Thin type fan

A thin fan and fan wheel technology, used in non-variable-capacity pumps, pump devices, machines/engines, etc., can solve problems such as reducing axial thickness, reduce axial thickness, increase starting balance and rotational stability , The effect of preventing axial detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above-mentioned purpose, technical features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are specifically cited below, and detailed descriptions are as follows in conjunction with the accompanying drawings:

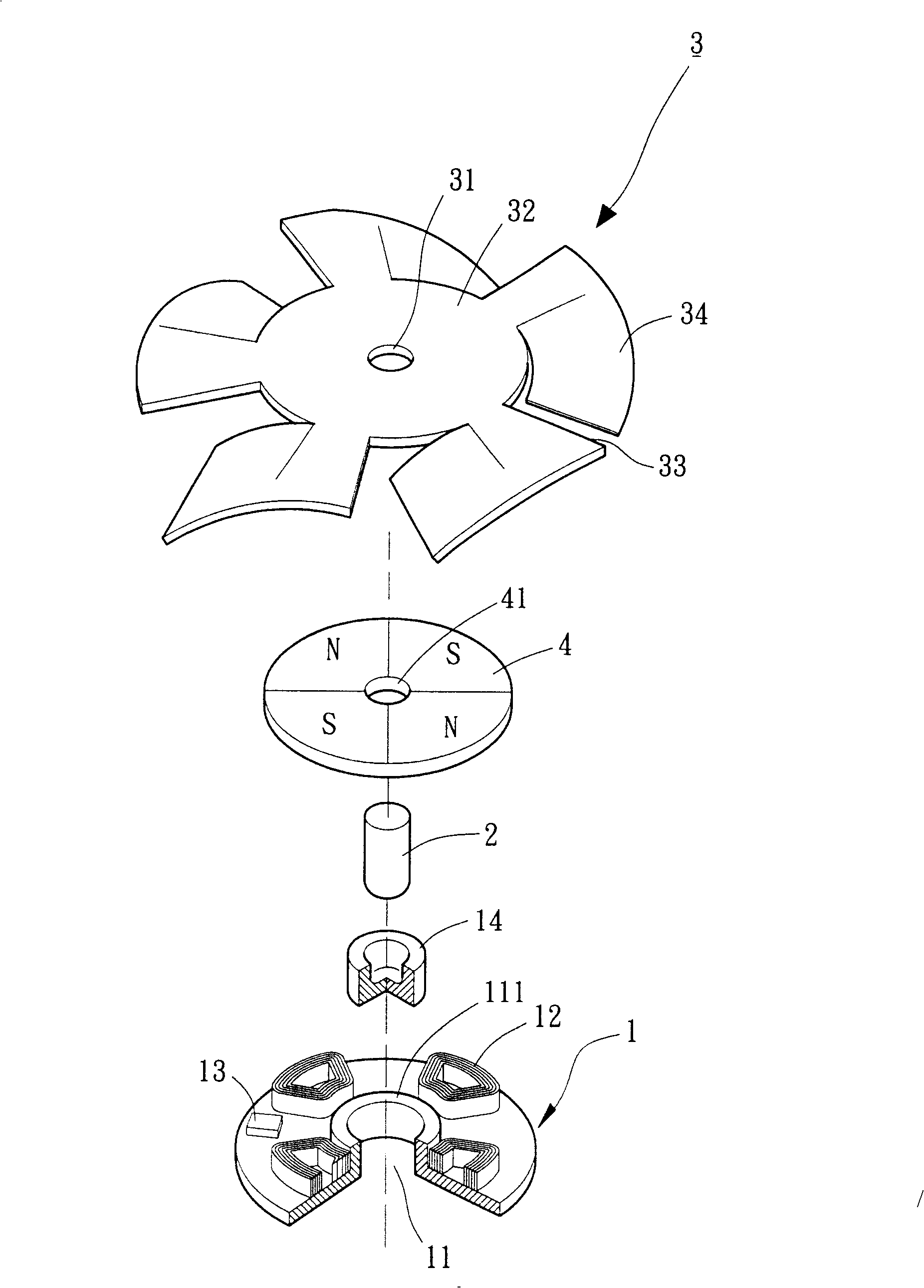

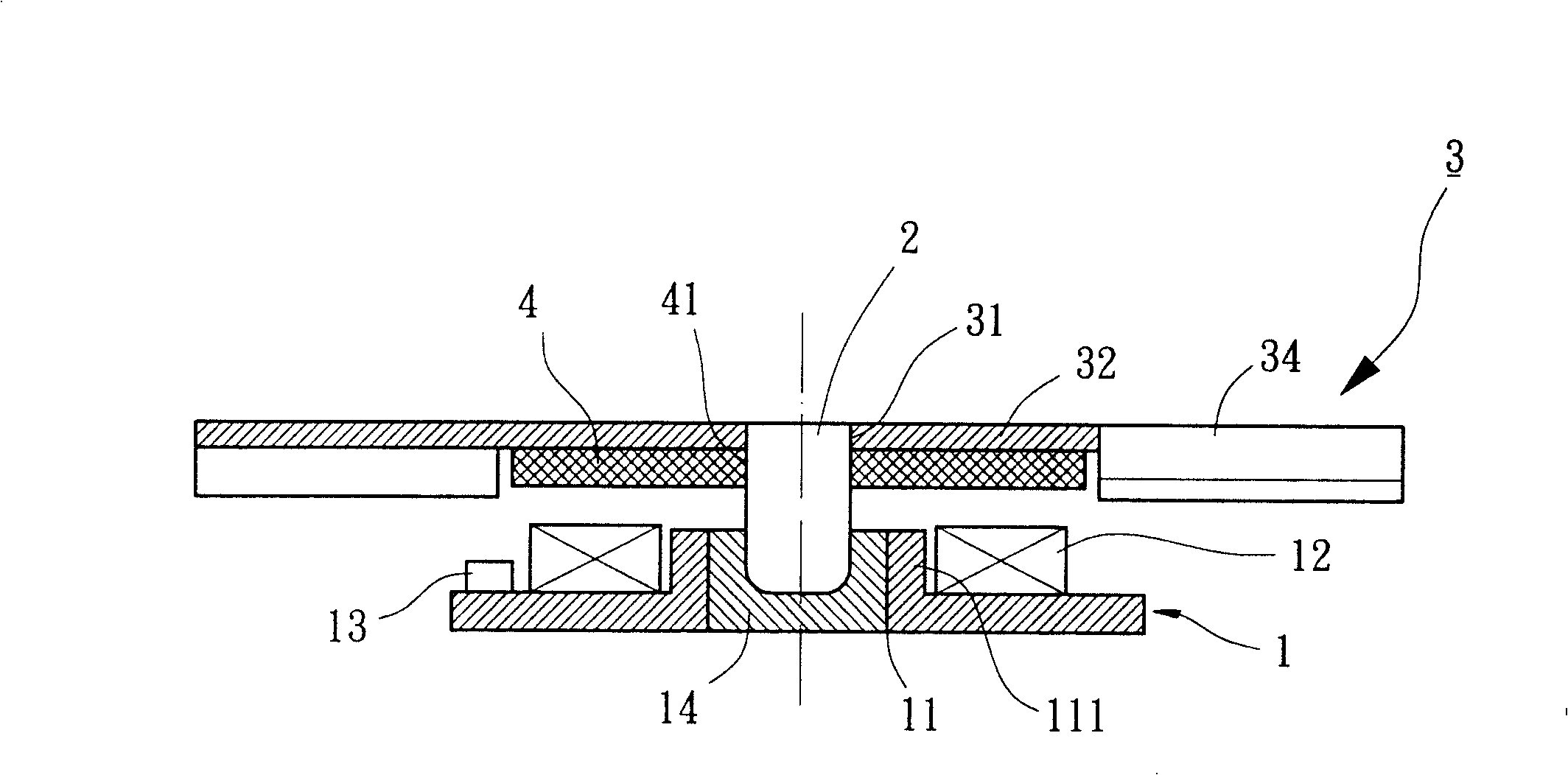

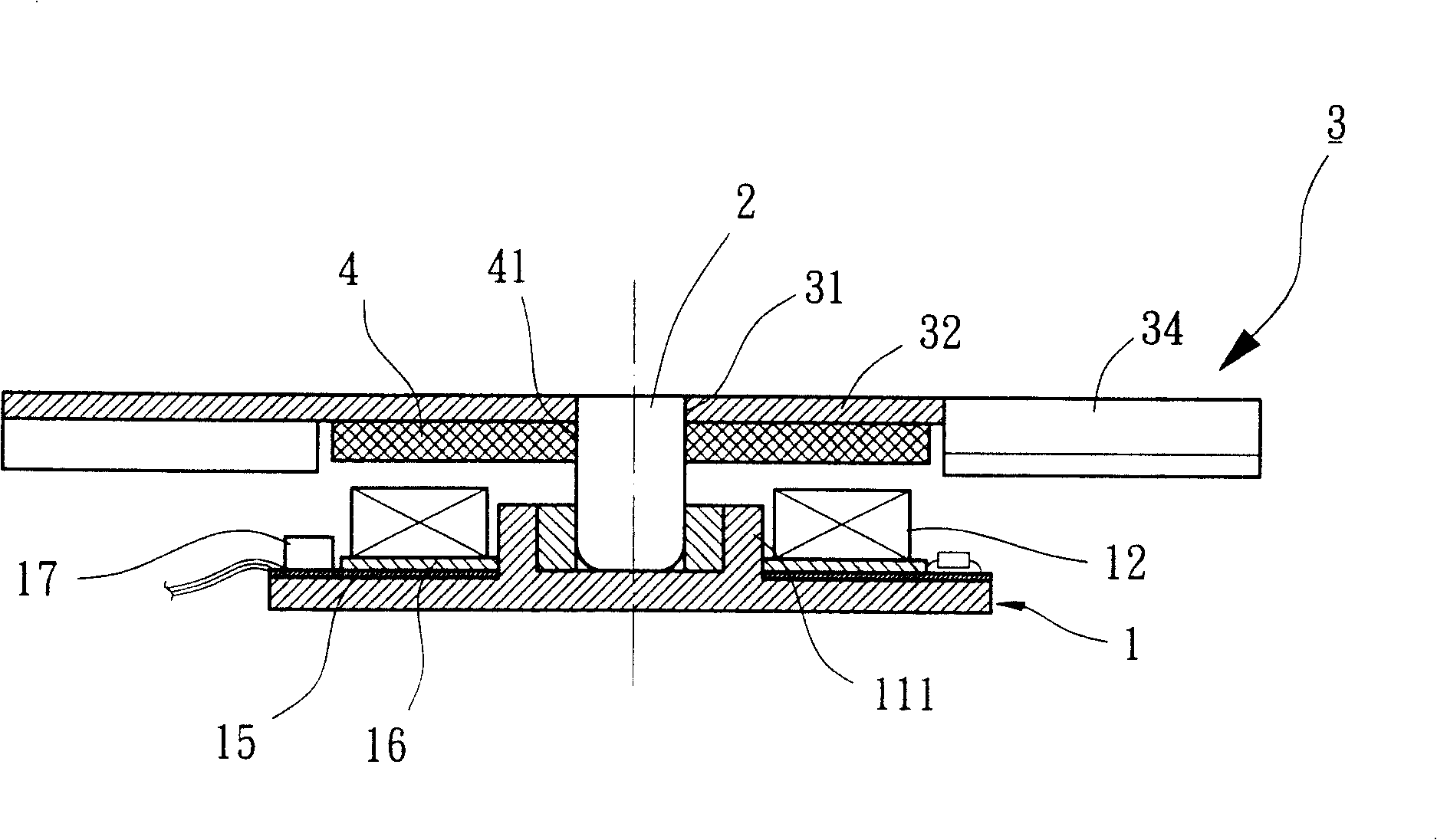

[0018] Please refer to figure 1 , 2 As shown, in the first embodiment of the present invention, a thin fan mainly includes: a base 1 , a shaft 2 , a fan wheel 3 and a sheet magnet 4 . The base 1 can be regarded as a stator component, and the shaft 2, fan wheel 3 and sheet magnet 4 can be regarded as a rotor component, and according to product requirements, the total axial thickness of the rotor component can even be reduced to less than 3 mm.

[0019] Please refer to figure 1 , 2 As shown, the base 1 is preferably made of magnetically permeable material, such as iron or iron alloy. The base 1 is provided with a shaft hole 11 , at least one coil 12 , a driving ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com