Ultrahigh strength TRIP steel with pressure intensity being 1.5GPa or higher and preparation method thereof

An ultra-high-strength, ultra-cryogenic technology, which is applied in the field of ultra-high-strength TRIP steel and its preparation, can solve the problems of wasting energy, low tensile strength, and increasing production costs, so as to reduce costs and manufacturing difficulties, reduce casting difficulties, The effect of increasing the difficulty of casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] As a preferred embodiment, the chemical composition and content of an ultra-high-strength TRIP steel are: C is 0.1-0.25wt.%, Mn is 5-10wt.%, Si is 1-3wt.%, and P is ≤ 0.2wt.%, S is ≤0.005wt.%, and the balance is Fe and unavoidable impurities; the preparation method of the ultra-high-strength TRIP steel comprises the following steps:

[0045] (1) Melting: Melting and casting at a temperature of 1500-1700°C;

[0046] (2) Forging: Heat the ingot to 1150-1250°C, keep it warm for 1-2 hours, forge it into a long strip, and perform normalizing treatment (normalizing treatment to eliminate the internal stress generated by forging);

[0047] (3) Hot rolling: Cut the strip-shaped forging into a square ingot (80mm×80mm×40mm), heat it to 1100-1200°C, keep it warm for 2-3 hours, and perform multi-pass hot rolling (the total deformation is about 75-40mm). 95%), quenched, made into steel plate

[0048] Among them, the hot rolling adopts a two-roll hot rolling mill, and the deformati...

Embodiment 1

[0053] The chemical composition and content of the ultra-high-strength TRIP steel plate in this embodiment are: C is 0.21wt.%, Mn is 8.95wt.%, Si is 2.81%, P is ≤0.2wt.%, and S is ≤0.005wt.%. , the balance being Fe and unavoidable impurities.

[0054] The production method of the ultra-high-strength TRIP steel plate of the present embodiment is as follows:

[0055] (1) Melting: chemical composition and ingredients, melting at 1650°C, casting;

[0056] (2) Forging: heat the ingot to 1200°C, keep it warm for 2 hours, forge it into a long strip, and perform normalizing treatment;

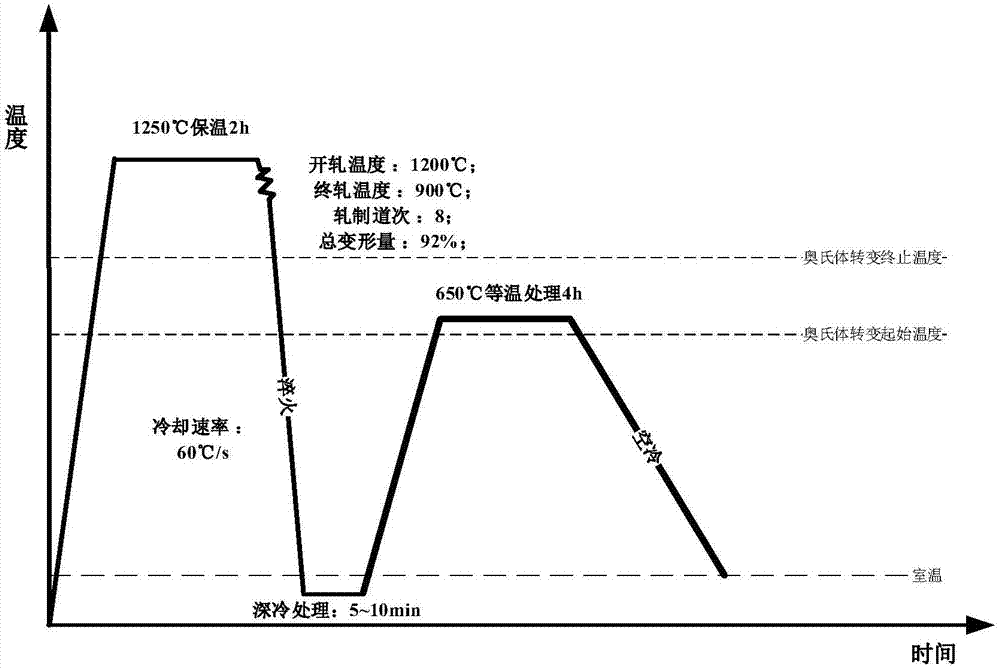

[0057] (3) Rolling: Cut the strip-shaped forging into a square ingot (80mm×80mm×40mm), heat it to 1250°C, keep it warm for 2h, and perform 8 passes of hot rolling (the total deformation is about 92%), and start rolling The temperature is 1200°C, the final rolling temperature is 900°C, post-quenching, the quenching adopts TMCP process, and the cooling rate is 60°C / s to make a 3.0mm thick hot-rolled st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com