High-strength-and ductility-product cold-rolled TRIP steel and preparing method thereof

A high-strength plastic product and cold-rolled steel strip technology, which is applied in the field of high-strength plastic product cold-rolled automotive steel, can solve problems such as unreasonable strength-plastic product matching, formability needs to be improved, and surface quality deterioration, so as to improve the surface quality , Improve the formability and impact absorption energy, and the effect of large elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

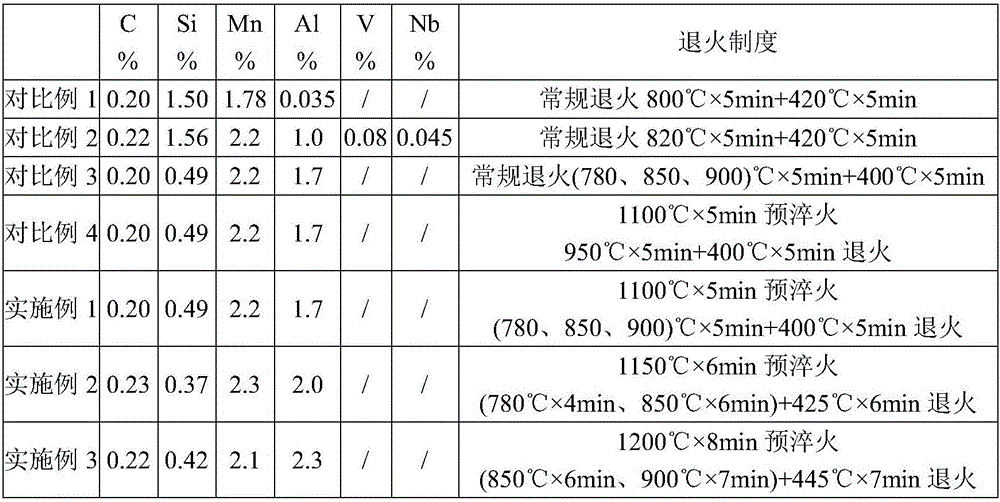

[0026] The invention provides a method for preparing high-strength plasticity cold-rolled TRIP steel. The percentages of the chemical components of the slab are C0.20-0.23%, Si 0.35-0.50%, Mn 2.0-2.4%, Alt 1.6-2.5%, P ≤0.01%, S ≤0.005%, and the rest are Fe and unavoidable impurities. The slab that meets this chemical composition is subjected to the following preparation steps:

[0027] 1) Forging, heating, hot-rolling, and water-cooling coiling of the billet to obtain a hot-rolled steel strip;

[0028] 2) pickling and cold-rolling the hot-rolled steel strip to make a cold-rolled steel strip;

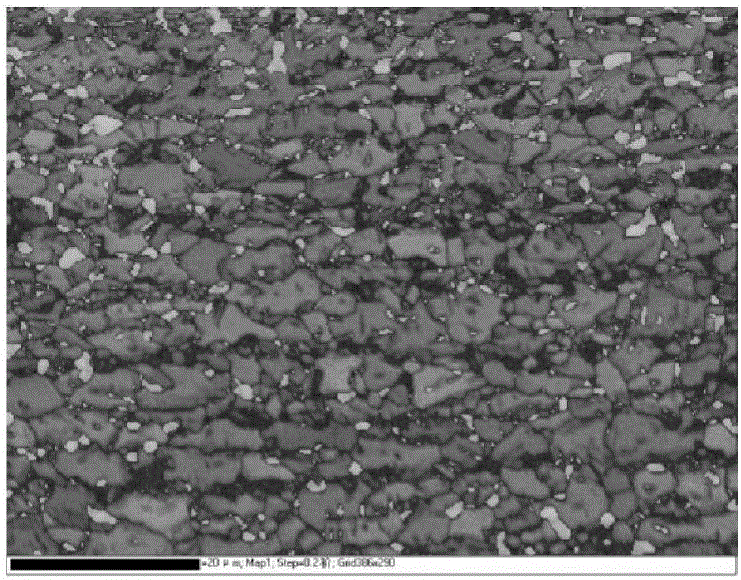

[0029] 3) Pre-quenching the cold-rolled steel strip, specifically: reheating the cold-rolled steel strip and keeping it warm for a certain period of time, and then water-quenching to room temperature to obtain a steel strip with a full martensitic structure;

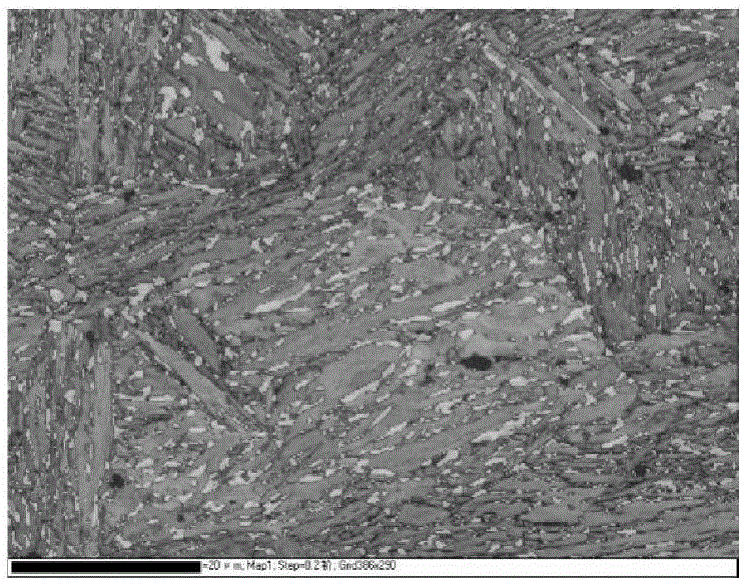

[0030] 4) Cleaning the quenched steel strip with full martensitic structure and then annealing it. After annealing, it is quickl...

Embodiment 1

[0049] The main chemical composition (mass percentage%) of the slab is shown in Table 1, and it also contains 0.006% P, 0.003% S, 0.004% N, and the rest is Fe and unavoidable impurities. The preparation steps are basically the same as those of Comparative Example 4, the only difference being that in the annealing step of Example 1, the steel strip at room temperature was heated to 780°C, 850°C, and 900°C, respectively. The mechanical properties of the finished steel strips are shown in Table 2.

Embodiment 2

[0051] The main chemical composition (mass percentage%) of the slab is shown in Table 1, and it also contains 0.005% P, 0.004% S, 0.002% N, and the rest is Fe and unavoidable impurities. The preparation steps adopt the same hot-rolling and cold-rolling steps as Comparative Example 1 to obtain a cold-rolled steel strip; then reheat the cold-rolled steel strip to 1150° C., keep it warm for 6 minutes, and then water-quench to room temperature; The strips were heated to 780°C and 850°C respectively, and held for 4 minutes and 6 minutes respectively, and then rapidly cooled to 425°C and held for 6 minutes respectively to obtain finished steel strips. Its mechanical properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com