Production process for shock-proof disaster-relieving hot rolled transformation-induced plasticity (TRIP) steel plates

A production process and steel plate technology, which is applied in the field of iron and steel metallurgy and rolling, can solve the problems of high steel strength and low plasticity, and achieve the effects of stable austenite, short production process, and refined grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below by embodiment the present invention will be further described.

[0014] A production process of hot-rolled TRIP steel plate for earthquake resistance and disaster resistance, comprising the following process steps:

[0015] ①Steelmaking and continuous casting process, control the chemical composition mass percentage of steelmaking: 0.10--0.40%C, 0.1--2.0%Si, 1.0-2.0%Mn, P≤0.013%, S≤0.013%, 0.01- -0.1%Al, 0.01--0.05%Nb, 0.1--0.2%Mo, the rest is Fe and unavoidable impurity elements; drawn into continuous casting slabs by continuous casting;

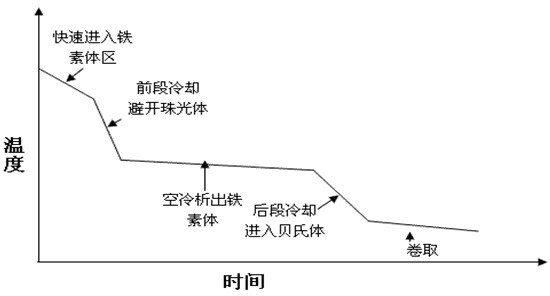

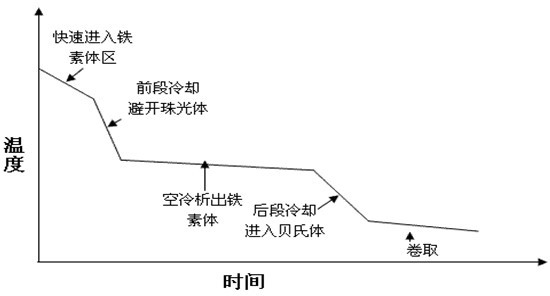

[0016] ②Heating and hot rolling process, the continuous casting slab with the above chemical composition is heated, the heating temperature is 1150--1200 ℃, the holding time is 50--180min, and the hot rolling method is used for production, and the hot rolling finish rolling start temperature is 980- -1100°C, finishing rolling temperature 820--870°C, finishing rolling total reduction rate 70--80%; strip exiting finishing rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com