Positive electrode current collector for lithium ion secondary battery, positive electrode for lithium ion secondary battery, and positive electrode current collector for lithium ion secondary battery

A positive current collector, secondary battery technology, applied in secondary batteries, electrode carriers/current collectors, battery electrodes, etc., can solve problems such as poor adhesion, reduced battery life, peeling, etc., to improve adhesion and battery life. Enhanced, easy and sure-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

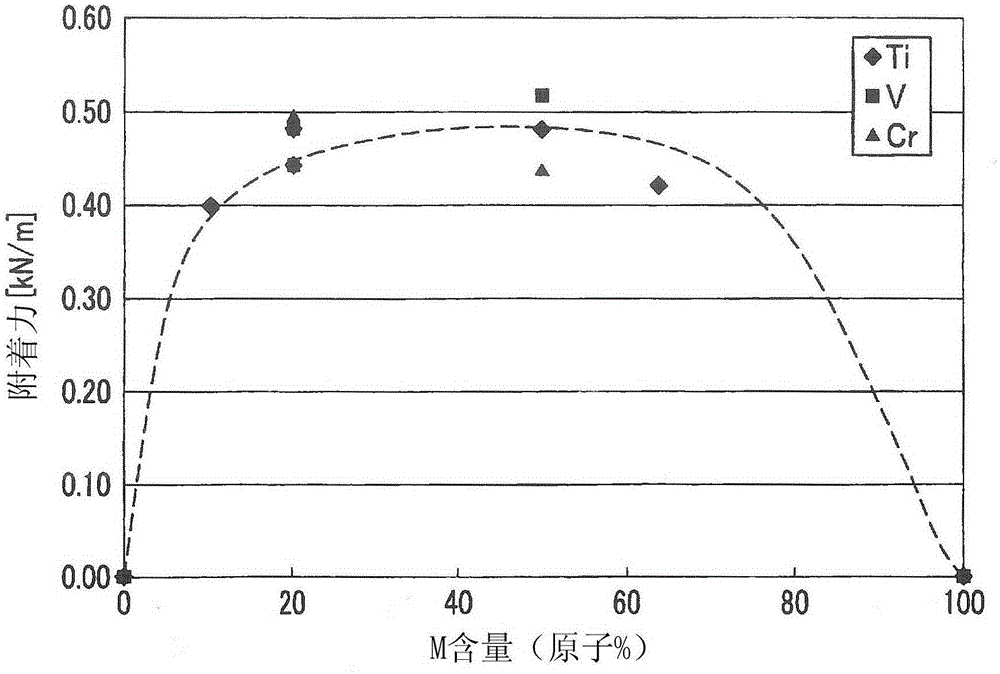

[0088] Next, an example of comparing the adhesion force at the interface between the current collector and the positive electrode active material layer will be shown with respect to a positive electrode satisfying the requirements of the present invention and a positive electrode not satisfying the requirements of the present invention. First, the positive electrode used in this example will be described along the manufacturing process. In addition, Comparative Example 4 of this embodiment assumes a positive electrode in which a carbon interlayer film is formed on a current collector made of a conductive material described in Patent Document 1 above.

[0089] (1) Aluminum foil manufacturing process

[0090] In the aluminum foil manufacturing process, the same treatment was performed in Examples 1-12 and Comparative Examples 1-10. That is, an aluminum plate was rolled to produce an aluminum foil having a length of 50 mm x a width of 50 mm x a thickness of 15 μm.

[0091] (2) ...

no. 2 example

[0108] Next, in order to investigate more preferable forms of the current collector and the positive electrode of the present invention, an example of comparing the wettability of the surface of the current collector will be shown. In addition, this characteristic is merely a desired characteristic of the present invention, so even if this characteristic is not satisfied, the minimum object of the present invention can be achieved if the adhesive force of the first embodiment is satisfied. In this example, using Examples 1-12 and Comparative Examples 1-3, 5-8 manufactured by the same manufacturing process as the said 1st Example, the following measurement and evaluation were performed.

[0109] (1) Measurement of the composition of the surface layer

[0110] After the aforementioned surface layer forming process, the composition of the surface layer was measured by AES.

[0111] (2) Measurement and evaluation of water contact angle

[0112] After the aforementioned surface l...

no. 3 example

[0120] Next, in order to investigate more preferable forms of the current collector and positive electrode of the present invention, examples of comparative corrosion resistance will be shown. In addition, this characteristic is merely a desired characteristic of the present invention, so even if this characteristic is not satisfied, the minimum object of the present invention can be achieved if the adhesive force of the first embodiment is satisfied. In this example, the following treatments were performed using Examples 3 to 5, 8, 9, and 13 and Comparative Examples 8 to 10 manufactured by the same manufacturing steps as in the first example described above.

[0121] (1) Measurement of the composition of the surface layer

[0122] After the aforementioned surface layer forming process, the composition of the surface layer was measured by AES.

[0123] (2) Evaluation of corrosion resistance

[0124] Using the positive electrode produced by the above method, a battery cell wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com