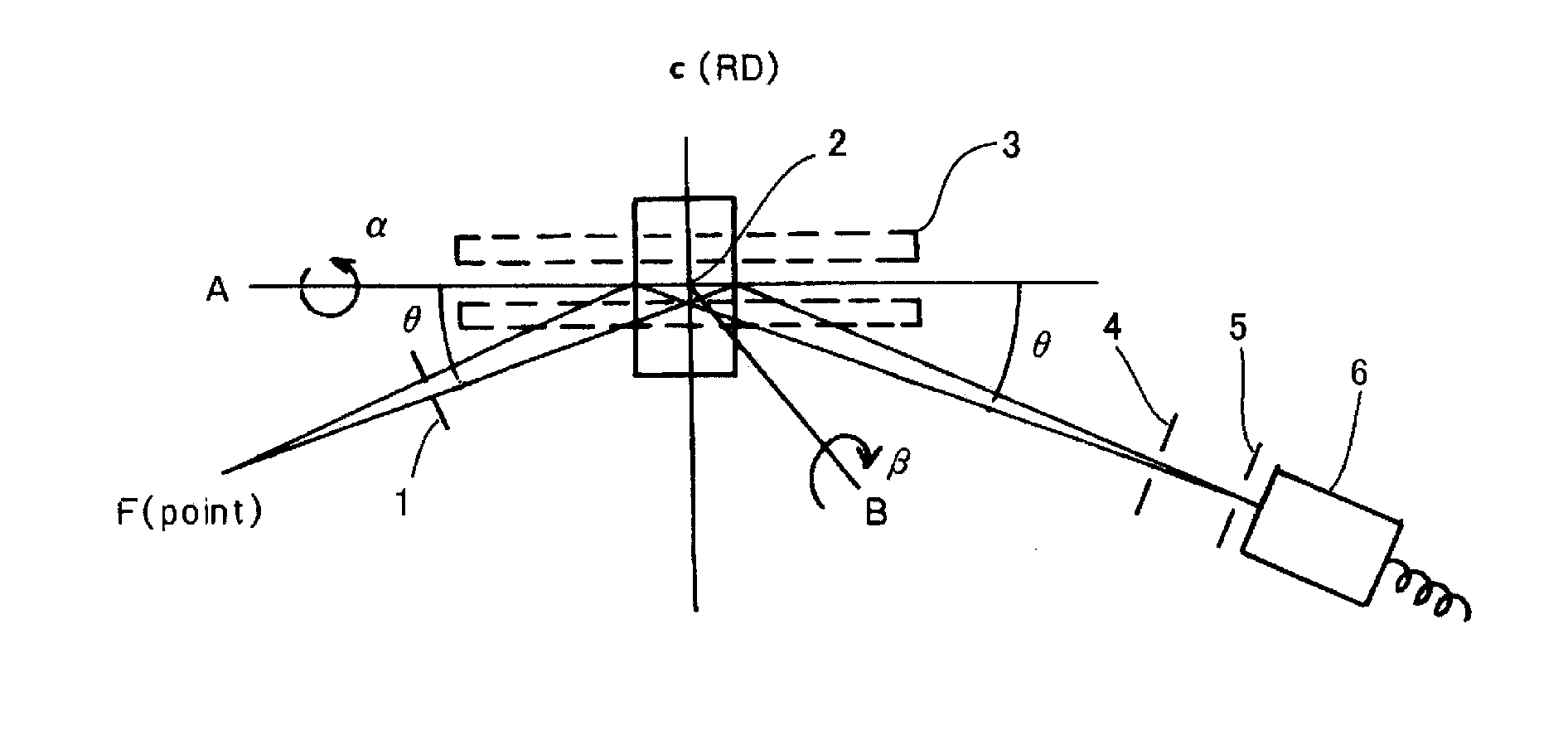

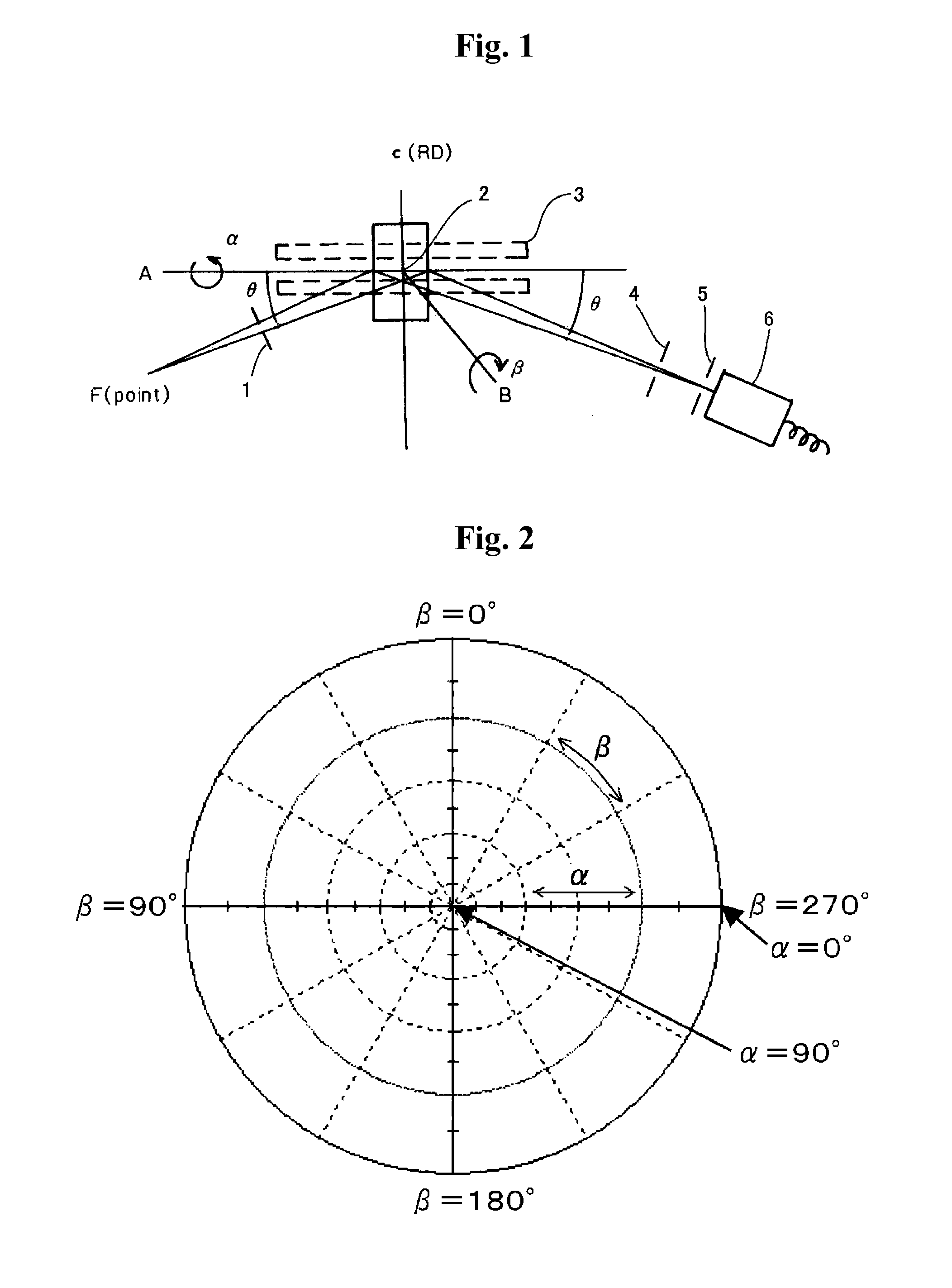

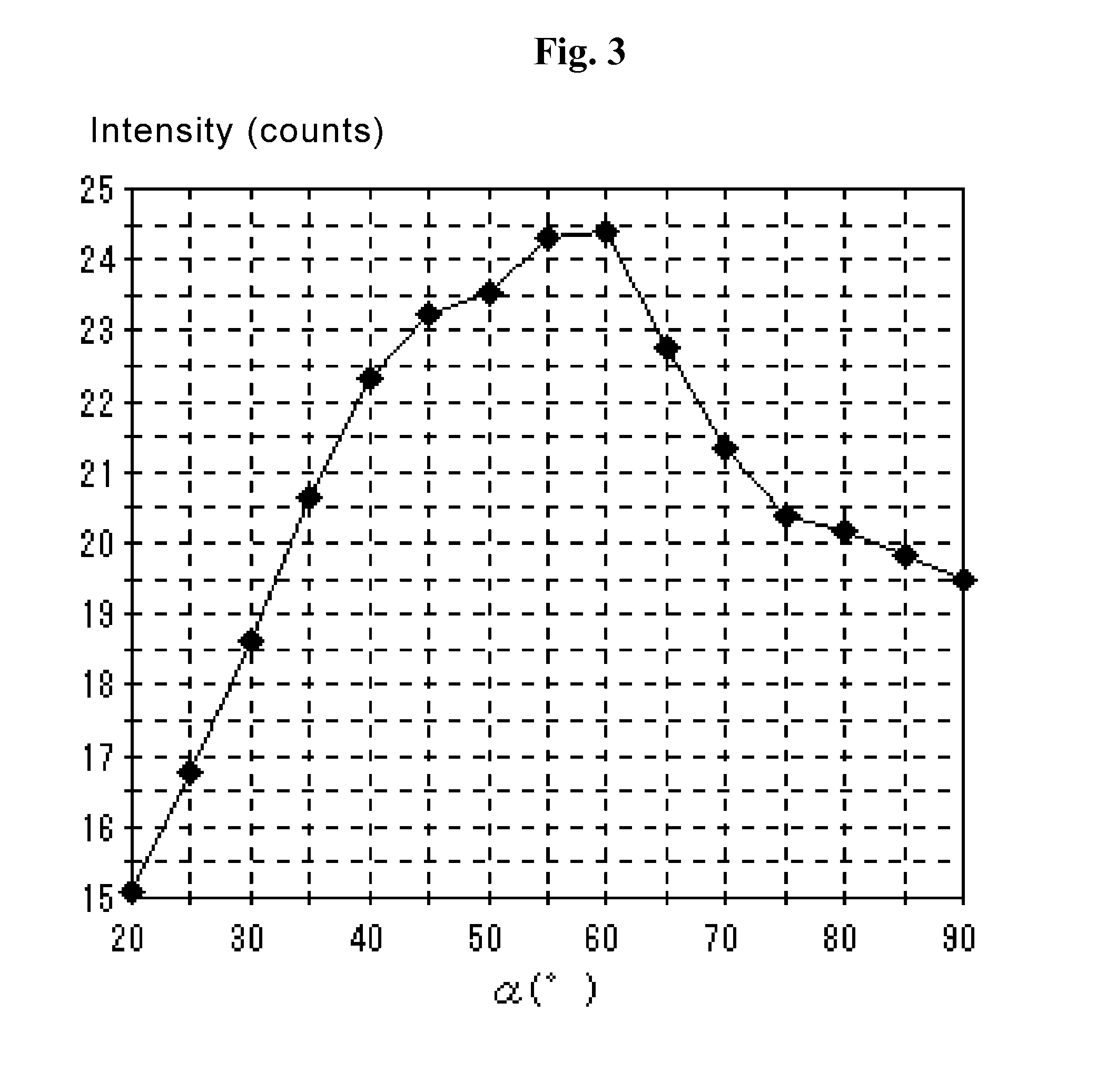

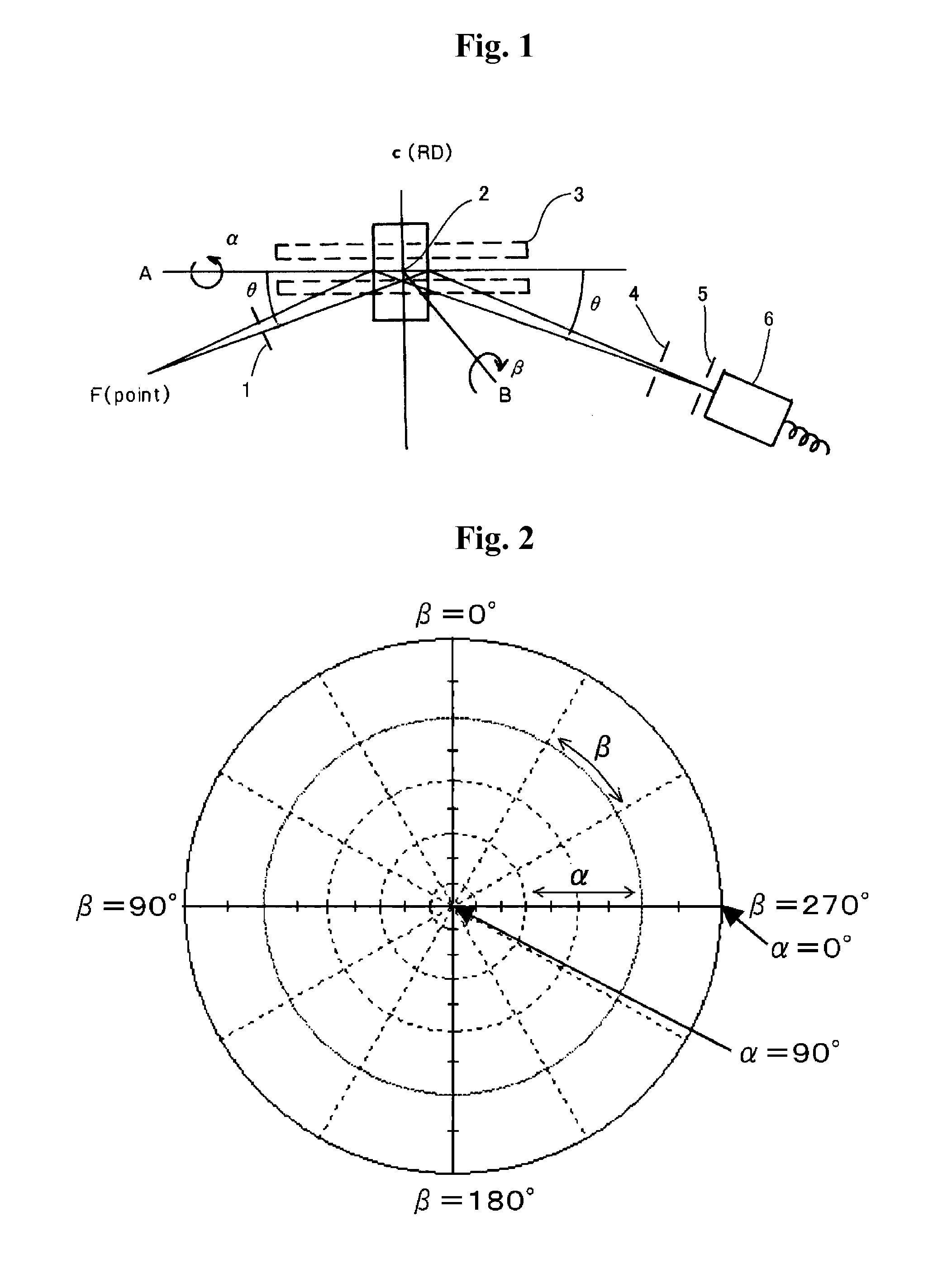

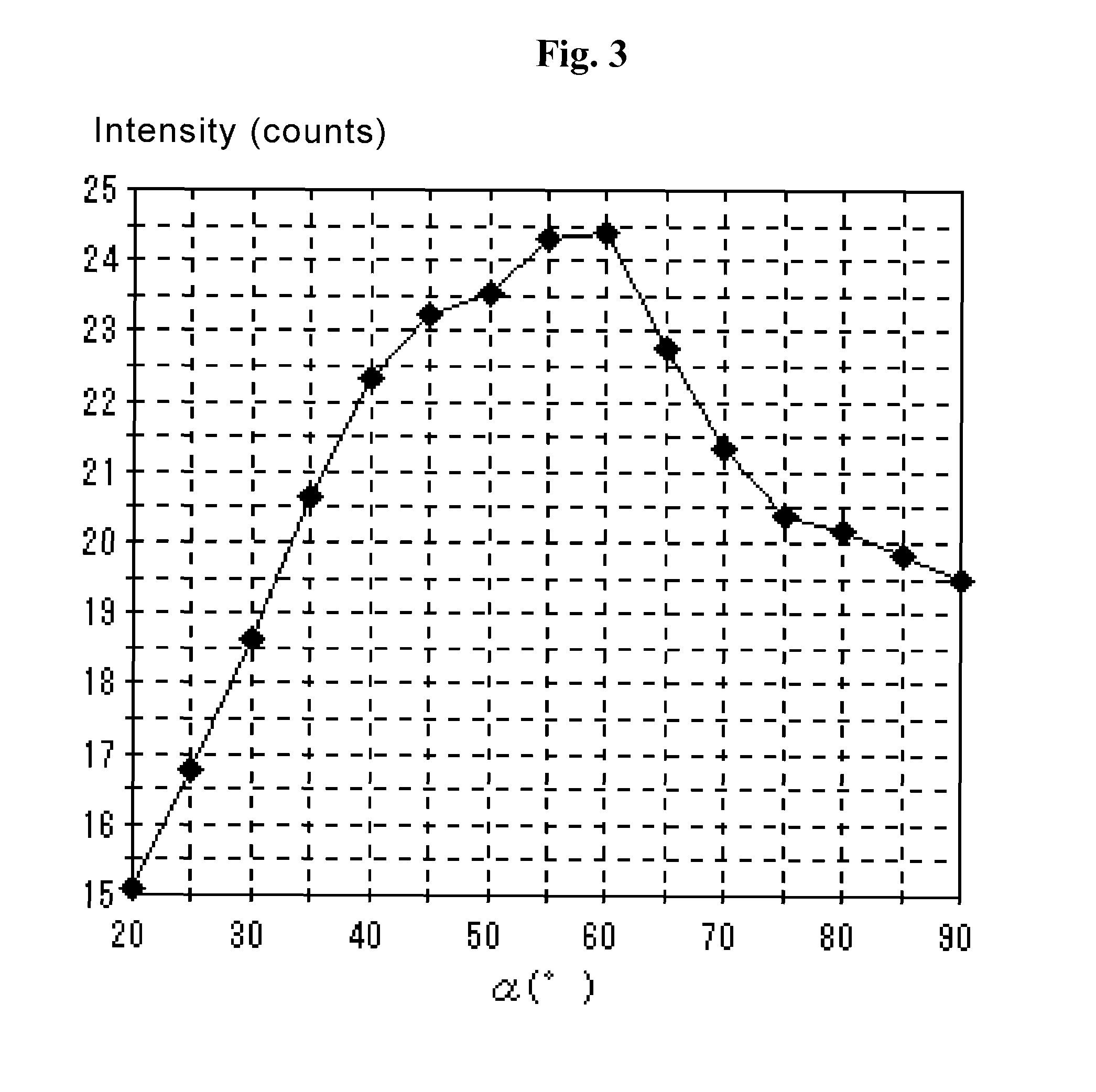

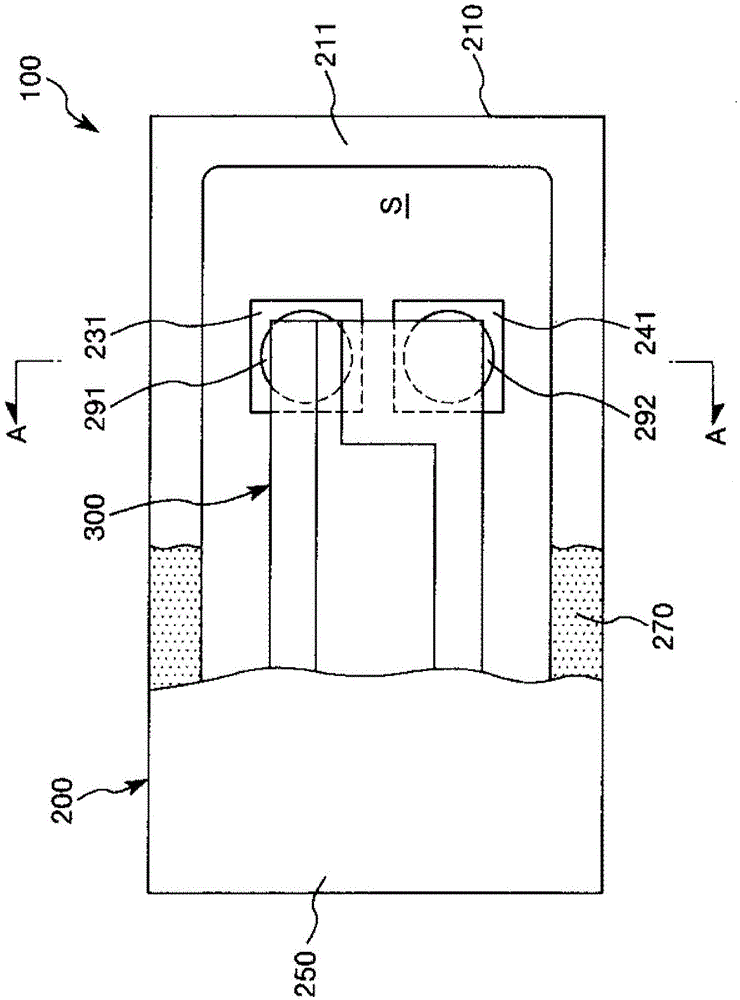

ActiveUS20120128971A1Improve adhesionExcellent in wear resistance and fracture resistance and oxidation resistancePigmenting treatmentOther chemical processesX-rayGroup 6 element

A coated member includes a base material and a coating film formed on the surface thereof. At least one layer in the coating film is a hard film of a cubic metal compound including at least one element selected from the group consisting of the group 4 elements (Ti, Zr, Hf, etc.), group 5 elements (V, Nb, Ta, etc.) and group 6 elements (Cr, Mo, W, etc.) of the periodic table, Al, Si, B, Y and Mn together with at least one element selected from the group consisting of C, N and O. In the pole figure for the face (111) of the hard film, the X-ray intensity distribution in the α-axis shows the maximum intensity in the α-angle range of 50-65°. In the pole figure for the face (200), the X-ray intensity distribution in the α-axis shows the maximum intensity in the α-angle range of 60-80°.

Owner:TUNGALOY CORP

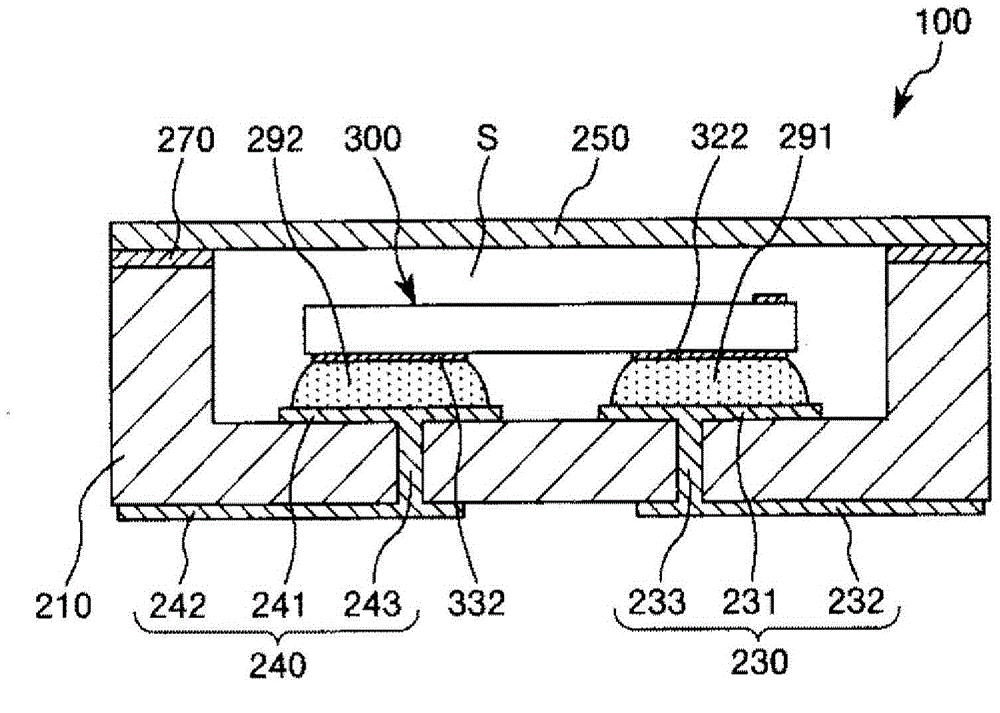

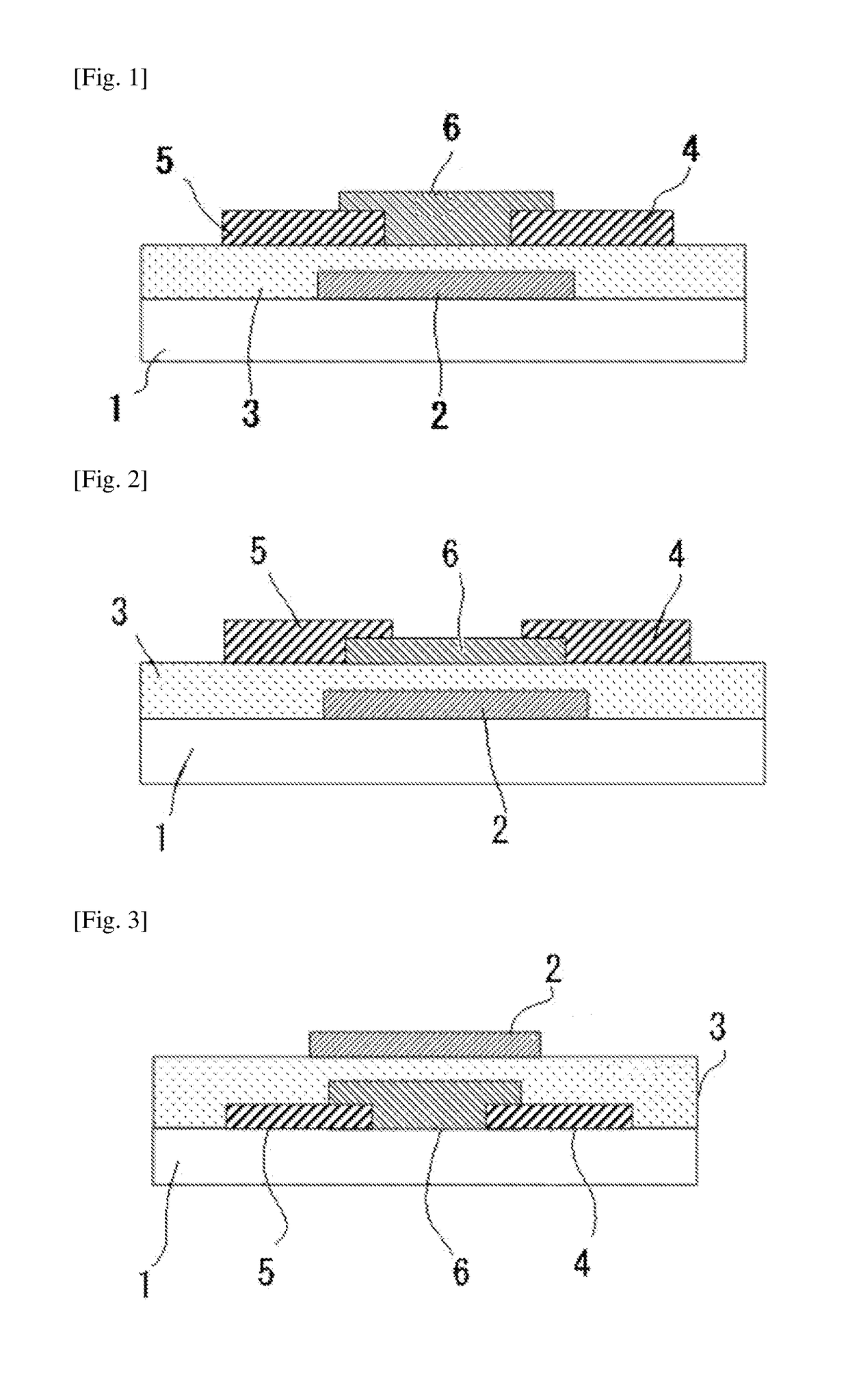

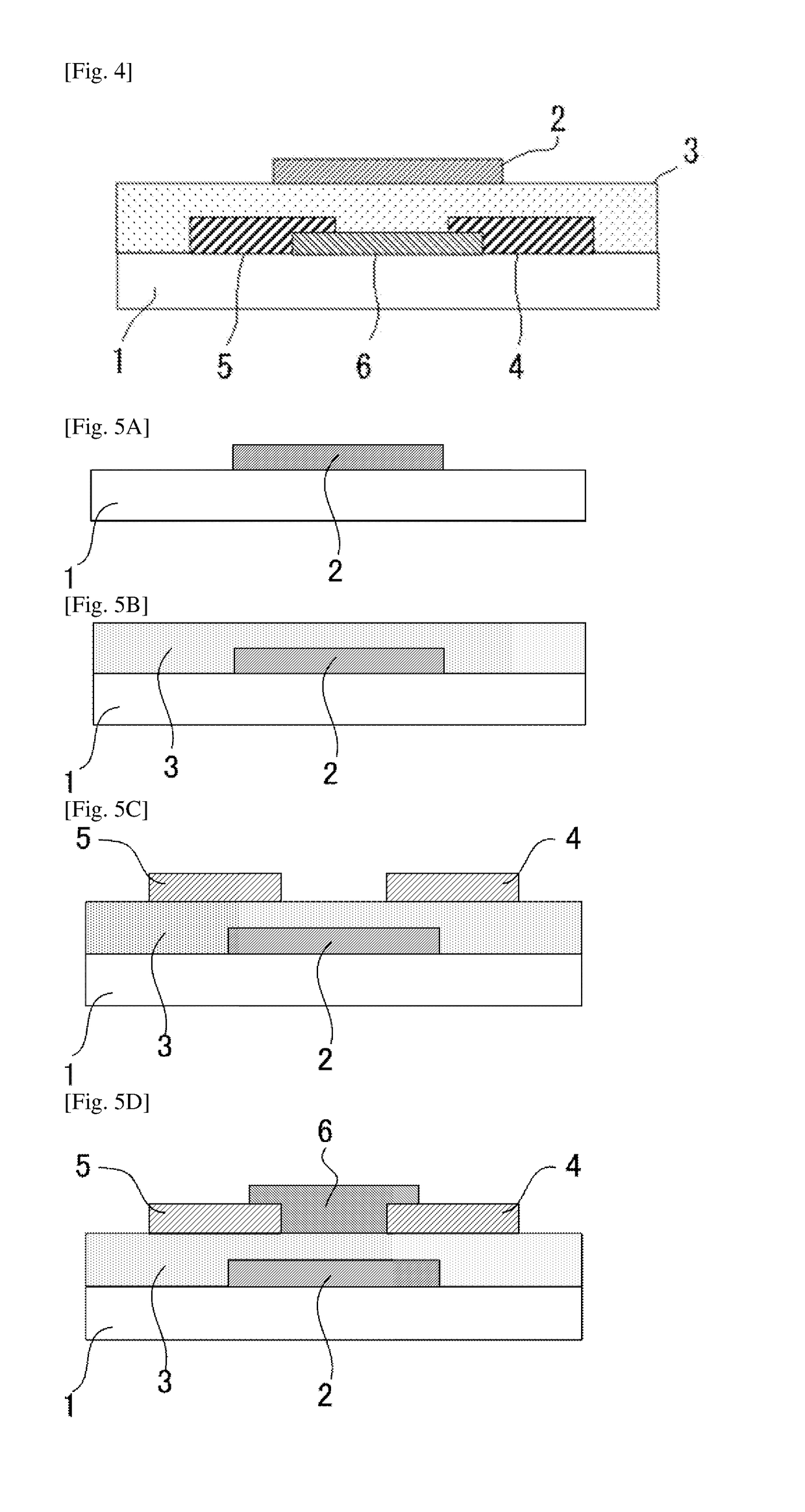

Circuit board, method for manufacturing circuit board, electronic device, electronic apparatus, and moving object

InactiveUS20150070855A1Improve adhesionImprove reliabilitySolid-state devicesPrinted circuit secondary treatmentElectrical conductorGroup 6 element

A circuit board includes a ceramics substrate composed of ceramics and a conductor portion provided on the ceramics substrate. The conductor portion is composed of a stacked body including, in order from the ceramics substrate side, an under layer that contains a Group 6 element and a glass material, and a metal layer that contains a low-melting-point metal. A portion of the low-melting-point metal constituting the metal layer migrates to the under layer.

Owner:SEIKO EPSON CORP

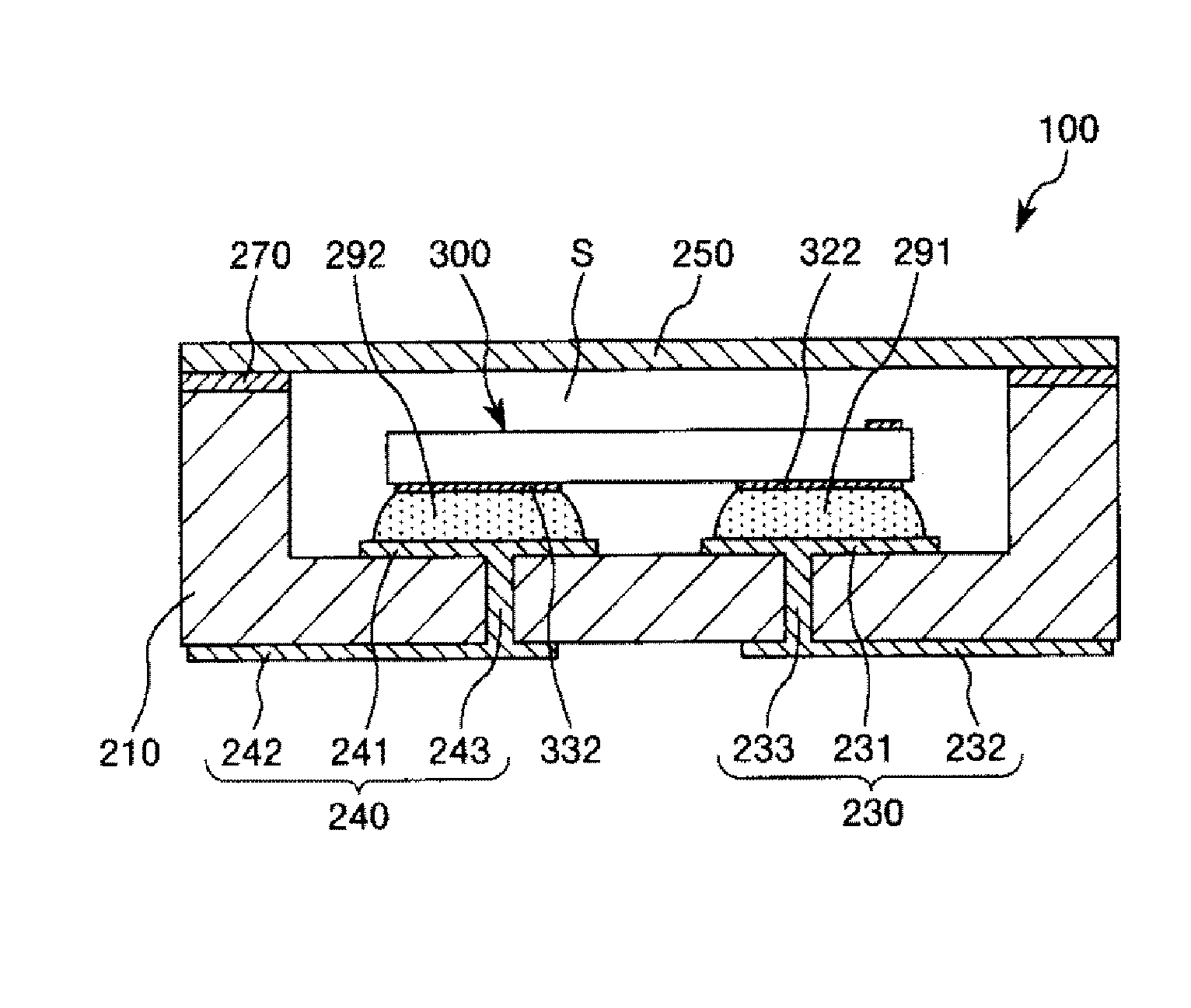

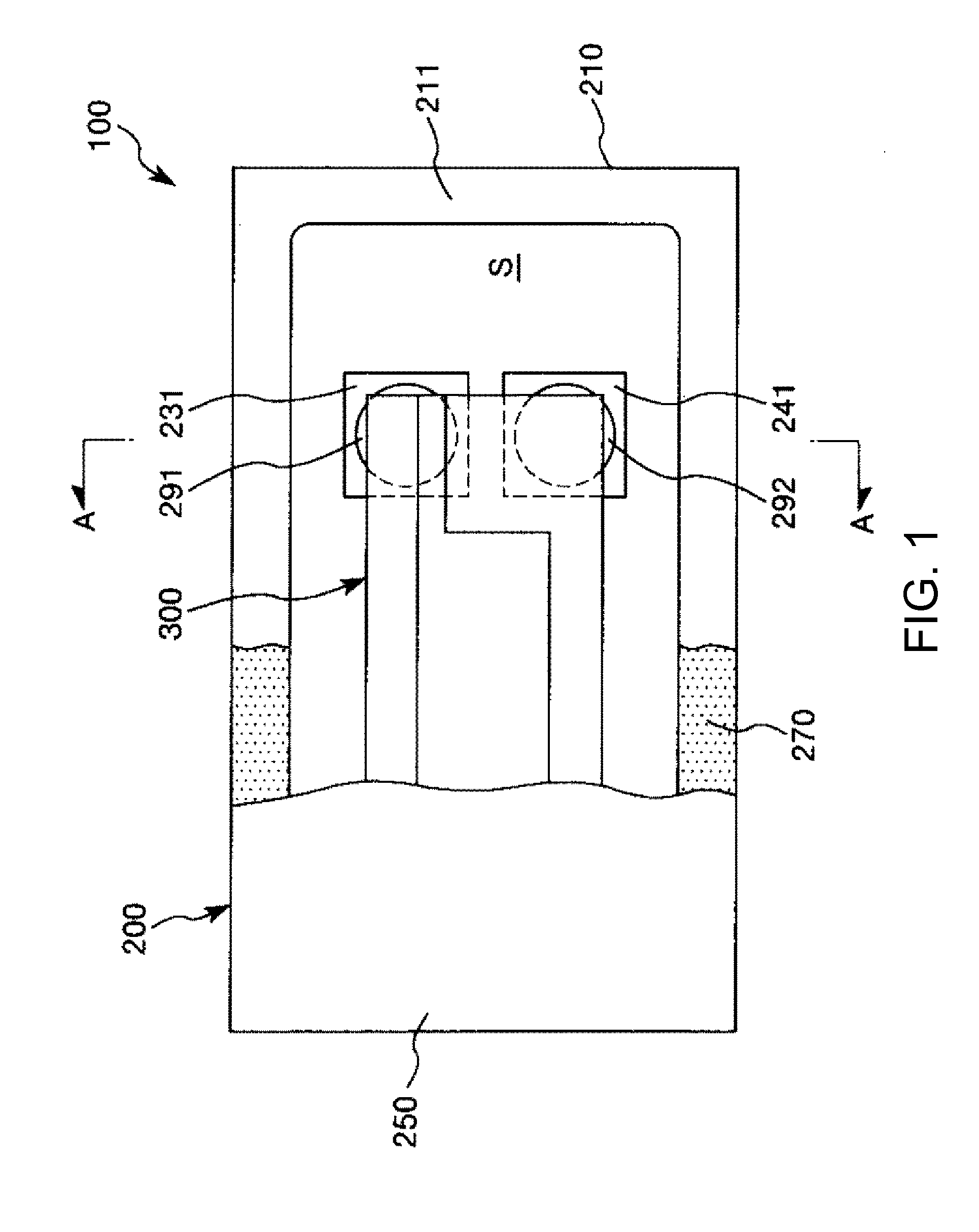

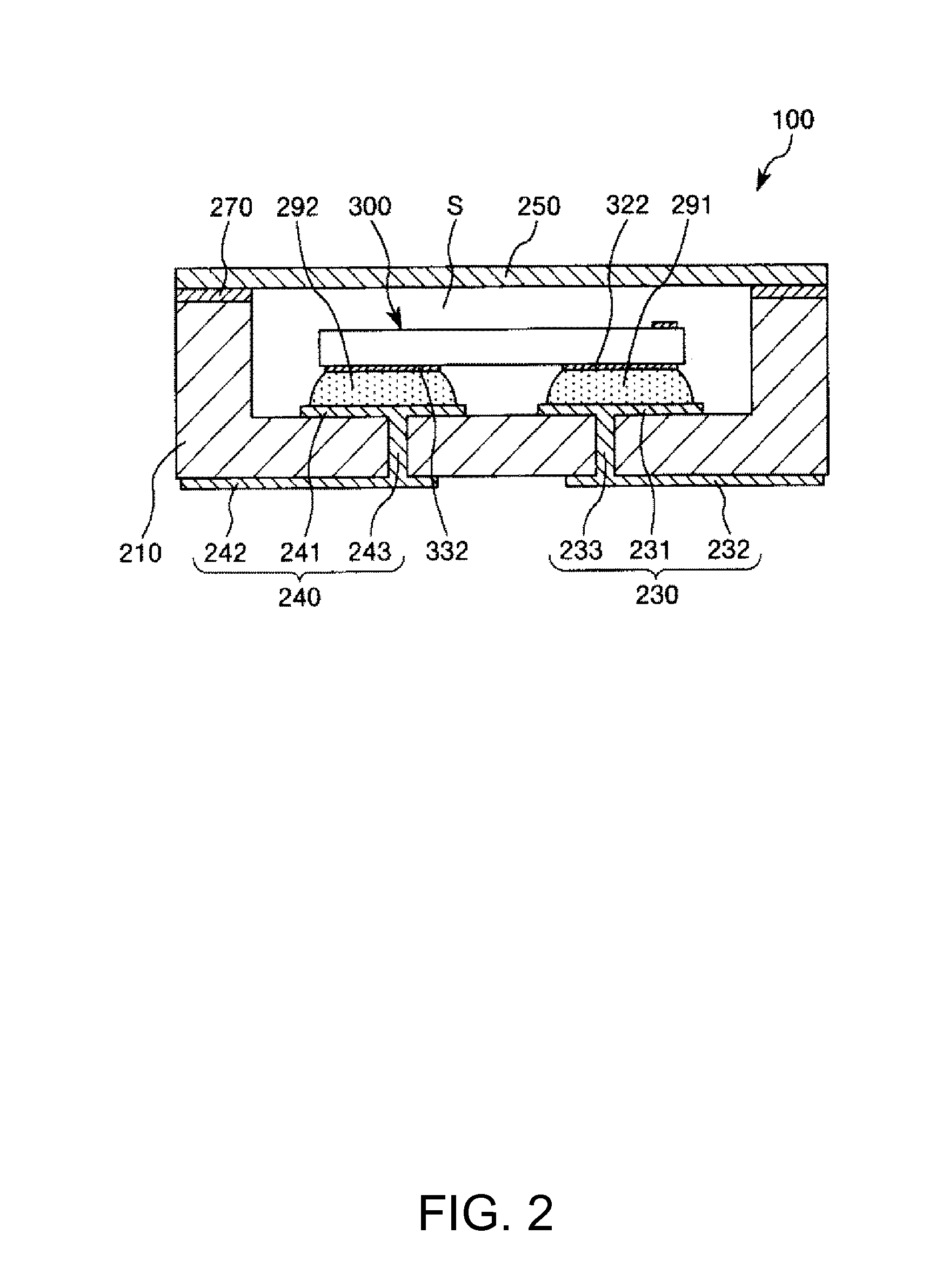

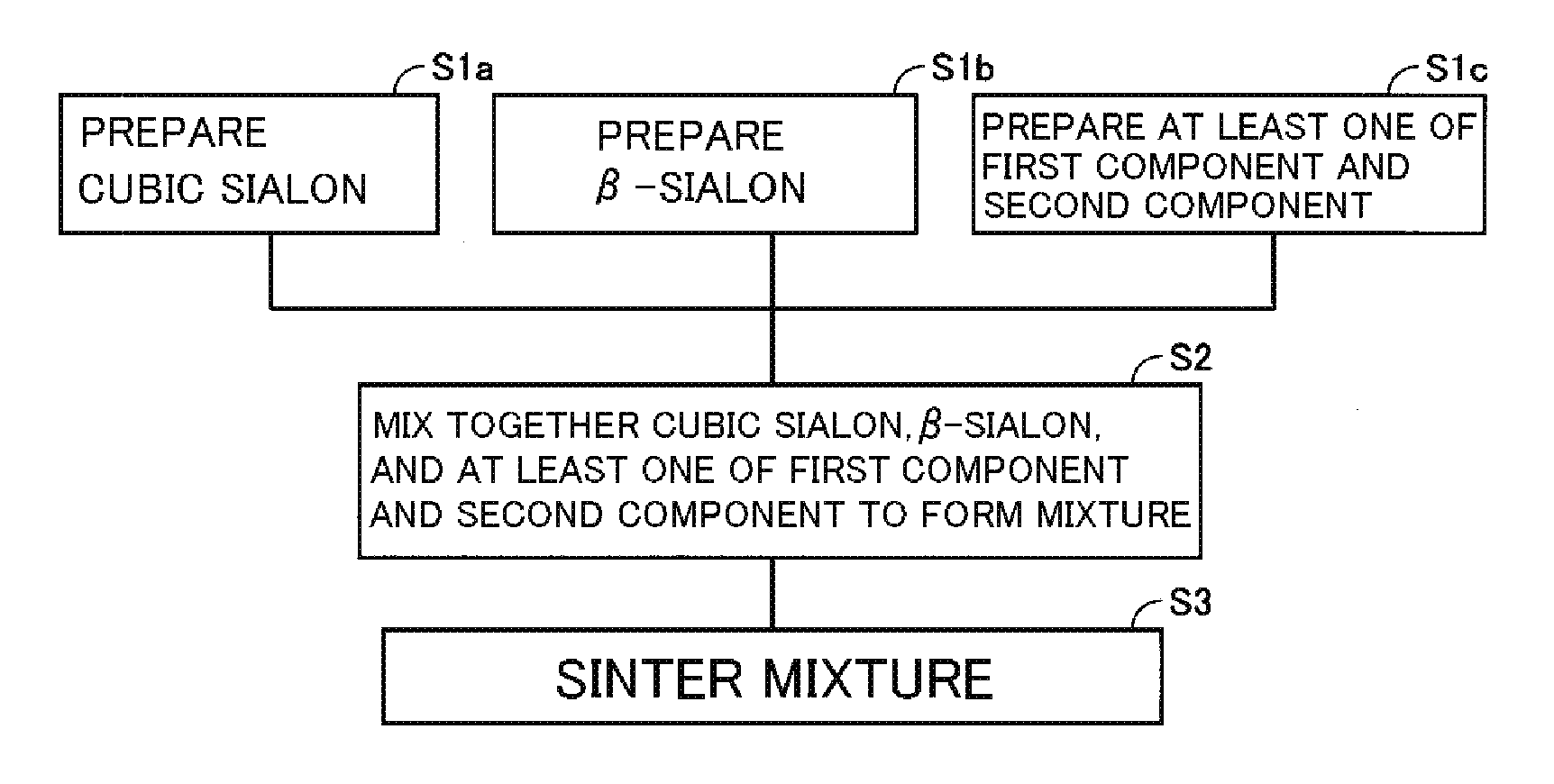

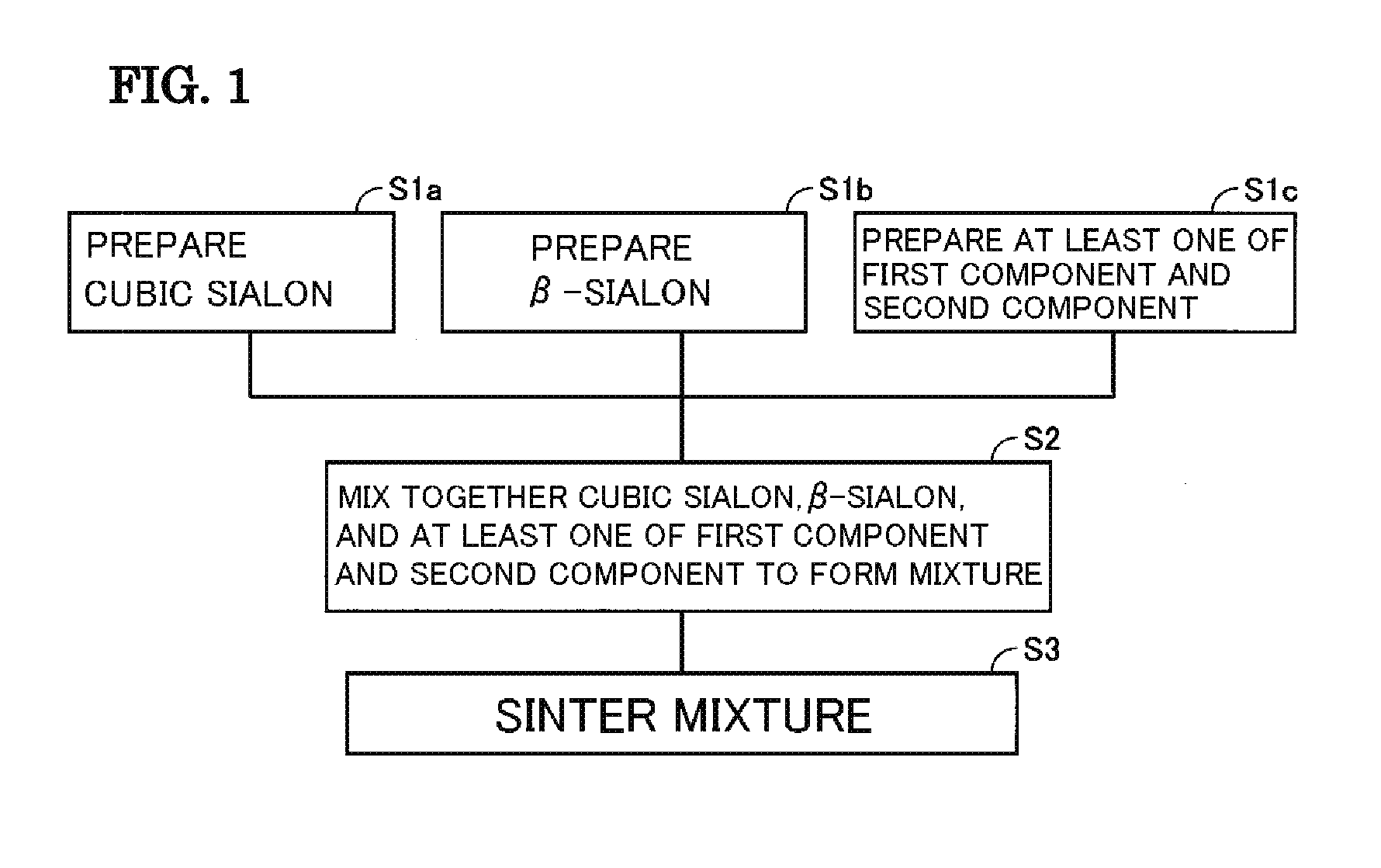

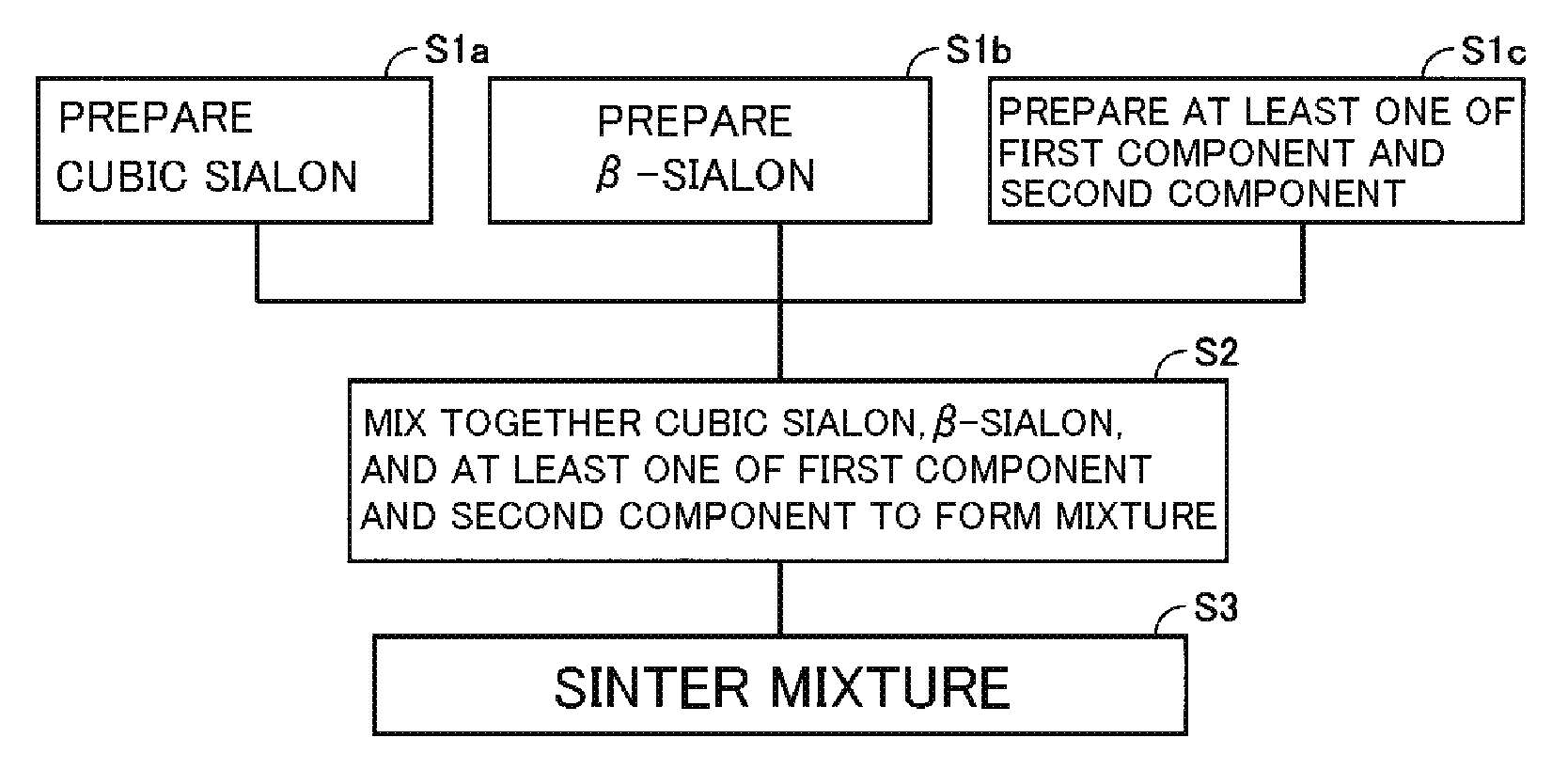

Sintered compact, cutting tool formed using sintered compact, and method for manufacturing sintered compact

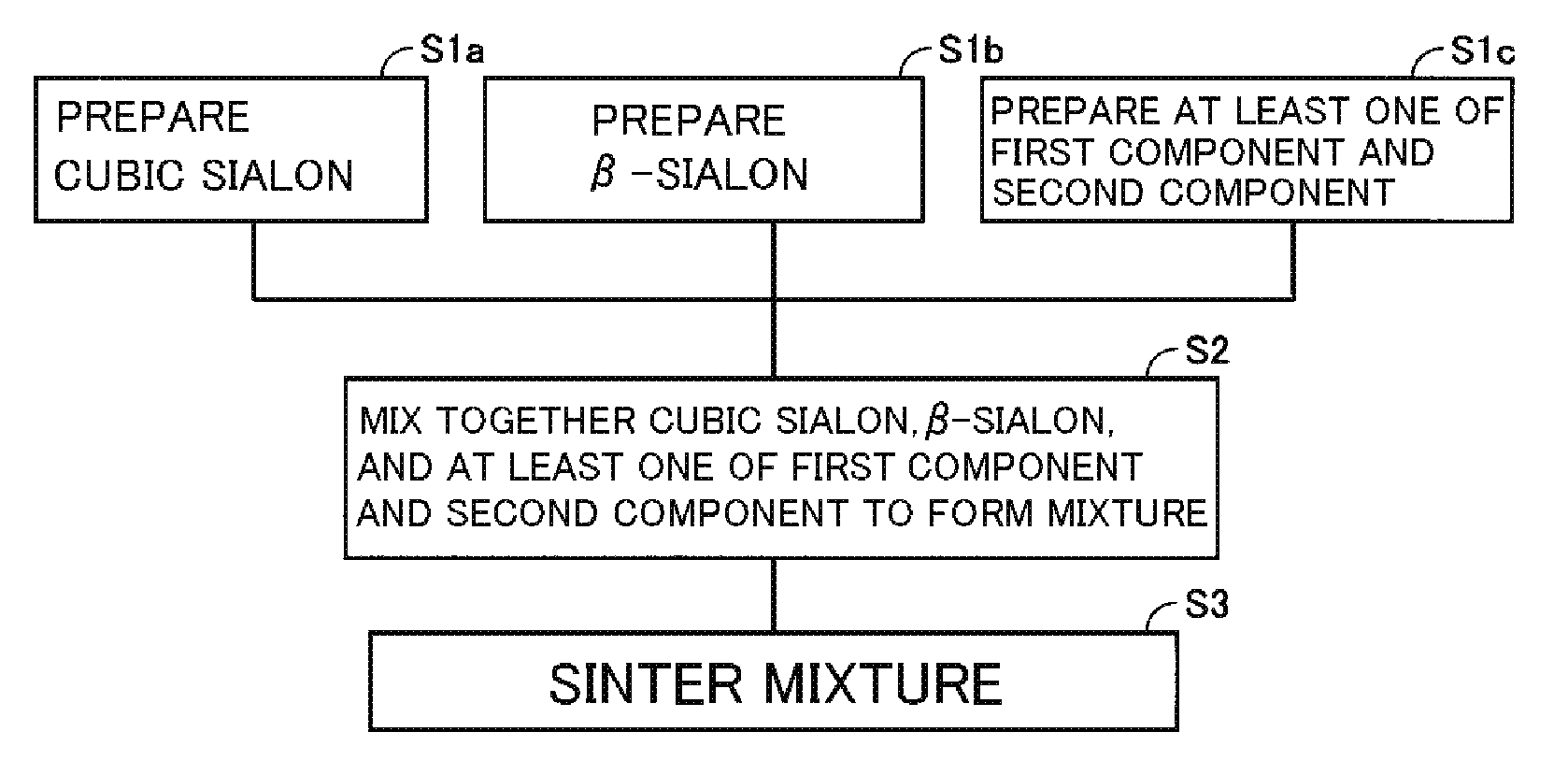

ActiveUS20140178138A1Improve fracture resistanceImprove toughnessCeramic shaping apparatusTurning toolsChemical compoundNitrogen

A sintered compact contains cubic sialon, β-sialon, and at least one of a first component and a second component. The first component is at least one element selected from the group consisting of iron, cobalt, nickel, and group 4 elements, group 5 elements, and group 6 elements of the periodic table. The second component is at least one compound containing at least one element selected from the group consisting of group 4 elements, group 5 elements, and group 6 elements and at least one element selected from the group consisting of carbon, nitrogen, and boron.

Owner:SUMITOMO ELECTRIC IND LTD

Preparation method of 2,5-furandicarboxylic acid

InactiveCN109651311AEasy to prepareThe preparation method is simple and controllableOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsOxygenSolvent

The invention discloses a preparation method of 2,5-furandicarboxylic acid. The method comprises the following steps: uniformly mixing 5-hydroxymethylfurfural, an oxidation catalyst, an alkaline substance and a solvent, and carrying out catalytic conversion in the presence of an oxygen source to obtain the 2,5-furandicarboxylic acid, wherein the oxidation catalyst is an X-Y layered composite oxide, X is one of a group IA element and a group IIA element in the periodic table of elements, and Y is one of a group III element, a group IV element, a group VB element, a group VIB element, a group VIIB element, a group VIII element, a group IB element and a group IIB element in the periodic table of elements. The method has the advantages of high selectivity, few byproducts, mild reaction conditions, low energy consumption, and great reduction of the production cost by using the oxidation catalyst with a low price and avoiding the use of a noble metal catalyst, and the prepared 2,5-furandicarboxylic acid has a high purity and a high yield.

Owner:合肥利夫生物科技有限公司

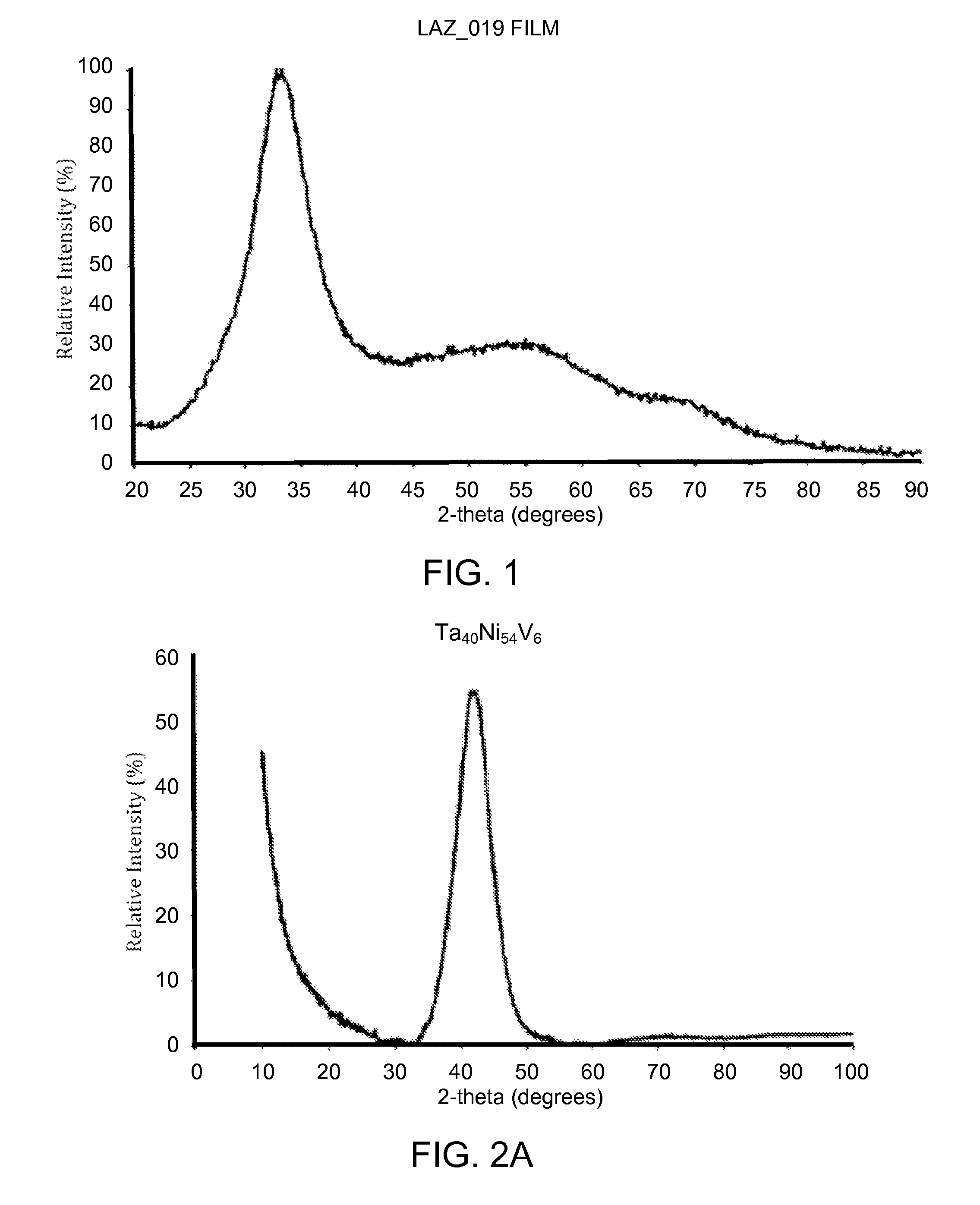

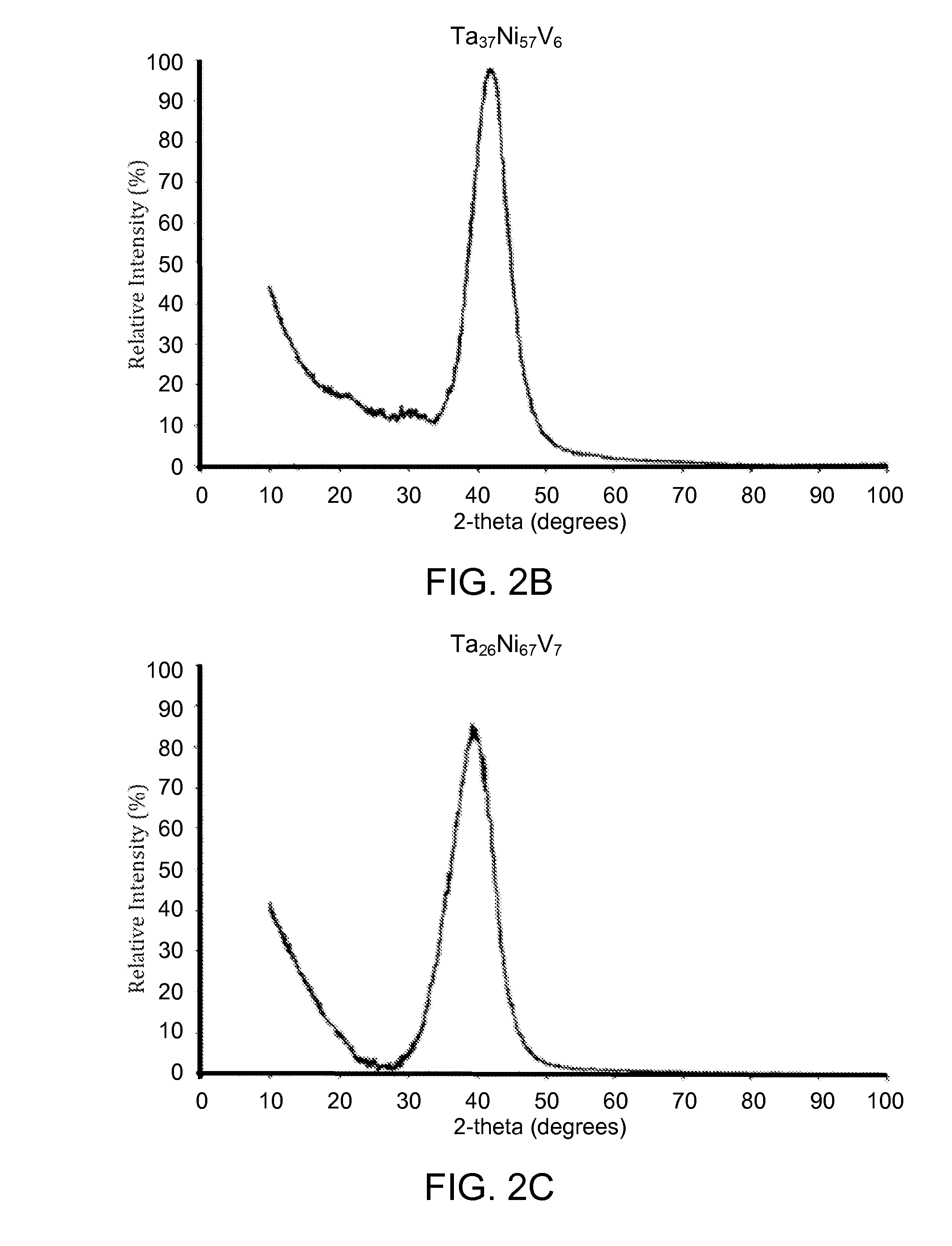

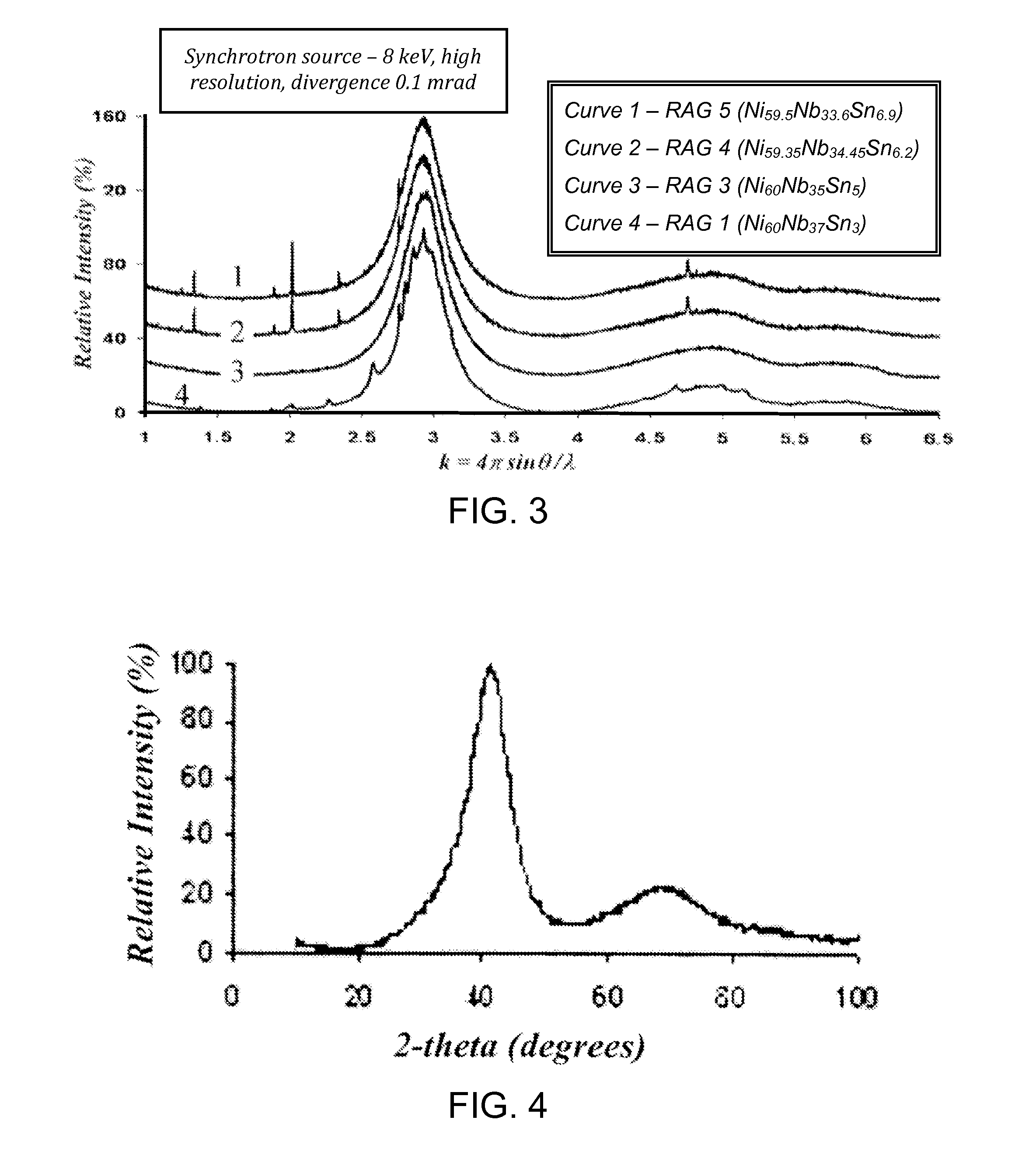

Process for applying amorphous metal

Ni-based refractory metallic glass coatings utilizing periodic table group five element vanadium in combination with other group 5 or 6 elements, particularly tantalum, chromium, or molybdenum, can be formed via co-sputtering with proper control of carrier gas pressure and / or bias voltage. The alloy forms fully amorphous coatings that are not predicted by the usual glass forming ability (GFA) criteria. These alloys exhibit high thermal stability, hardness values greater than TiN, smooth surface finishes, and a wide processing window.

Owner:METAGLASS COATING

Catalyst for production of acetic acid or acetic acid and ethyl acetate, process for its production and process for production of acetic acid or acetic acid and ethyl acetate using it

InactiveUS20030092936A1Improve catalytic performanceLow selectivityOxygen-containing compound preparationOrganic compound preparationAcetic acidGroup 12 element

An acetic acid production catalyst that contains (b) at least one element selected from the group consisting of Group 14 elements, Group 15 elements and Group 16 elements of the Periodic Table and / or (c) at least one element selected from the group consisting of Group 6 elements, Group 7 elements, Group 8 elements, Group 9 elements, Group 10 elements, Group 11 elements and Group 12 elements of the Periodic Table, added to a palladium-loaded catalyst, as well as an acetic acid and ethyl acetate production catalyst that contains (b) at least one compound selected from the group consisting of inorganic acids and salts thereof and / or (c) at least one element selected from the group consisting of Group 14 elements, Group 15 elements and Group 16 elements of the Periodic Table and / or (d) at least one element selected from the group consisting of Group 6 elements, Group 7 elements, Group 8 elements, Group 9 elements, Group 10 elements, Group 11 elements and Group 12 elements of the Periodic Table, added to palladium.

Owner:RESONAC HOLDINGS CORPORATION

Positive electrode active material

ActiveUS20130164623A1Excellent cycle characteristicsLi-accumulatorsNon-aqueous electrolyte accumulator electrodesGroup 6 elementTransition metal

The present invention provides a positive electrode active material. The positive electrode active material is represented by the following formula (I) and has a BET specific surface area of larger than 5 m2 / g and not larger than 15 m2 / g:LixM1yM31-yO2 (I)wherein M1 is at least one transition metal element selected from Group 5 elements and Group 6 elements of the Periodic Table, M3 is at least one transition metal element other than M1 and selected from among transition metal elements excluding Fe, x is not less than 0.9 and not more than 1.3, and y is more than 0 and less than 1.

Owner:SUMITOMO CHEM CO LTD

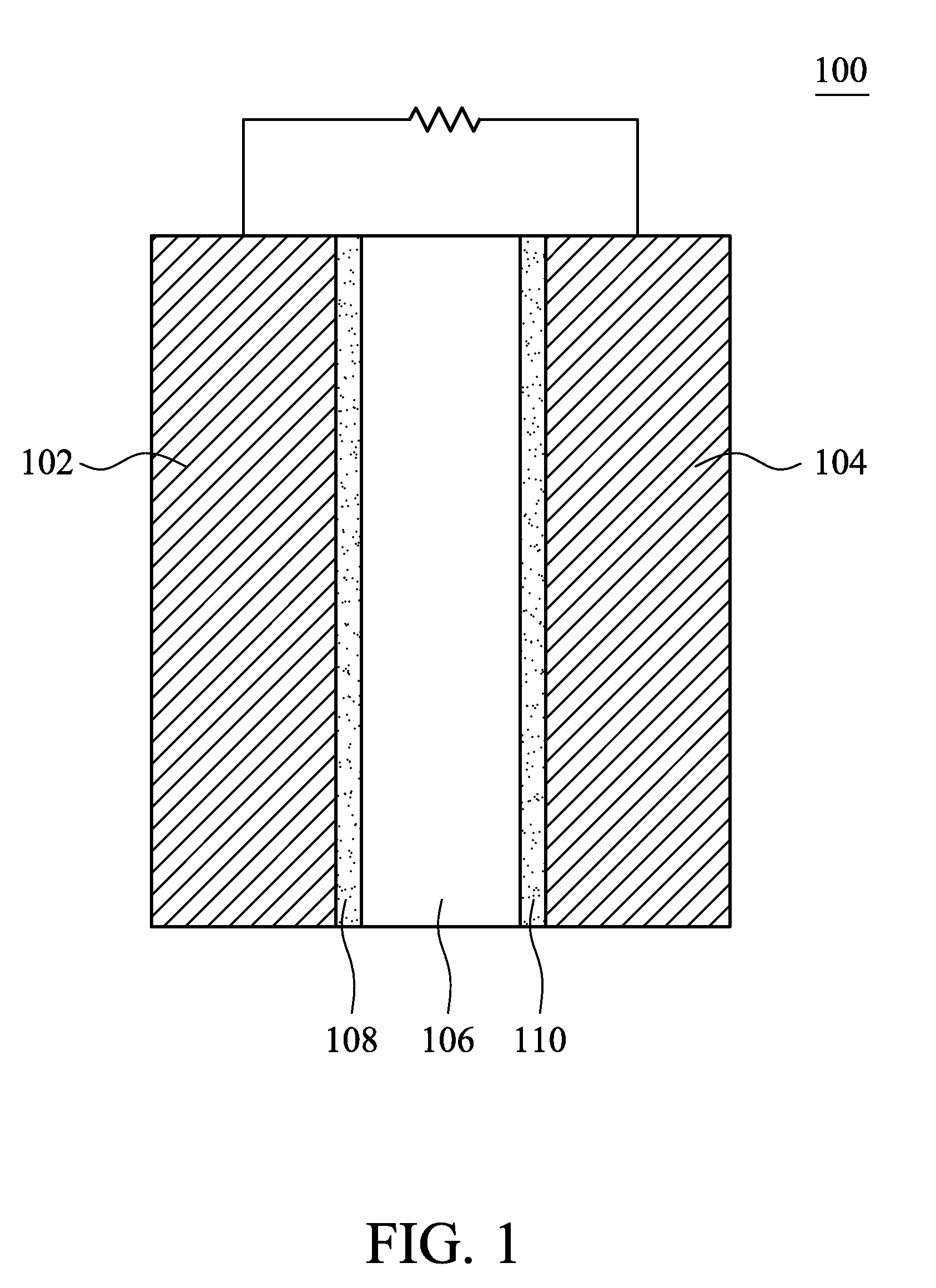

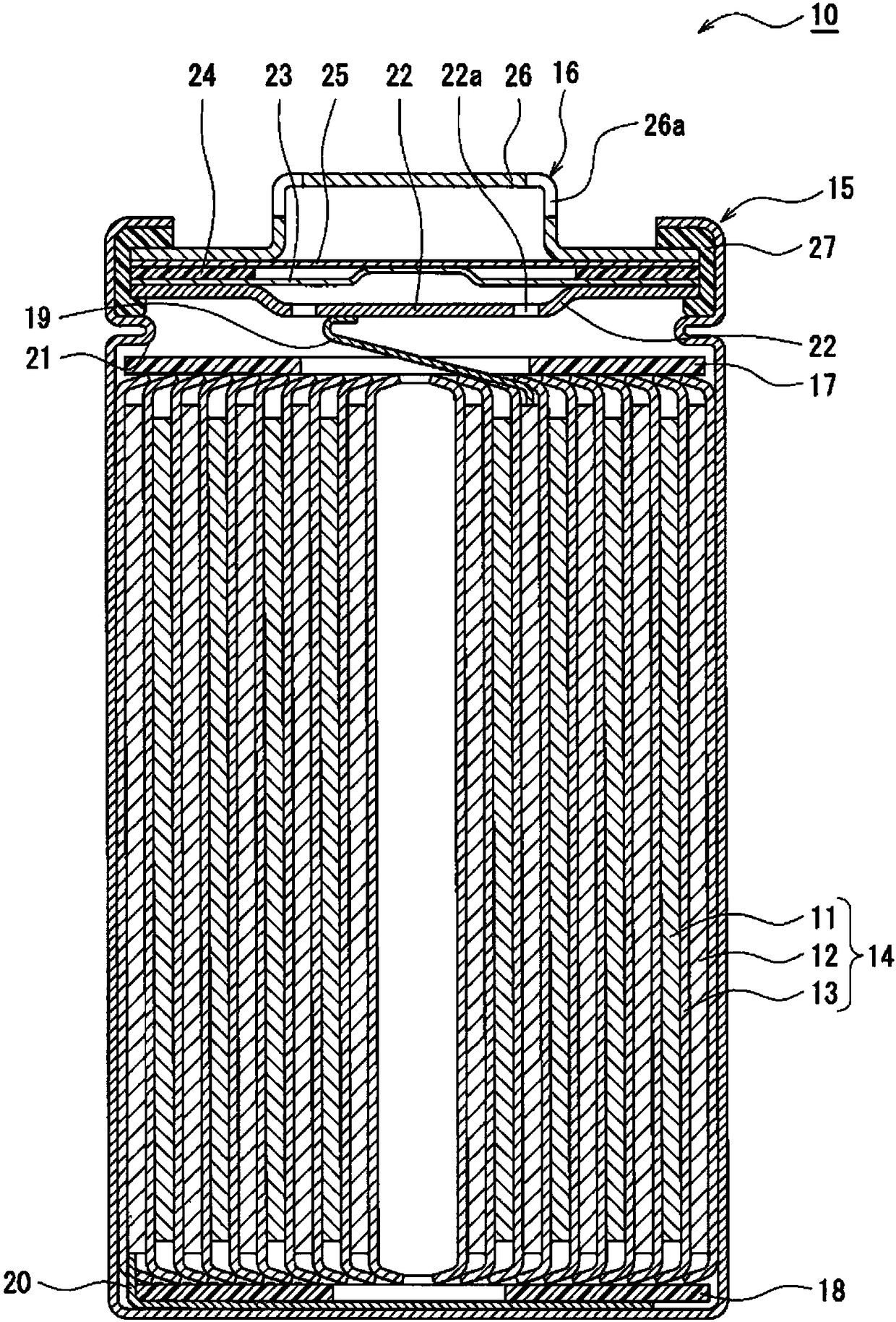

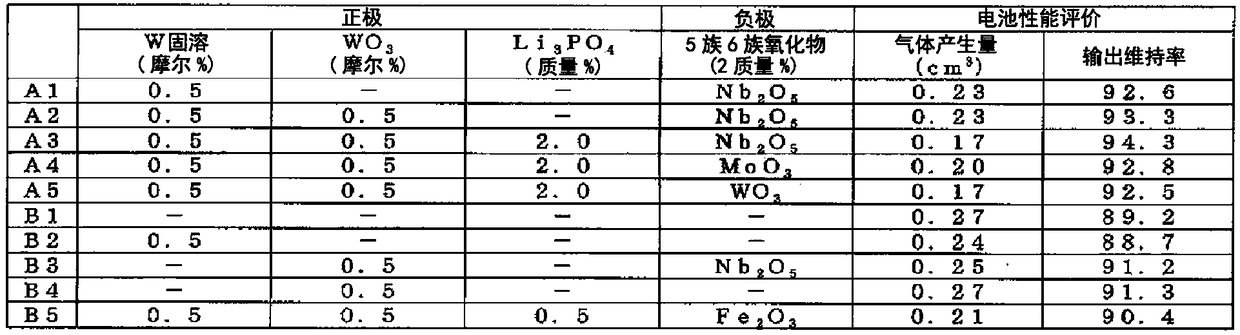

Nonaqueous electrolyte secondary battery

A nonaqueous electrolyte secondary battery wherein a positive electrode mixture layer of a positive electrode contains a lithium transition metal oxide that contains at least nickel (Ni), cobalt (Co),manganese (Mn) and tungsten (W). A negative electrode mixture layer of a negative electrode contains lithium titanate and a group 5 / 6 oxide that is an oxide containing at least one element selected from among group 5 elements and group 6 elements.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Insulating thin film, formation solution for insulating thin film, field-effect transistor, method for manufacturing the same and image display unit

ActiveUS8309954B2Solid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorPeroxide

One embodiment of the present invention is an insulating thin film having a polymer compound, a metallic atom bonded to the polymer compound through an oxide atom and selected from a group 4 element, a group 5 element, a group 6 element, a group 13 element, zinc or tin, and an organic molecule bonded to the metallic atom through the oxide atom or a nitrogen atom.

Owner:TOPPAN PRINTING CO LTD

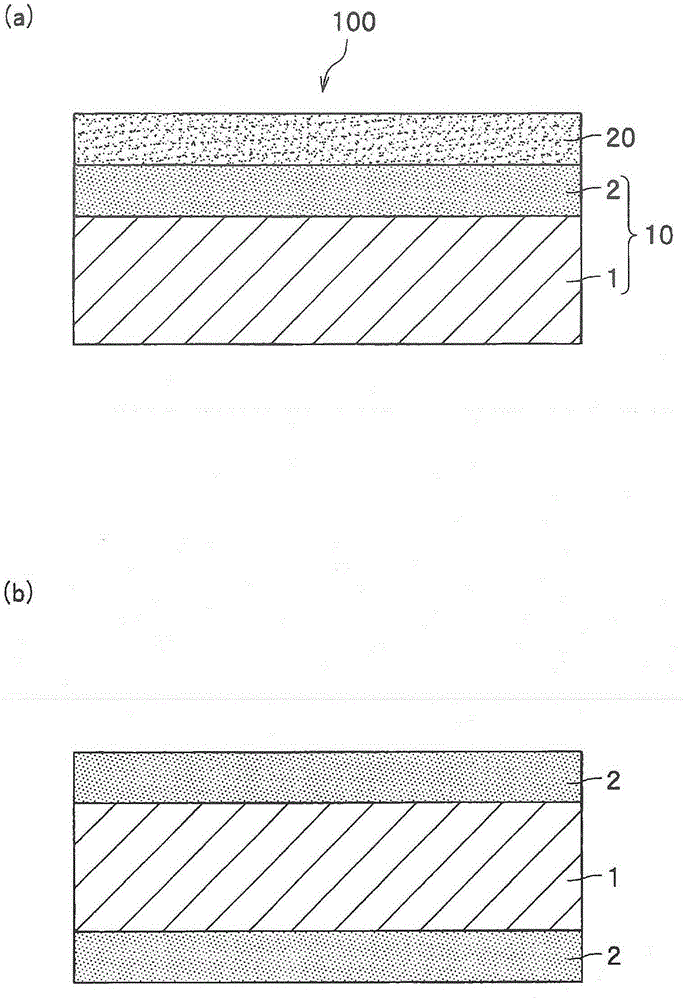

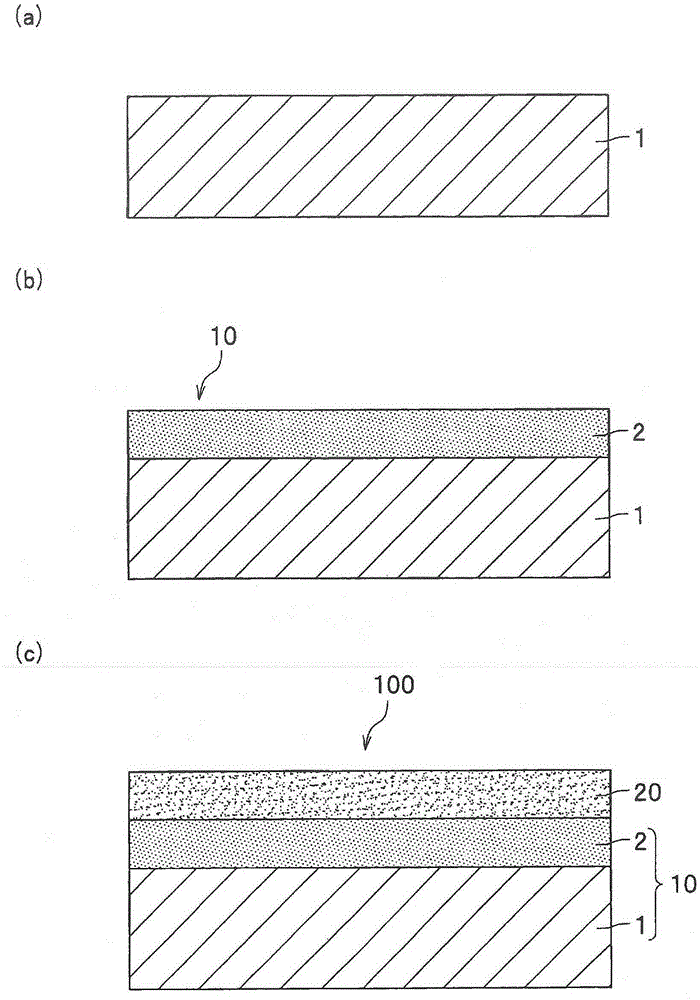

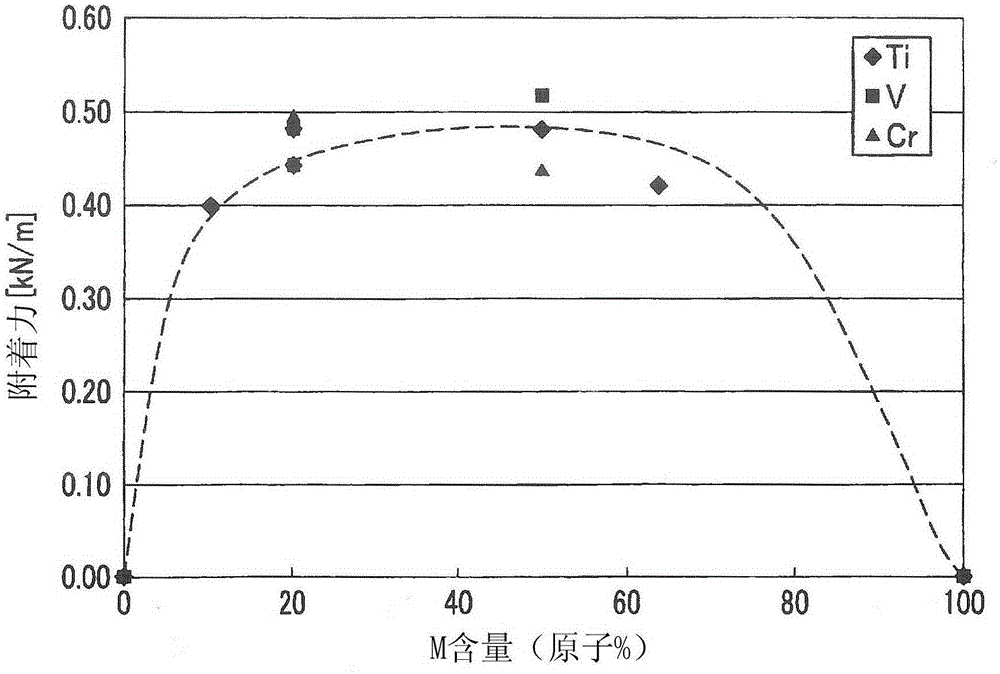

Positive electrode current collector for lithium ion secondary battery, positive electrode for lithium ion secondary battery, and process for production of positive electrode current collector for lithium ion secondary battery

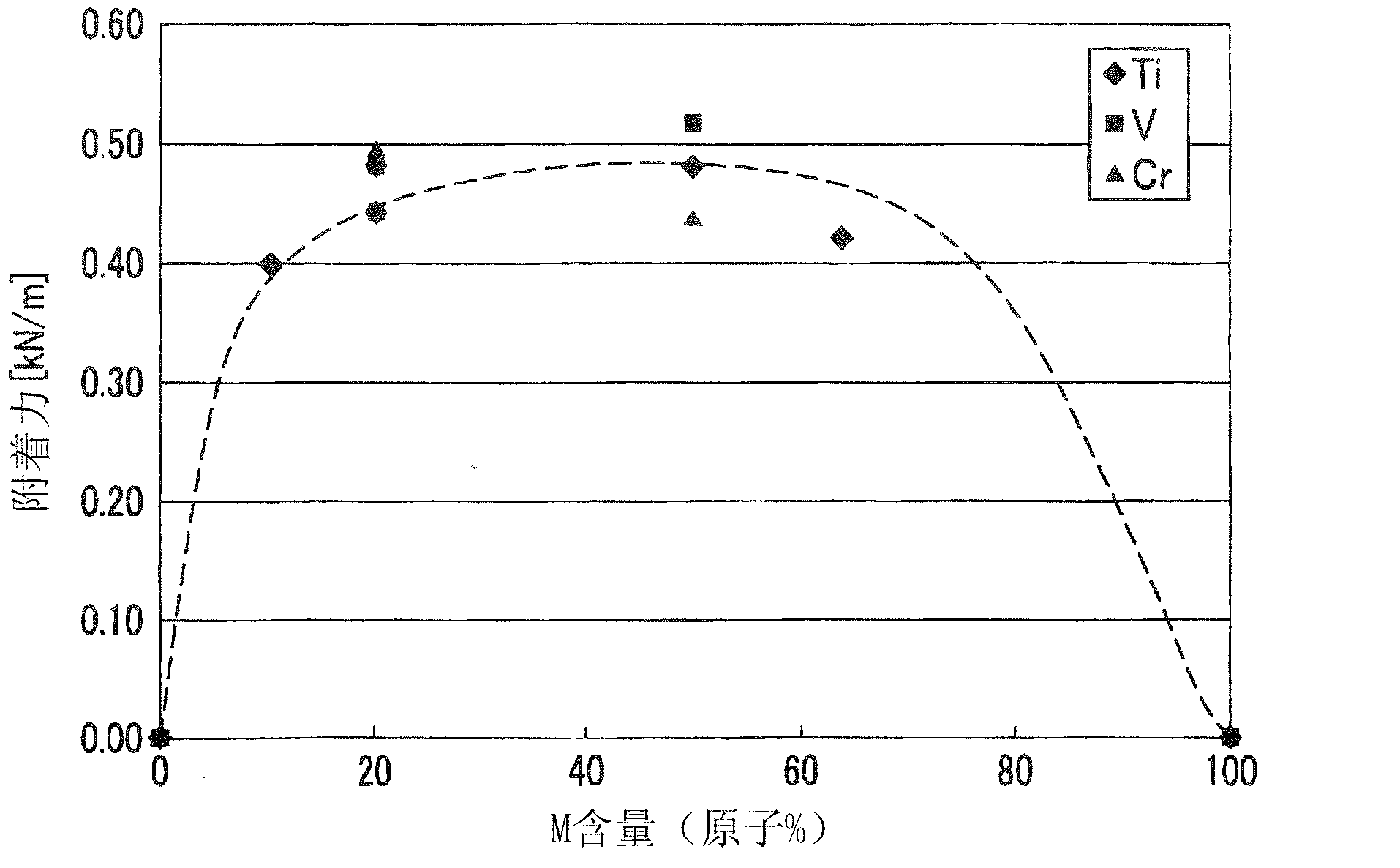

InactiveCN102763253AEasy and reliableDissolution inhibitionElectrode carriers/collectorsSecondary cellsLithiumSurface layer

Disclosed is a positive electrode current collector for a lithium ion secondary battery, which is characterized by comprising an aluminum foil comprising pure aluminum or an aluminum alloy and a surface layer formed on one surface or both surfaces of the aluminum foil, wherein the surface layer contains C in an amount of 10 to 95 at.% and additionally contains at least one element selected from Group 4 to Group 6 elements in an amount of 5 to 90 at.%. Also disclosed is a positive electrode for a lithium ion secondary battery, which is characterized by having a positive electrode active material layer that covers the surface layer of the positive electrode current collector for a lithium ion secondary battery. It becomes possible to prevent the elution of the current collector into an electrolytic solution to improve the adhesion between the current collector and the active material in the interface therebetween and increase the service life of a battery.

Owner:KOBE STEEL LTD

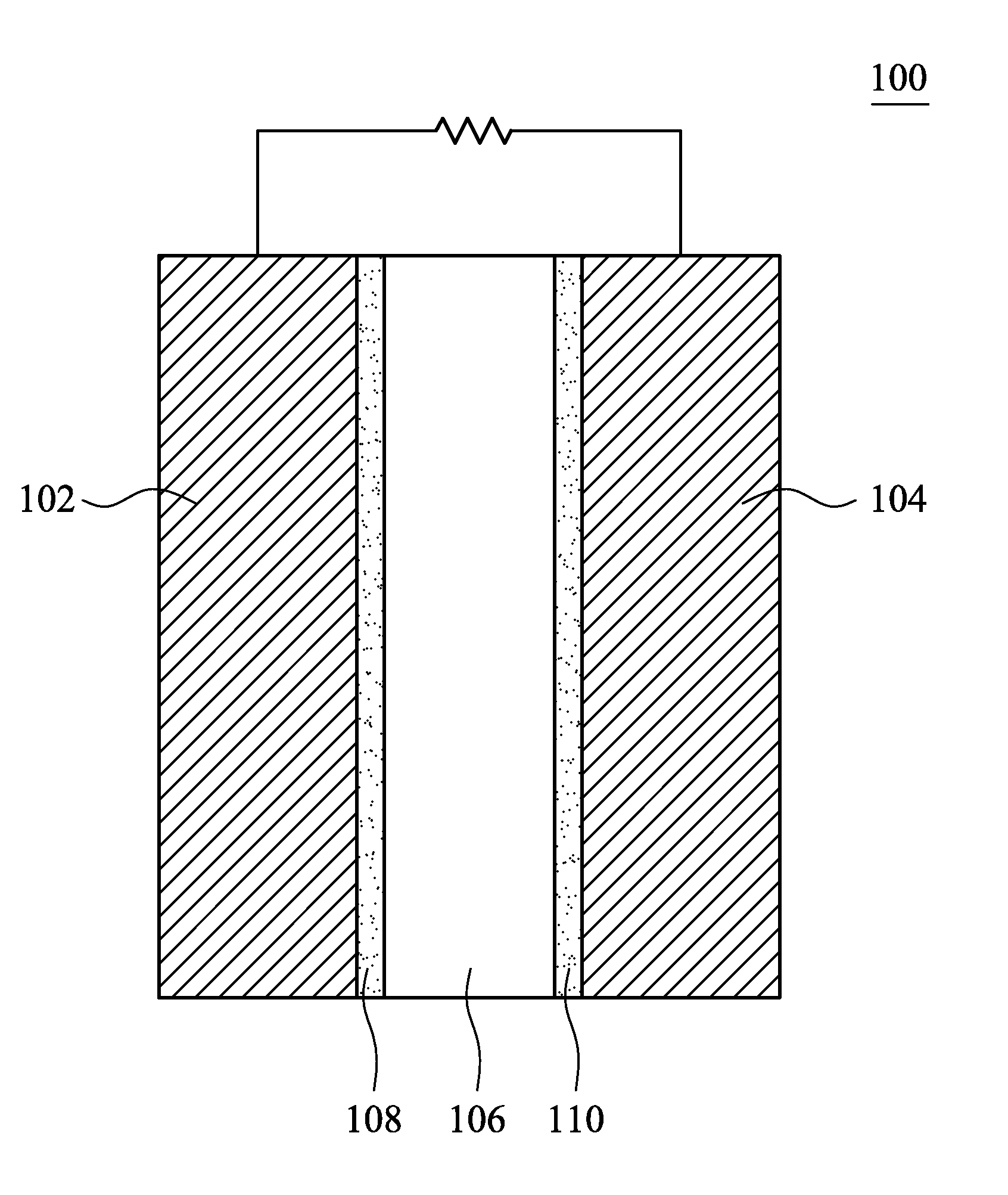

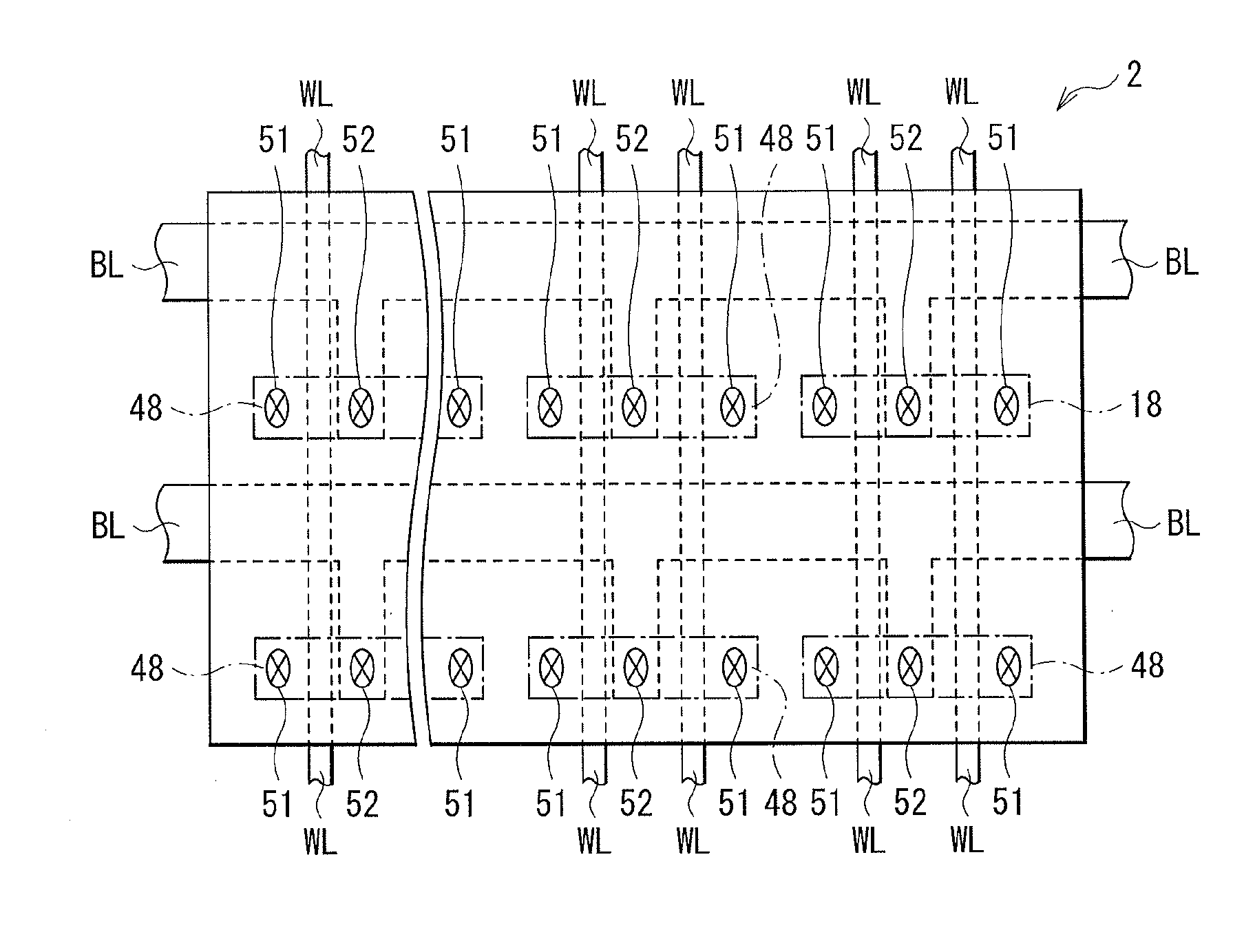

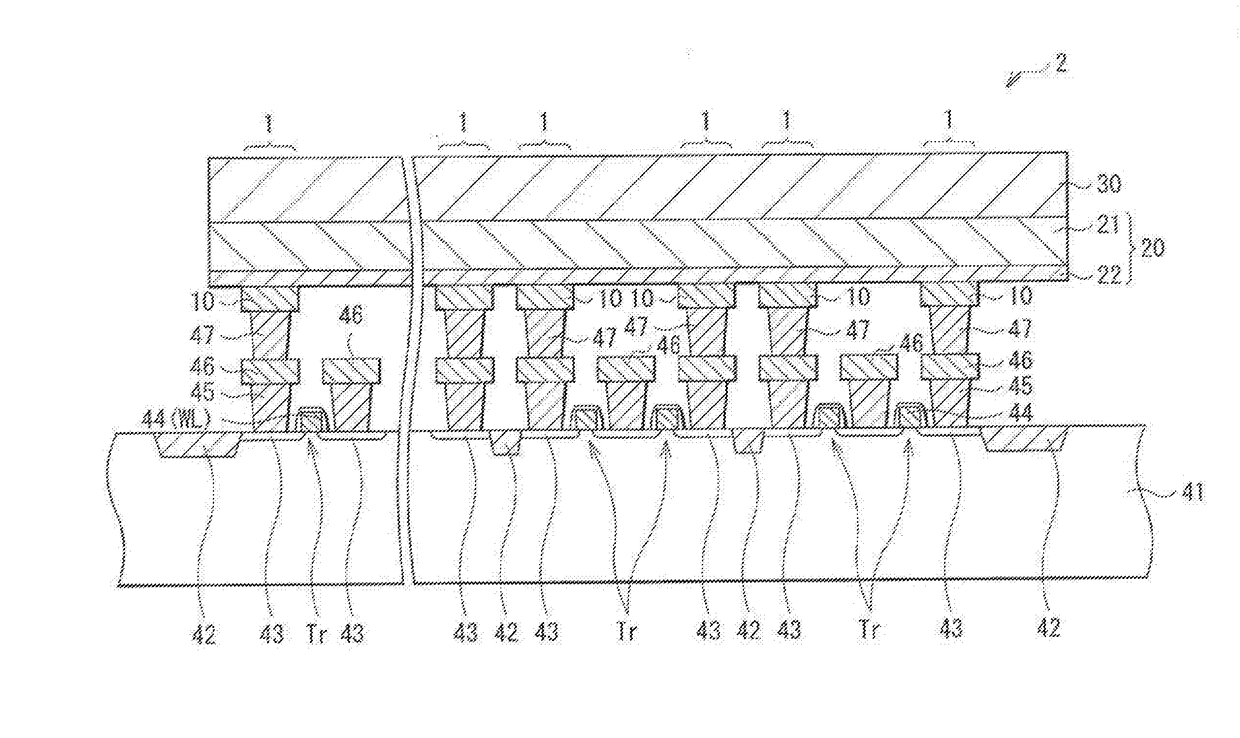

Storage device and storage unit

ActiveUS20150318471A1Good chemical stabilityImprove thermal stabilityDigital storageBulk negative resistance effect devicesElectrical resistance and conductanceSulfur

There are provided a storage device and a storage unit capable of improving retention performance of an intermediate resistance value in writing at a low current, and a storage device and a storage unit capable of reducing random telegraph noise. A storage device of one embodiment of the present technology includes a first electrode, a storage layer, and a second electrode in this order, and the storage layer includes: an ion source layer including one or more kinds of chalcogen elements selected from tellurium (Te), sulfur (S), and selenium (Se), and one or more kinds of transition metal elements selected from Group 4 elements, Group 5 elements, and Group 6 elements of the periodic table; and a resistance change layer including boron (B) and oxygen (O). A storage device of another embodiment of the present technology includes the above-described ion source layer and a resistance change layer including one or more kinds of transaction metal elements selected from Group 4 elements, Group 5 elements, and Group 6 elements of the periodic table, and oxygen (O).

Owner:SONY SEMICON SOLUTIONS CORP

Olefin production process

ActiveUS8552239B2High selectivityMolecular sieve catalystsHeterogenous catalyst chemical elementsHeteropoly acidIon exchange

A novel olefin production process is provided which can be established as an industrial and practical process capable of producing olefins by directly reacting a ketone and hydrogen in a single reaction step. In particular, a novel olefin production process is provided in which propylene is obtained with high selectivity by directly reacting acetone and hydrogen.The olefin production process according to the present invention includes reacting a ketone and hydrogen in the presence of at least one dehydration catalyst and a silver-containing catalyst, and the at least one dehydration catalyst is selected from metal oxide catalysts containing a Group 6 element, zeolites, aluminas and heteropoly acid salts in which part or all the protons in heteropoly acids are exchanged with metal cations.

Owner:MITSUI CHEM INC

Coated member

ActiveUS8557405B2Improve adhesionExcellent in wear resistance and fracture resistance and oxidation resistancePigmenting treatmentOther chemical processesX-rayGroup 6 element

A coated member includes a base material and a coating film formed on the surface thereof. At least one layer in the coating film is a hard film of a cubic metal compound including at least one element selected from the group consisting of the group 4 elements (Ti, Zr, Hf, etc.), group 5 elements (V, Nb, Ta, etc.) and group 6 elements (Cr, Mo, W, etc.) of the periodic table, Al, Si, B, Y and Mn together with at least one element selected from the group consisting of C, N and O. In the pole figure for the face (111) of the hard film, the X-ray intensity distribution in the α-axis shows the maximum intensity in the α-angle range of 50-65°. In the pole figure for the face (200), the X-ray intensity distribution in the α-axis shows the maximum intensity in the α-angle range of 60-80°.

Owner:TUNGALOY CORP

Circuit board, method for manufacturing circuit board, electronic device, electronic apparatus, and moving object

InactiveCN104425390ASemiconductor/solid-state device detailsSolid-state devicesElectrical conductorGroup 6 element

A circuit board includes a ceramics substrate composed of ceramics and a conductor portion provided on the ceramics substrate. The conductor portion is composed of a stacked body including, in order from the ceramics substrate side, an under layer that contains a Group 6 element and a glass material, and a metal layer that contains a low-melting-point metal. A portion of the low-melting-point metal constituting the metal layer migrates to the under layer.

Owner:SEIKO EPSON CORP

Catalyst for hydrogen peroxide decomposition, process for producing the same, and method for decomposing hydrogen peroxide using the catalyst

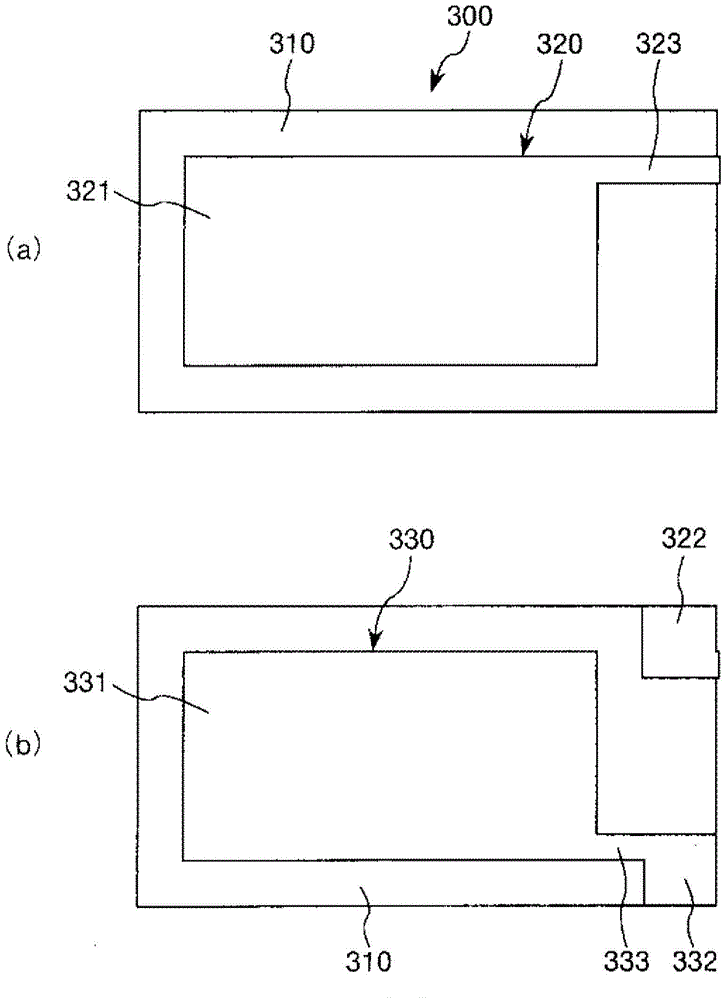

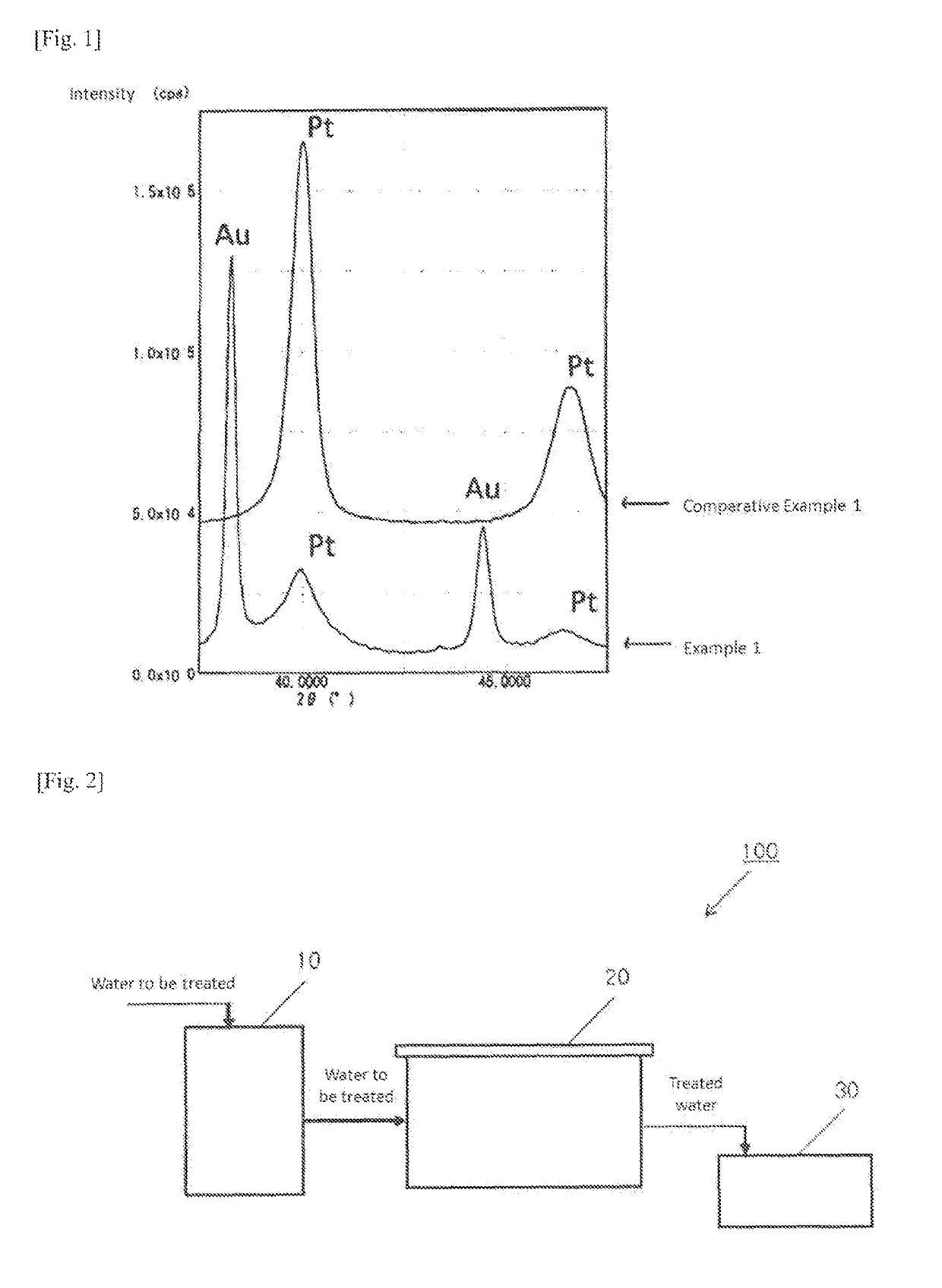

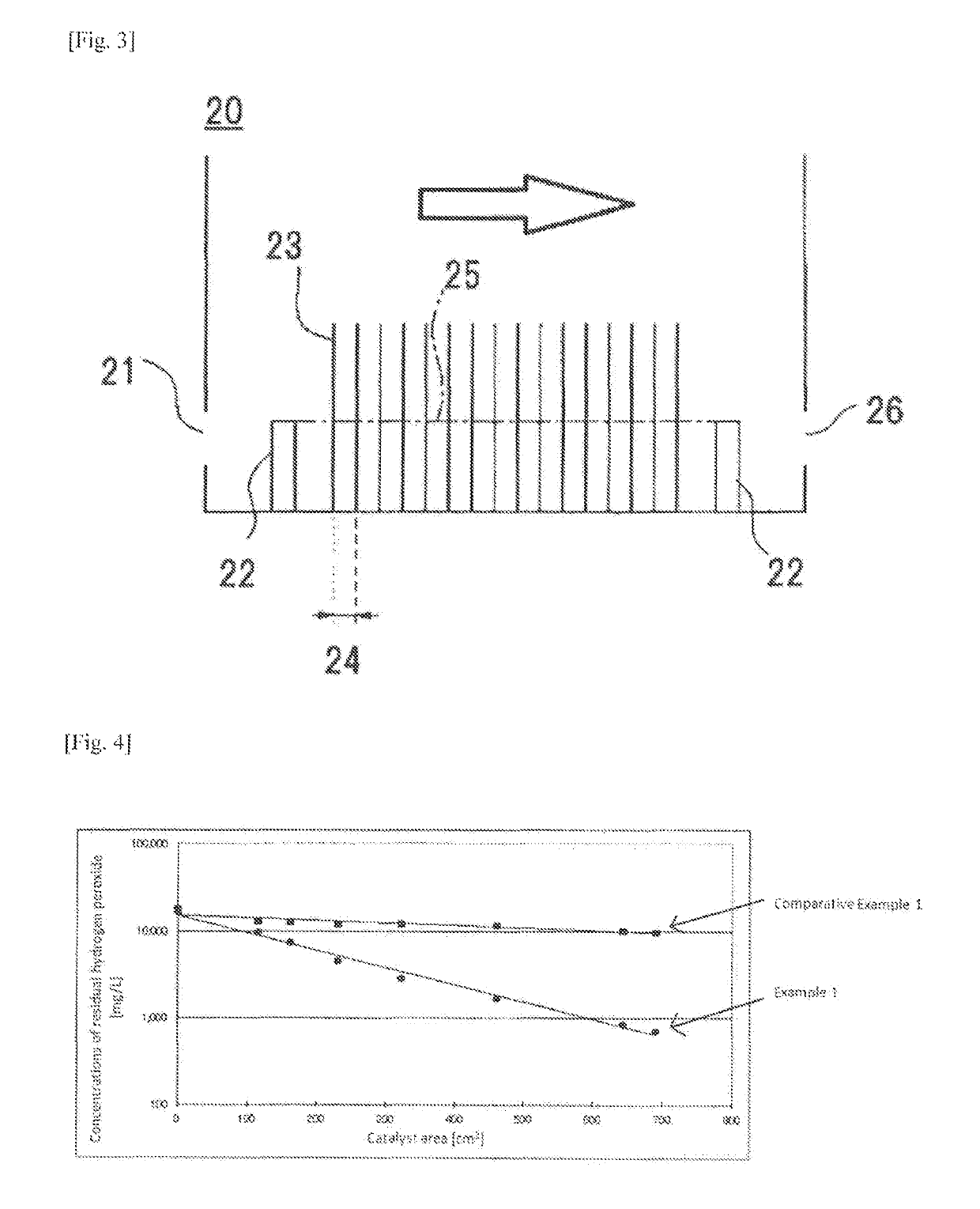

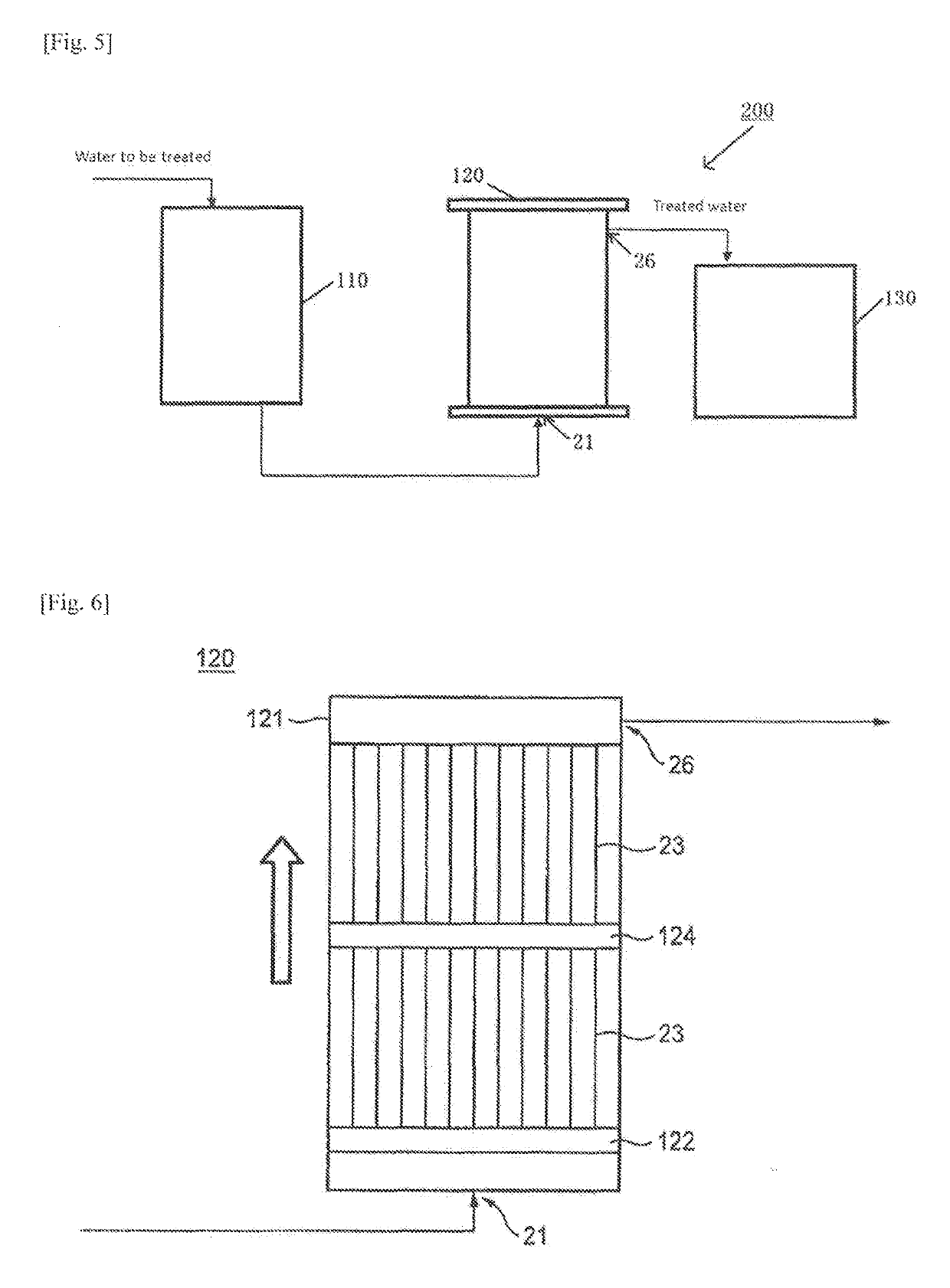

ActiveUS10441943B2Efficient decompositionLess apt to dissolve awayWater contaminantsCatalyst activation/preparationHydrogen peroxide breakdownDecomposition

The present invention provides a catalyst for hydrogen peroxide decomposition with which hydrogen peroxide present in acid-containing water to be treated can be efficiently decomposed at low cost and which is less apt to dissolve away in the water being treated, can be stably used over a long period, and renders acid recovery and recycling possible. The present invention has solved the problems with a catalyst for hydrogen peroxide decomposition which is for use in decomposing hydrogen peroxide present in acid-containing water to be treated, the catalyst including a base and, a catalyst layer that is amorphous, includes a platinum-group metal having catalytic function and a Group-6 element metal having catalytic function and is formed over the base.

Owner:TANAKA PRECIOUS METAL IND

Nonaqueous electrolyte secondary battery

ActiveUS20180366724A1Reduce temperature riseSecondary cellsPositive electrodesLithiumPhysical chemistry

A nonaqueous electrolyte secondary battery includes a positive electrode, a negative electrode, and a nonaqueous electrolyte. The positive electrode contains a lithium transition metal oxide, at least one element of a group 5 element and group 6 element in the periodic table, and a phosphoric acid compound. The nonaqueous electrolyte contains a lithium salt containing a P—O bond and a P—F bond.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

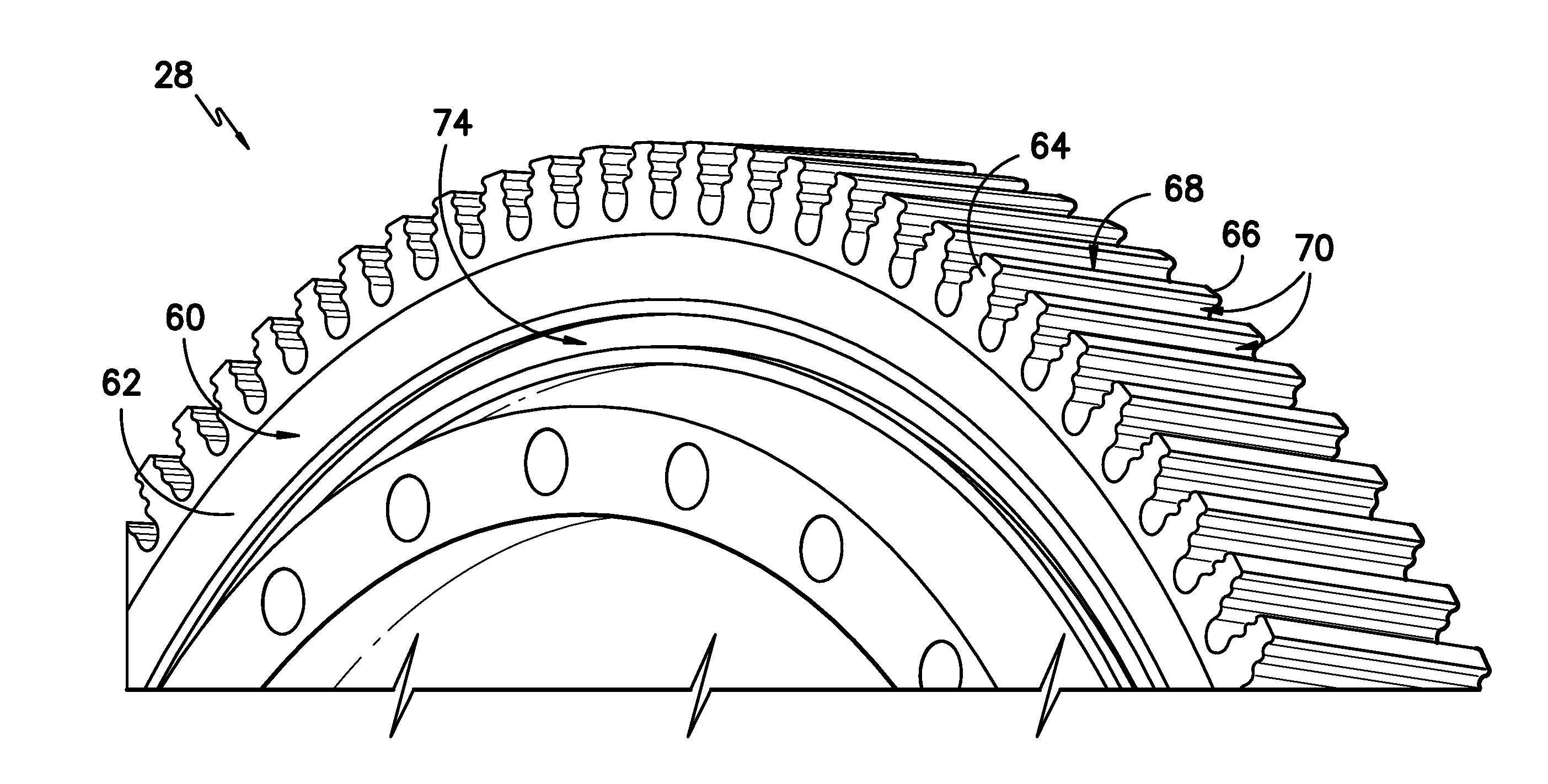

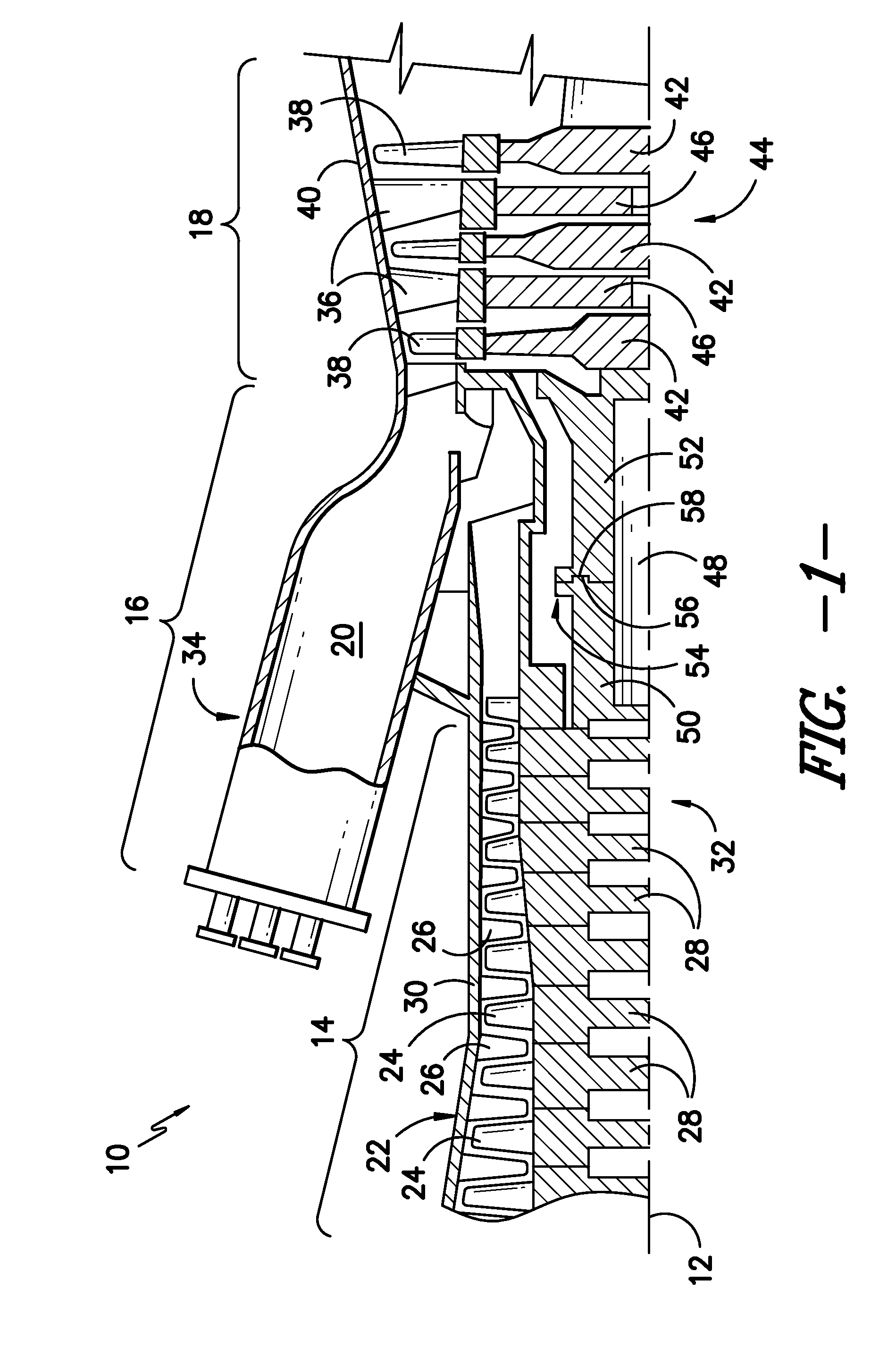

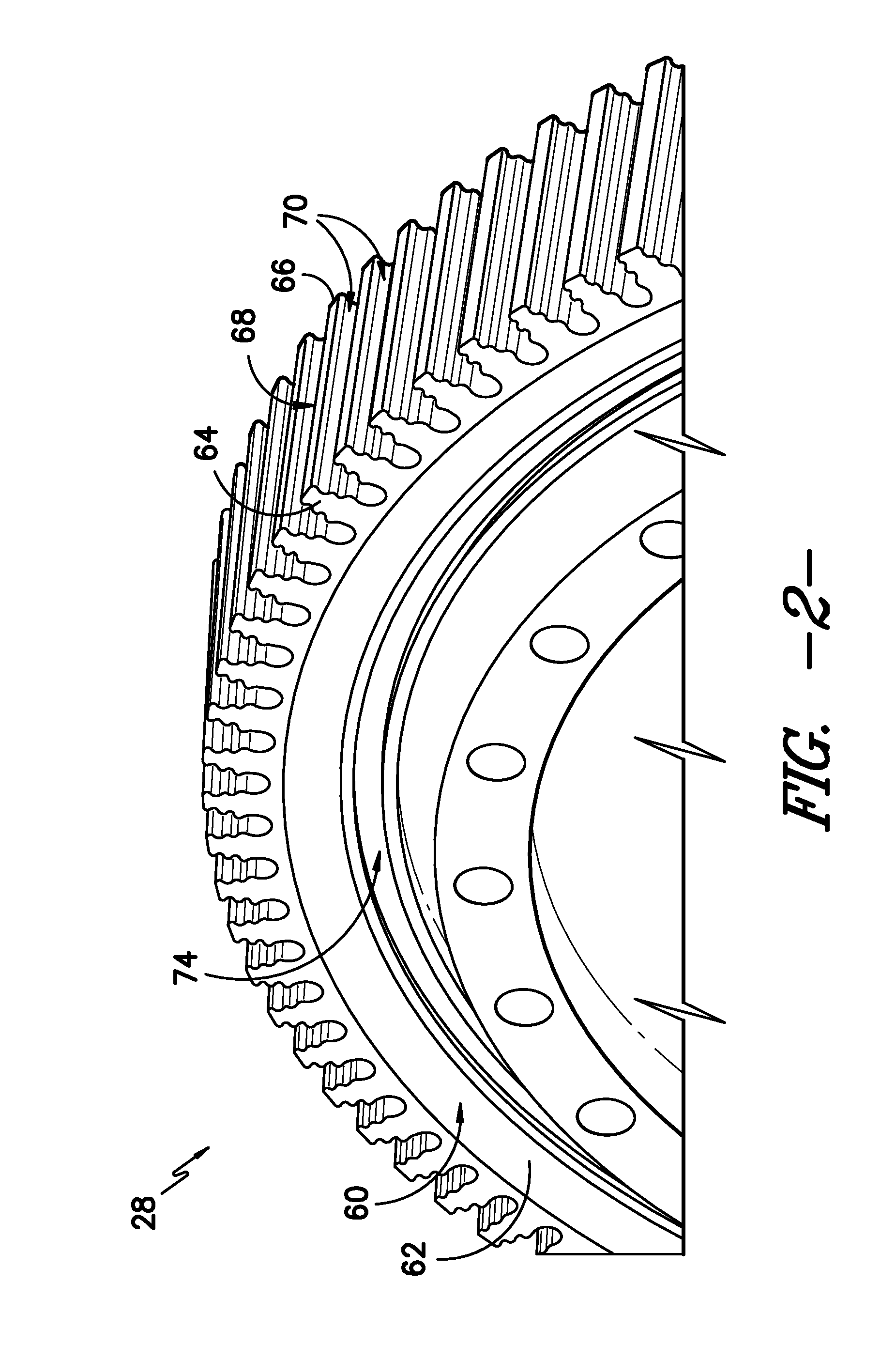

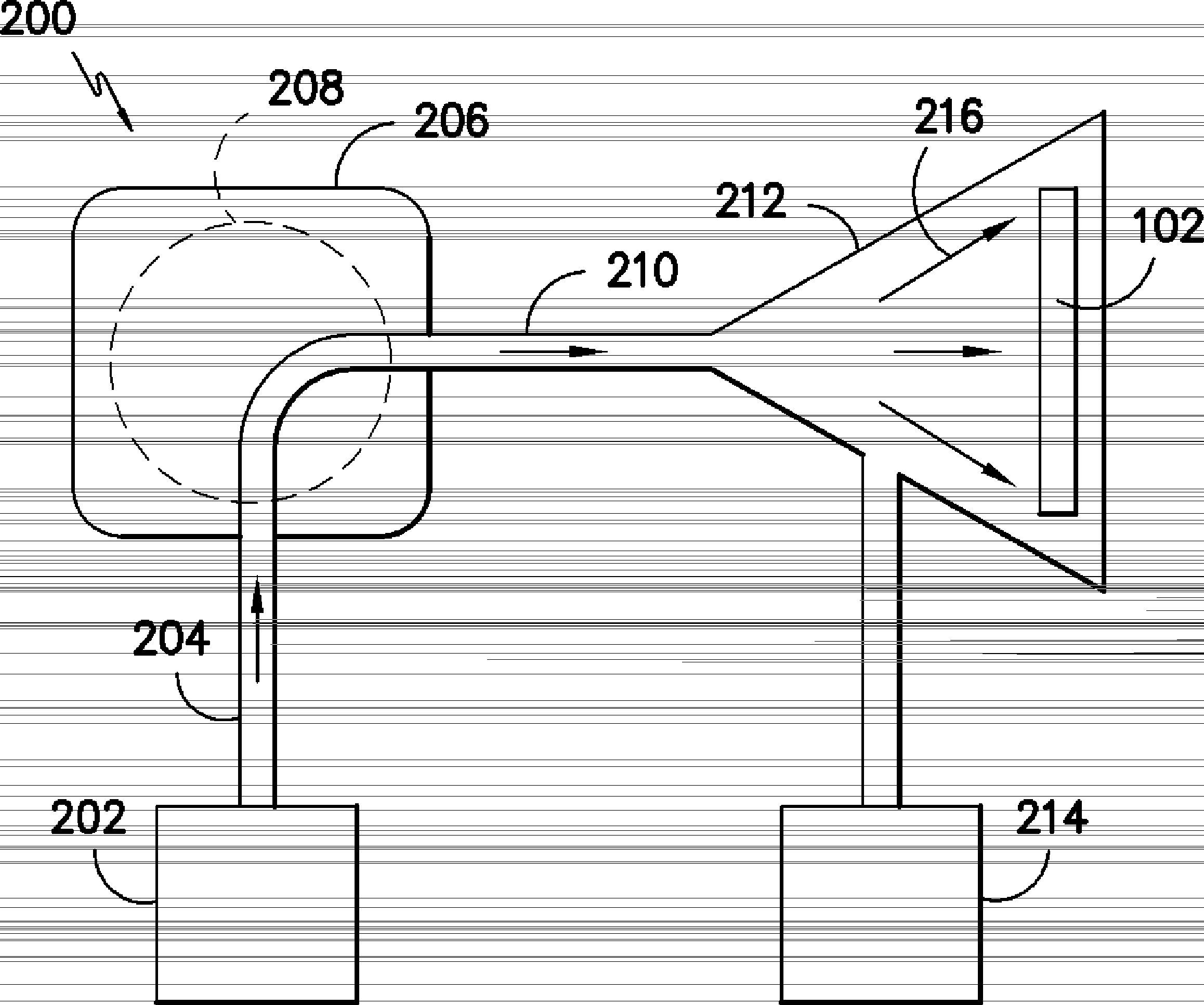

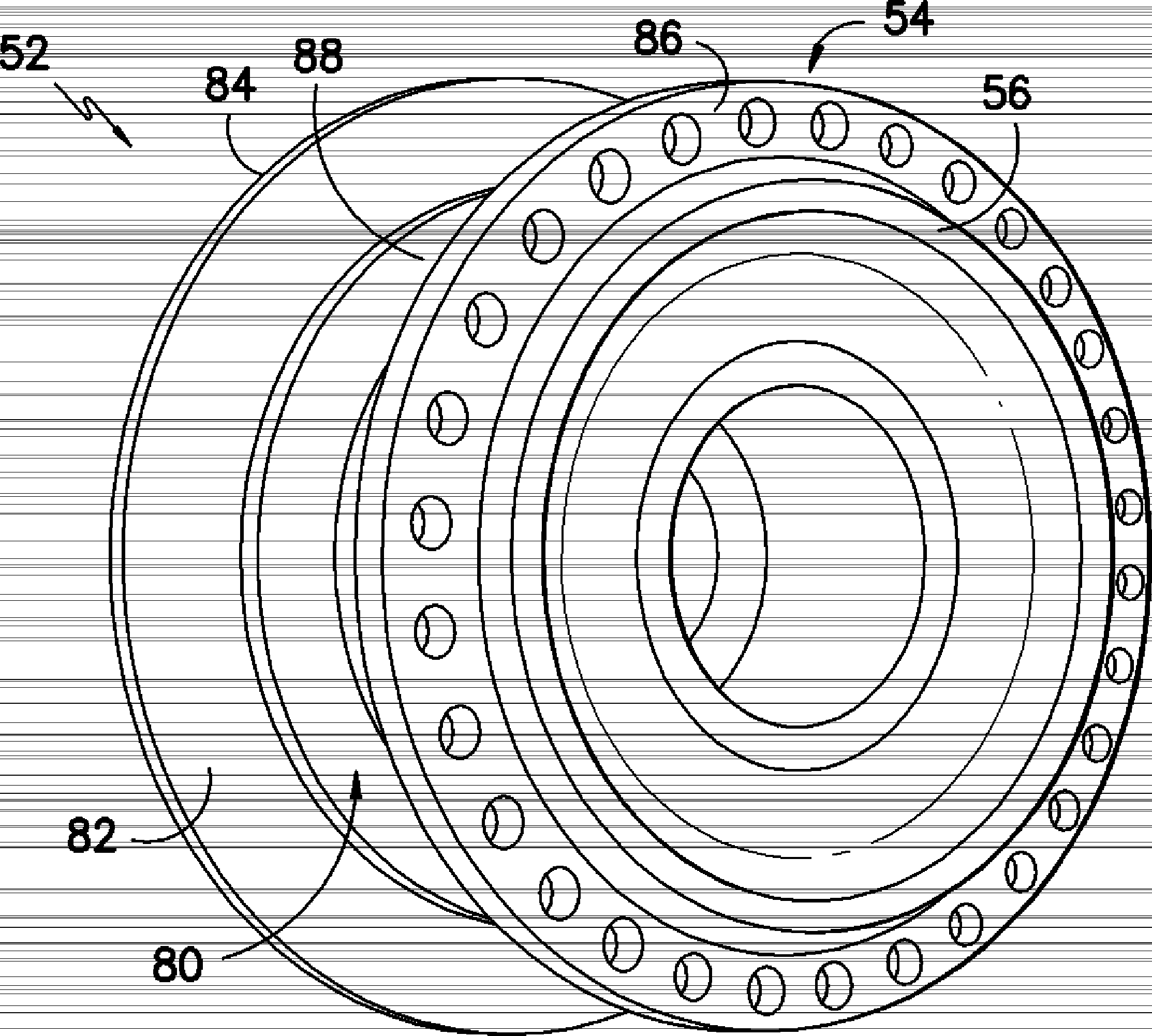

Modified rotor component and method for modifying a wear characteristic of a rotor component in a turbine system

A method for modifying a wear characteristic of a rotor component in a turbine system and a modified rotor component for a turbine system are disclosed. The method includes implanting ions of one of a Group 6 element, a Group 13 element, or a metalloid element through an exterior surface of a rotor component. The rotor component is one of a rotor wheel or a distance wheel.

Owner:GENERAL ELECTRIC CO

Storage device and storage unit

InactiveUS20170125672A1Improve retentionReducing random telegraph noiseSolid-state devicesDigital storageTe elementOxygen

Owner:SONY CORP

Coating liquid for forming n-type oxide semiconductor film, method for producing n-type oxide semiconductor film, and method for producing field-effect transistor

PendingUS20190051752A1Simple wayProduce uniformTransistorSemiconductor/solid-state device manufacturingSolventField-effect transistor

A coating liquid for forming an n-type oxide semiconductor film, the coating liquid including: a Group A element, which is at least one selected from the group consisting of Sc, Y, Ln, B, Al, and Ga; a Group B element, which is at least one of In and Tl; a Group C element, which is at least one selected from the group consisting of Group 4 elements, Group 5 elements, Group 6 elements, Group 7 elements, Group 8 elements, Group 9 elements, Group 10 elements, Group 14 elements, Group 15 elements, and Group 16 elements; and a solvent.

Owner:RICOH KK

Modified rotor component and method for modifying wear characteristic of rotor component

The invention relates to a modified rotor component and a method for modifying a wear characteristic of a rotor component. A method for modifying a wear characteristic of a rotor component in a turbine system and a modified rotor component for a turbine system are disclosed. The method includes implanting ions of one of a Group 6 element, a Group 13 element, or a metalloid element through an exterior surface of a rotor component. The rotor component is one of a rotor wheel or a distance wheel.

Owner:GENERAL ELECTRIC CO

Method of producing regenerated hydrotreating catalyst and method of producing petroleum products

ActiveUS9737881B2High activityMolecular sieve catalystsOther chemical processesXANES SpectroscopyPetroleum product

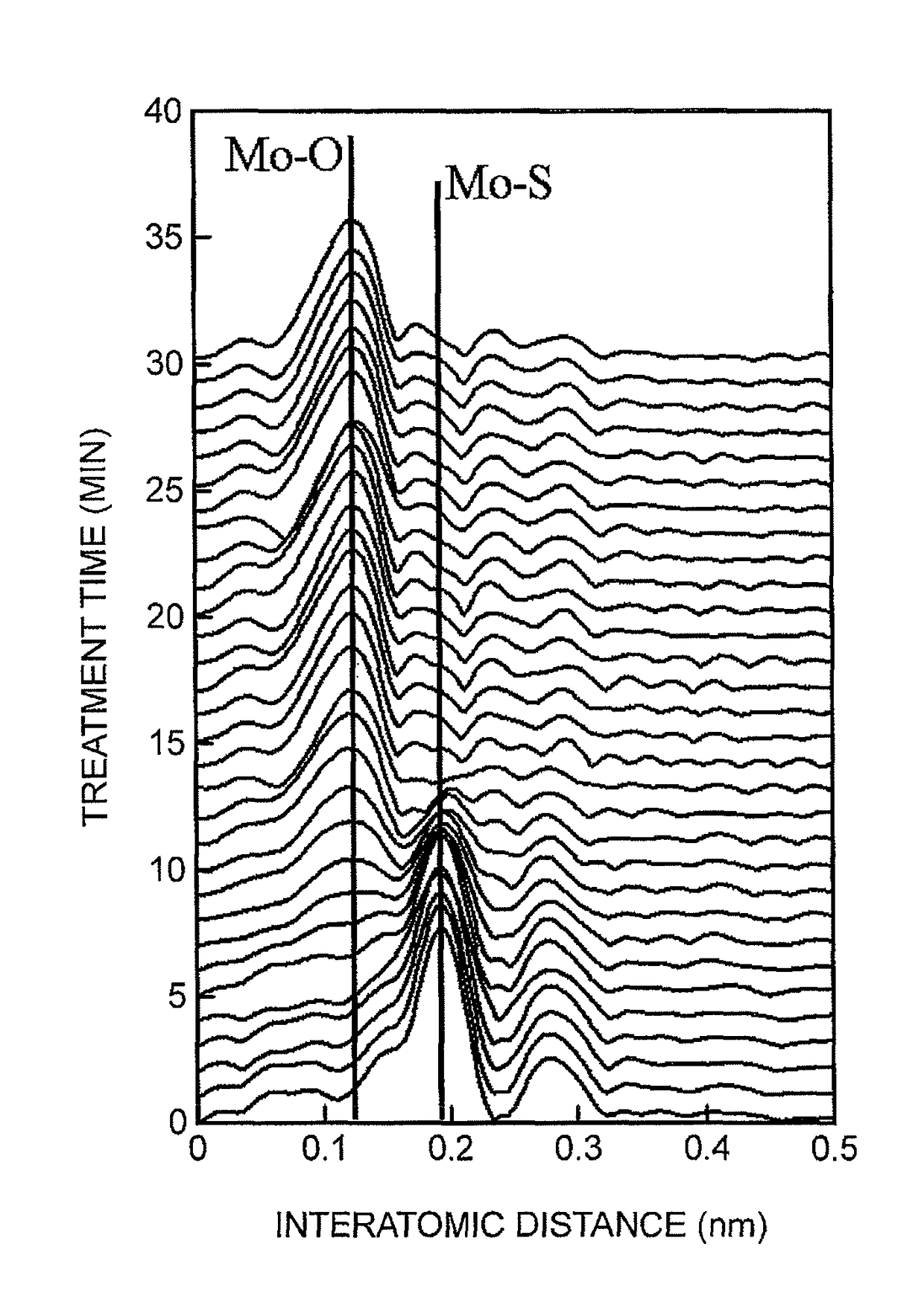

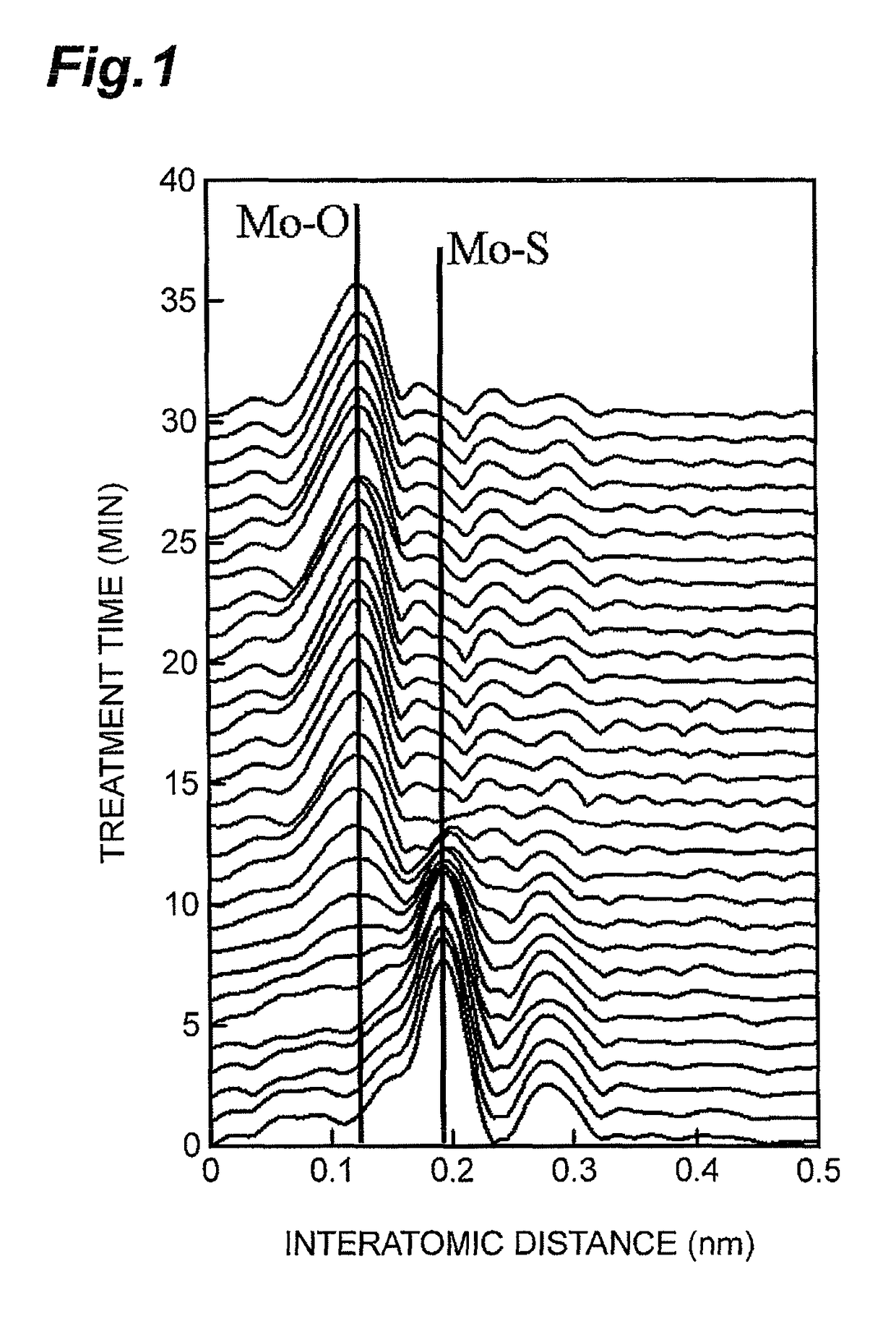

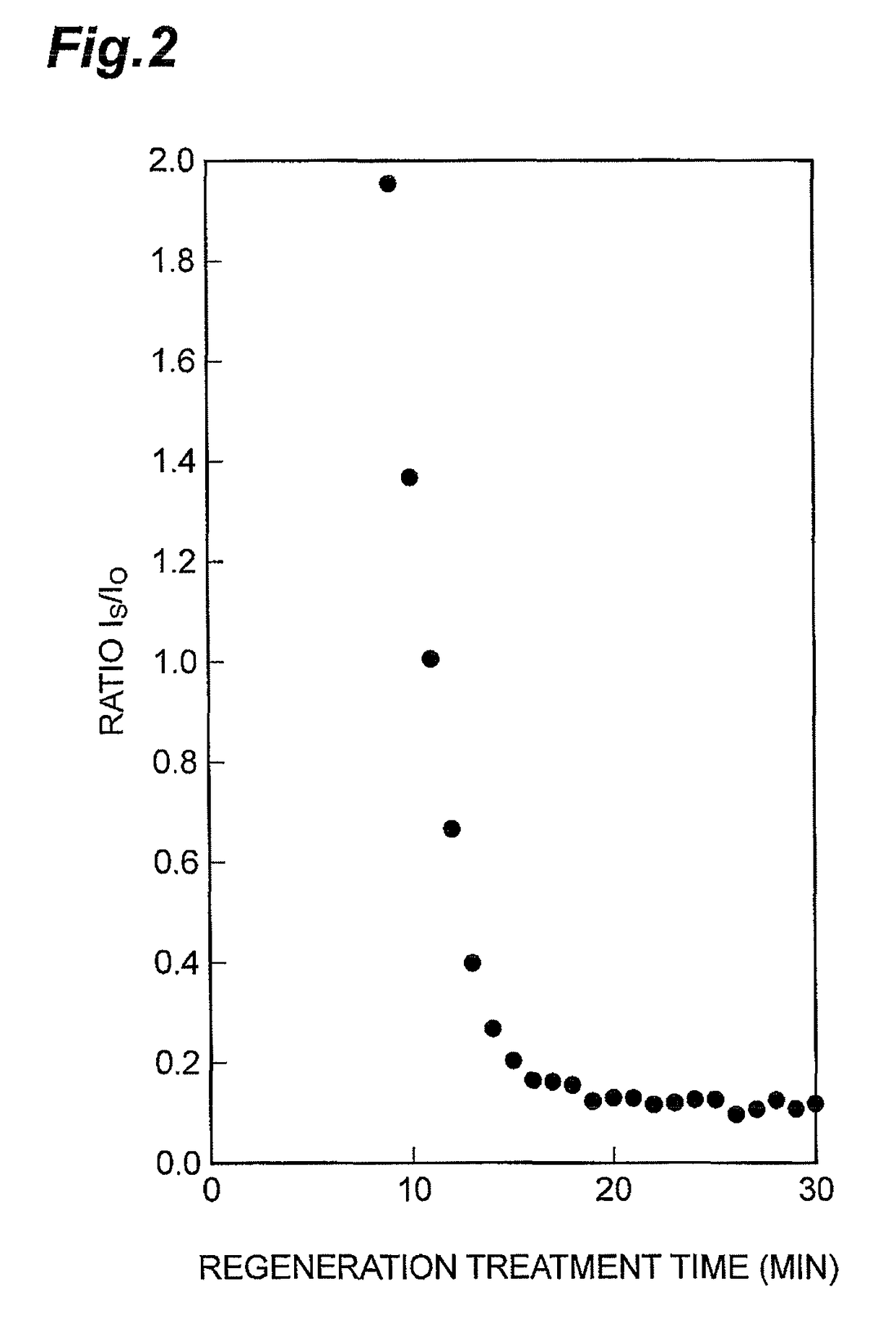

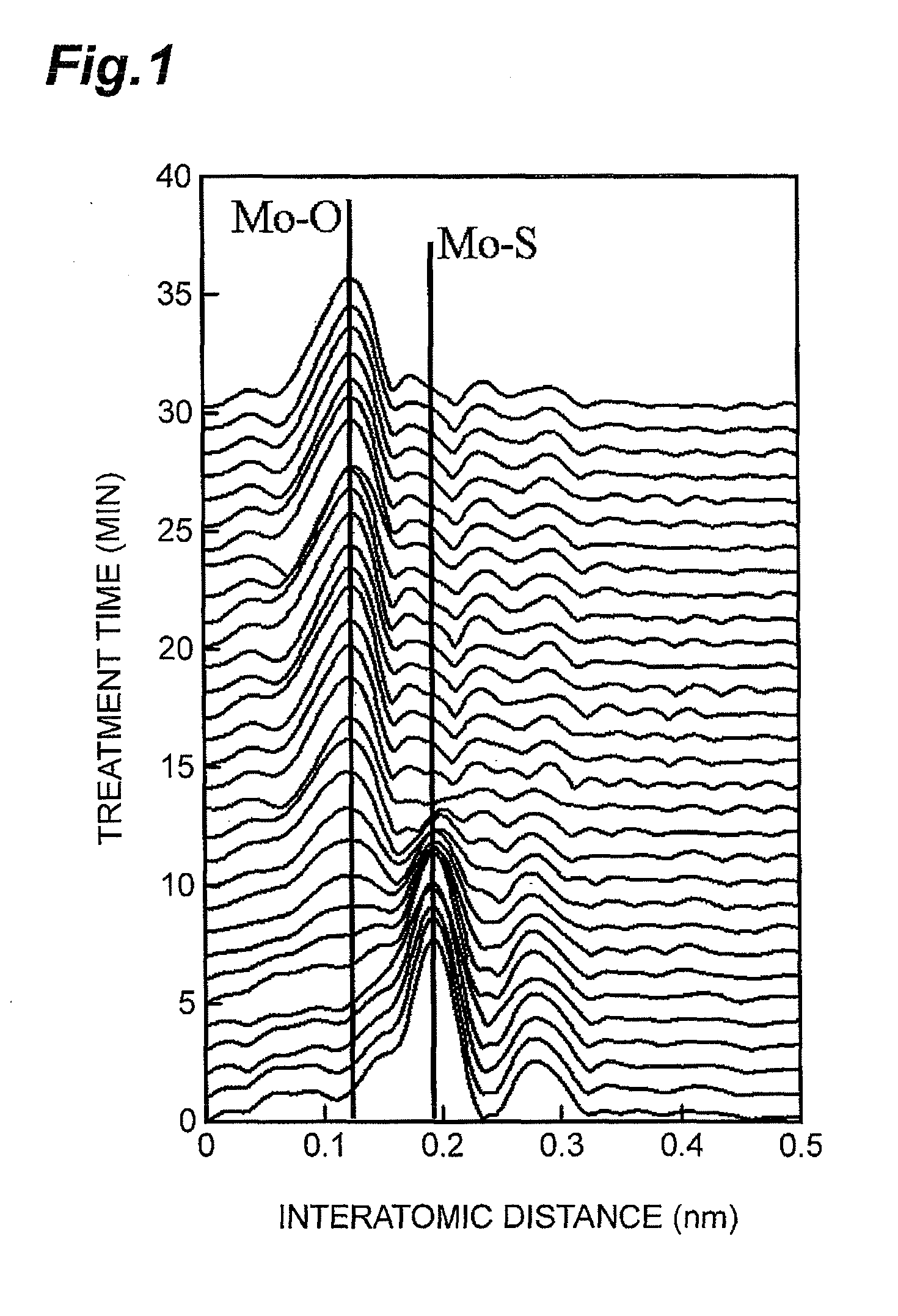

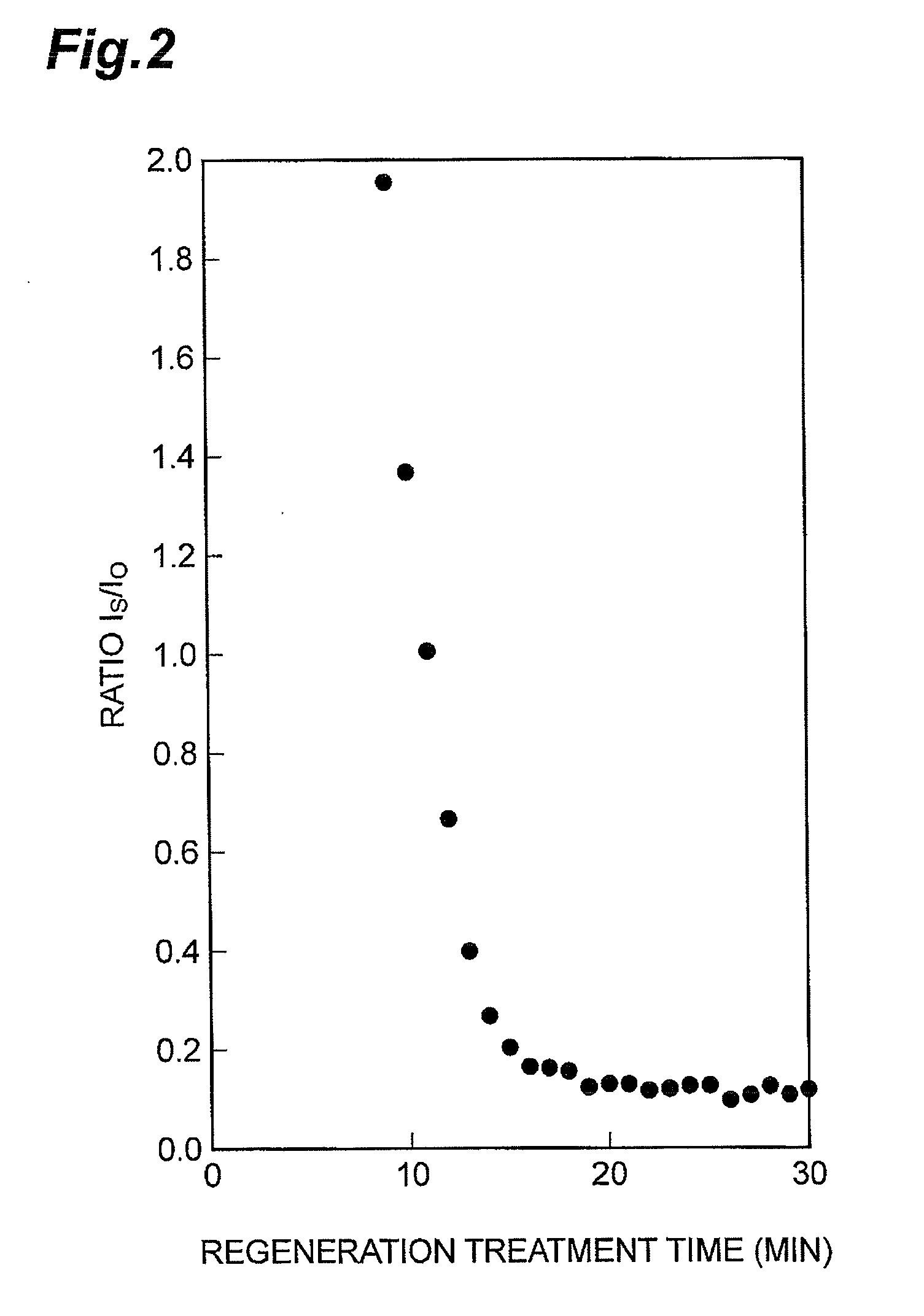

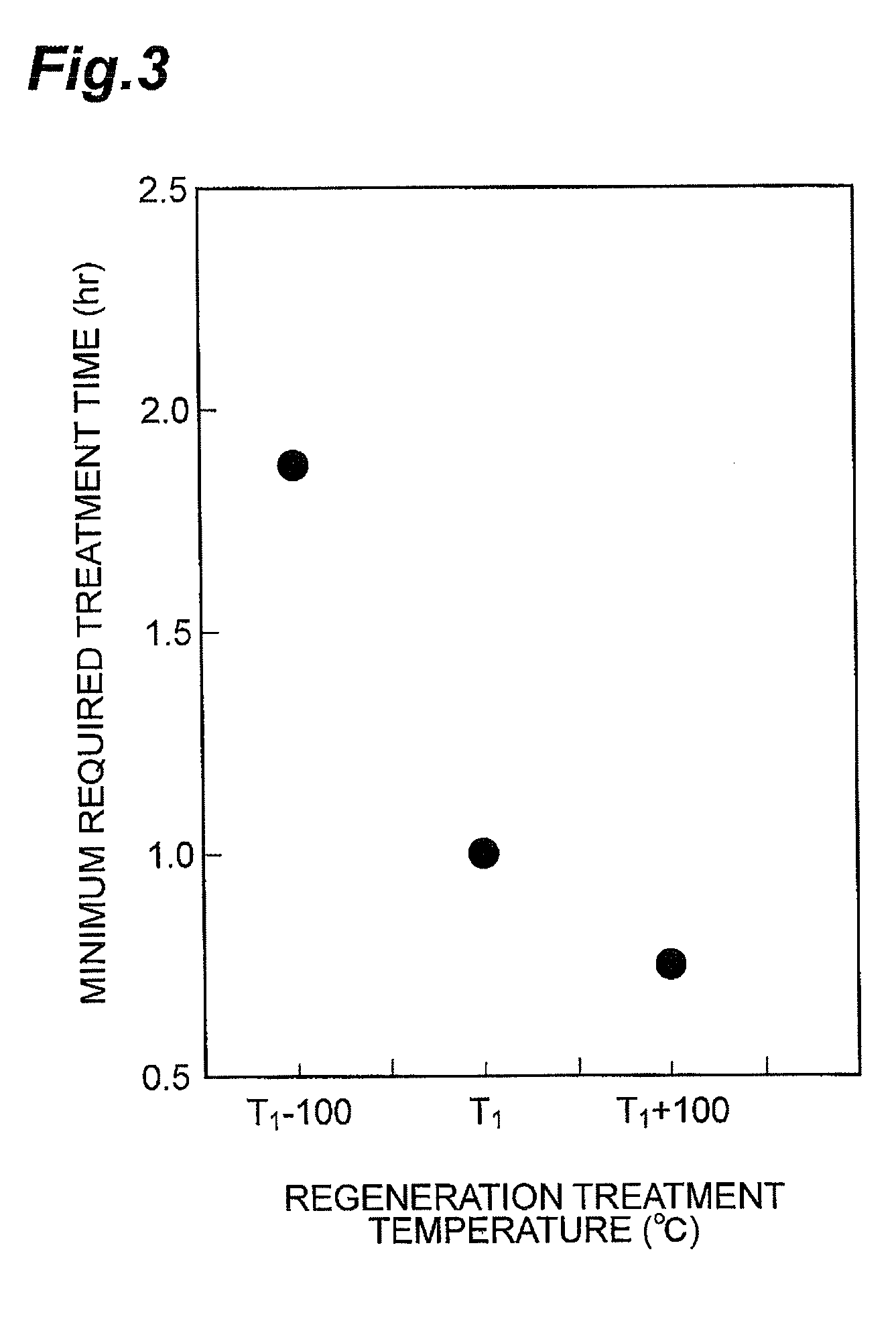

A method of producing a regenerated hydrotreating catalyst, including a first step of preparing a hydrotreating catalyst that has been used for hydrotreatment of a petroleum fraction and has a metal element selected from Group 6 elements of the periodic table; a second step of performing regeneration treatment for part of the catalyst prepared in the first step, then performing X-ray absorption fine structure analysis for the catalyst after the regeneration treatment, and obtaining regeneration treatment conditions in which a ratio IS / IO of a peak intensity IS of a peak attributed to a bond between the metal element and a sulfur atom to a peak intensity IO of a peak attributed to a bond between the metal element and an oxygen atom is in the range of 0.1 to 0.3 in a radial distribution curve obtained from an extended X-ray absorption fine structure spectrum.

Owner:JX NIPPON OIL & ENERGY CORP

Sintered compact, cutting tool formed using sintered compact, and method for manufacturing sintered compact

Owner:SUMITOMO ELECTRIC IND LTD

Positive electrode current collector for lithium ion secondary battery, positive electrode for lithium ion secondary battery, and positive electrode current collector for lithium ion secondary battery

InactiveCN102763253BEasy and reliableDissolution inhibitionElectrode carriers/collectorsSecondary cellsLithiumSurface layer

Disclosed is a positive electrode current collector for a lithium ion secondary battery, which is characterized by comprising an aluminum foil comprising pure aluminum or an aluminum alloy and a surface layer formed on one surface or both surfaces of the aluminum foil, wherein the surface layer contains C in an amount of 10 to 95 at.% and additionally contains at least one element selected from Group 4 to Group 6 elements in an amount of 5 to 90 at.%. Also disclosed is a positive electrode for a lithium ion secondary battery, which is characterized by having a positive electrode active material layer that covers the surface layer of the positive electrode current collector for a lithium ion secondary battery. It becomes possible to prevent the elution of the current collector into an electrolytic solution to improve the adhesion between the current collector and the active material in the interface therebetween and increase the service life of a battery.

Owner:KOBE STEEL LTD

Method of producing regenerated hydrotreating catalyst and method of producing petroleum products

ActiveUS20130233769A1High activityMolecular sieve catalystsOther chemical processesXANES SpectroscopyPetroleum product

A method of producing a regenerated hydrotreating catalyst, including a first step of preparing a hydrotreating catalyst that has been used for hydrotreatment of a petroleum fraction and has a metal element selected from Group 6 elements of the periodic table; a second step of performing regeneration treatment for part of the catalyst prepared in the first step, then performing X-ray absorption fine structure analysis for the catalyst after the regeneration treatment, and obtaining regeneration treatment conditions in which a ratio IS / IO of a peak intensity IS of a peak attributed to a bond between the metal element and a sulfur atom to a peak intensity IO of a peak attributed to a bond between the metal element and an oxygen atom is in the range of 0.1 to 0.3 in a radial distribution curve obtained from an extended X-ray absorption fine structure spectrum.

Owner:JX NIPPON OIL & ENERGY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com