Method for determining blending amount of ashless coal and method for producing blast furnace coke

An ash-free coal and blending technology, applied in coke ovens, petroleum industry and other directions, can solve the problems of adhesion obstruction and low strength, and achieve the effect of reliable manufacturing, reducing manufacturing cost and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

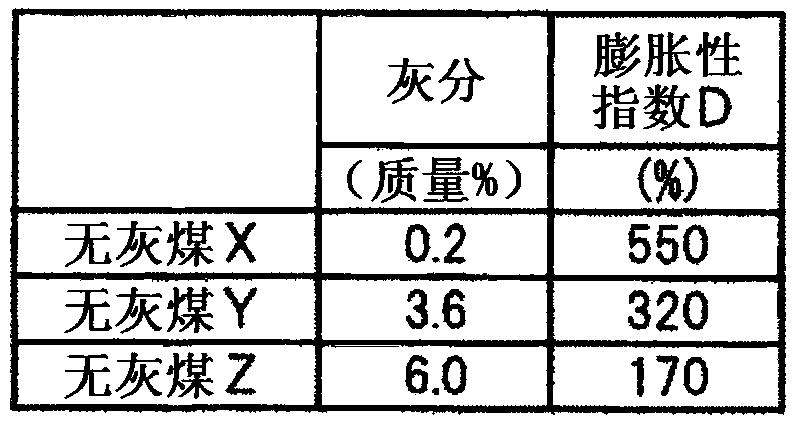

[0063] Using the ash-free coal X among the ash-free coals produced as described above, cokes for blast furnaces of Examples 1 to 5 were produced in the following procedure.

[0064] (blending process)

[0065] As the raw coal, various raw coals A to E having the characteristics shown in Table 2 were adjusted to a water content of 7.5% by mass, and mixed according to the blending ratio condition 1 shown in Table 2 on a dry coal basis. At this time, as the raw coal, the whole (100% by mass) of the raw coal was pulverized to a maximum diameter of 3 mm or less. In addition, the maximum fluidity MF [dppm] of raw coal and ash-free coal shown in Table 2 was measured by the Gieseler plastometer method in accordance with JIS-M8801:2004. In addition, the average maximum reflectance Ro [%] is measured in accordance with JIS-M8816:1992, and the expansion ratio [volume %] is measured in accordance with JIS-M8801:2004.

[0066] Make the packing bulk density of the raw coal be 740kg / m 3 T...

Embodiment 6~8

[0070] The ash-free coal used is the ash-free coal Y in Table 1. In addition, the same steps as in Examples 1 to 5 are used to blend the raw coal and the ash-free coal Y in the blending amount shown in Table 3. Coal was dry-distilled to obtain cokes for blast furnaces in Examples 6-8. The standard value W of the above raw material coal with respect to the ashless coal Y is 17.5% by mass.

Embodiment 9、10

[0072] The ash-free coal used is the ash-free coal Z in Table 1. Except for this, the same steps as in Examples 1 to 5 were used to blend raw coal and ash-free coal Z in the blending amount shown in Table 3. The mixed coal was subjected to dry distillation to obtain coke for blast furnaces in Examples 9 and 10. The reference value W of the raw material coal to the ash-free coal Z is 32.9% by mass.

[0073]

[0074] As the raw coal, various raw coals A to E with the characteristics shown in Table 2 were adjusted to have a water content of 7.5% by mass, and mixed according to the blending ratio condition 2 shown in Table 2 on a dry coal standard to prepare the raw coal . In this case, as the raw coal, the whole (100% by mass) of the raw coal was pulverized to a maximum diameter of 3 mm or less. Next, without mixing ash-free coal, the raw coal was dry-distilled under the same conditions as in Examples 1 to 5 to obtain coke for a blast furnace in Comparative Example 1.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com