Rolled Copper Foil and Manufacturing Method of Rolled Copper Foil

a manufacturing method and technology of copper foil, applied in manufacturing tools, heat treatment equipment, printed circuit aspects, etc., can solve the problems of product failure, difficult control of working ratio per rolling pass, and material (copper foil) becoming harder due to hardness, etc., to improve flexible fatigue properties, excellent flexible fatigue properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

of the Present Invention

[0050](In-Plane Alignment Measurement)

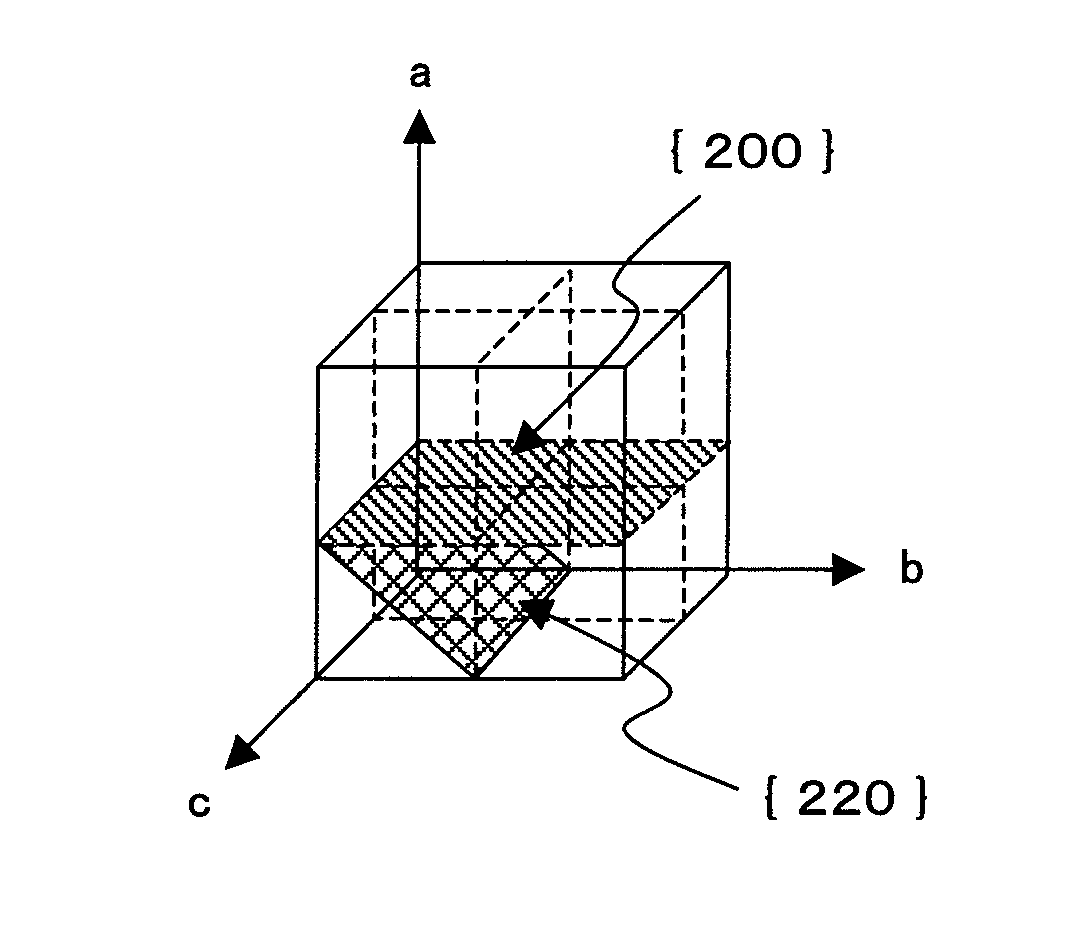

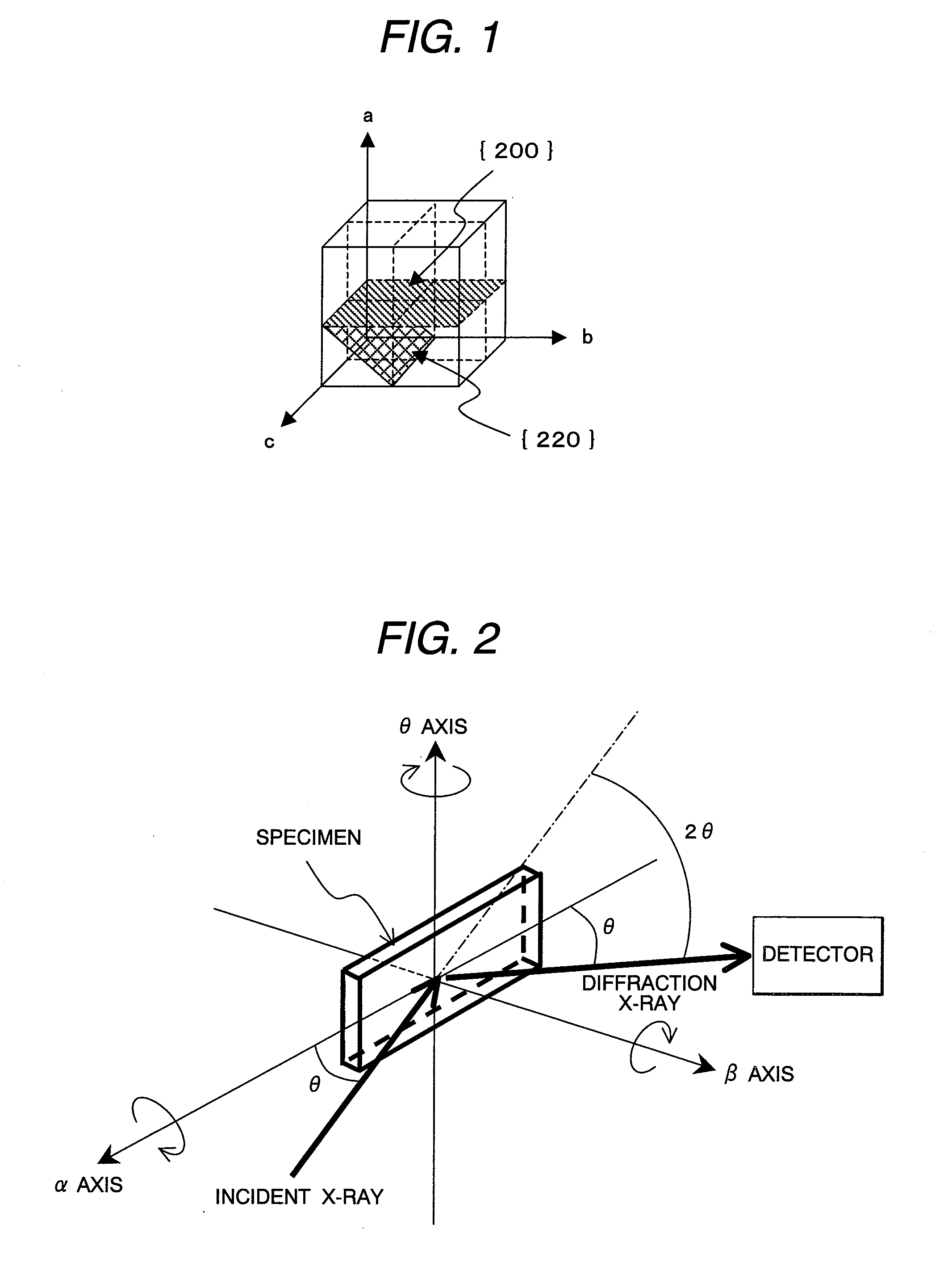

[0051]A rolled copper foil in this embodiment is the rolled copper foil after the final cold rolling step but before recrystallization annealing. In results obtained by the X-ray diffraction pole figure measurement with respect to the rolled surface, the rolled copper foil includes a group of crystal grains which exhibits four-fold symmetry, in which at least four peaks of a {220}Cu plane diffraction of a copper crystal due to the group of crystal grains exhibiting the four-fold symmetry, which is obtained by β axis scanning with an α angle set to 45°, appear at intervals of 90°±5° along the β angle. For example, when the rolling direction of the copper foil is set to 0° of β angle in the pole figure measurement, centers of the four-fold symmetric peaks are approximately 0° (360°), 90°, 180°, and 270° of β angle.

[0052]If the {220}Cu plane diffraction peaks do not exhibit four-fold symmetry at intervals of 90°±5° in the XR...

second embodiment

of the Present Invention

[0053](Normalized Intensity)

[0054]A rolled copper foil in this embodiment is also the rolled copper foil after the final cold rolling step but before recrystallization annealing. When normalized intensity of the {220}Cu plane diffractions of the copper crystal in results obtained by the XRD pole figure measurement with respect to the rolled surface by the β axis scanning at respective α angles are plotted on a vertical axis with the α angle on a horizontal axis, the maximum value P of the normalized intensity appears in a range of the α angle from 25° to 35°, the maximum value Q of the normalized intensity appears in the range of the α angle from 40° to 50°, the normalized intensity increases monotonically in the range of the α angle from 85° to 90°, and the maximum value P, the maximum value Q, and the normalized intensity R at the α angle of 90° have the relation of “Q≦P≦R”. If, in result obtained by the above XRD pole figure measurement, the normalized int...

third embodiment

of the Present Invention

[0061](2θ / θ Measurement)

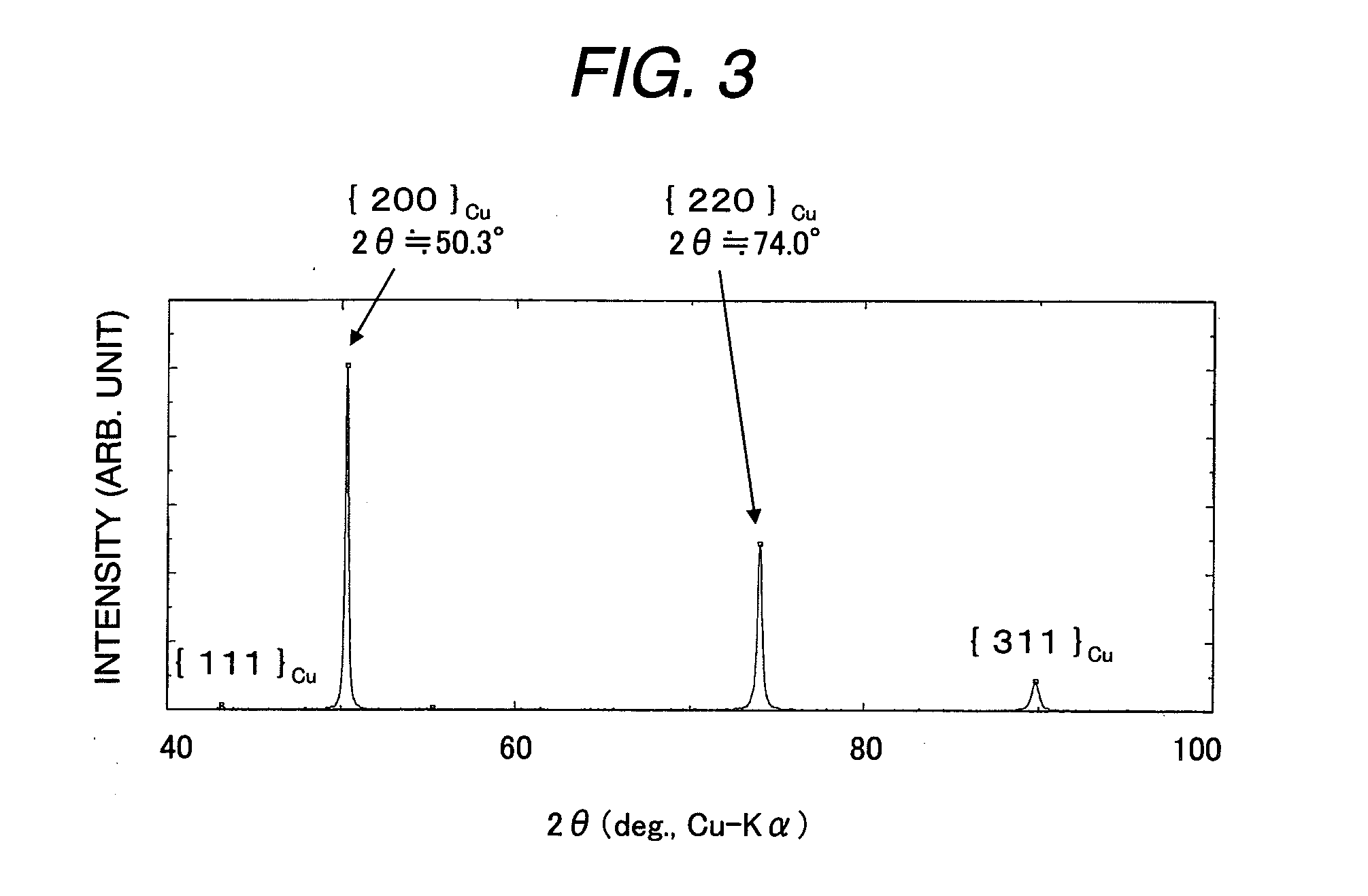

[0062]In results obtained by X-ray diffraction 2θ / θ measurement carried out for the rolled surface, a rolled copper foil after the final cold rolling step but before recrystallization annealing in this embodiment has a relation that diffraction peak intensity of the {200}Cu plane is equal to or greater than that of the {220}Cu plane (I{200}Cu≧I{220}Cu), where “I” means the intensity of a diffraction peak of the copper crystal.

[0063]As described before, when the rolled copper foil according to the present invention is in a state after the final cold rolling step has been applied and before recrystallization annealing is performed, the {200}Cu plane is aligned at the rolled surface of the copper foil. This means that the rolled surface of the copper foil includes a significant amount of crystal grains oriented to the {200}Cu plane. FIG. 3 is an example of a diffraction pattern by X-ray diffraction 2θ / θ measurement carried out for a rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com