High-surface-quality hot-galvanized transformation induced plasticity (TRIP) steel plate and manufacturing method thereof

A manufacturing method, hot-dip galvanizing technology, applied in the direction of manufacturing tools, hot-dip galvanizing process, heat treatment furnace, etc., can solve the problems of unfavorable widespread promotion and market competition, poor surface coating, poor coating of galvanized finished products, etc., and achieve a good market Demand and application prospects, good cold formability, good effect of coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

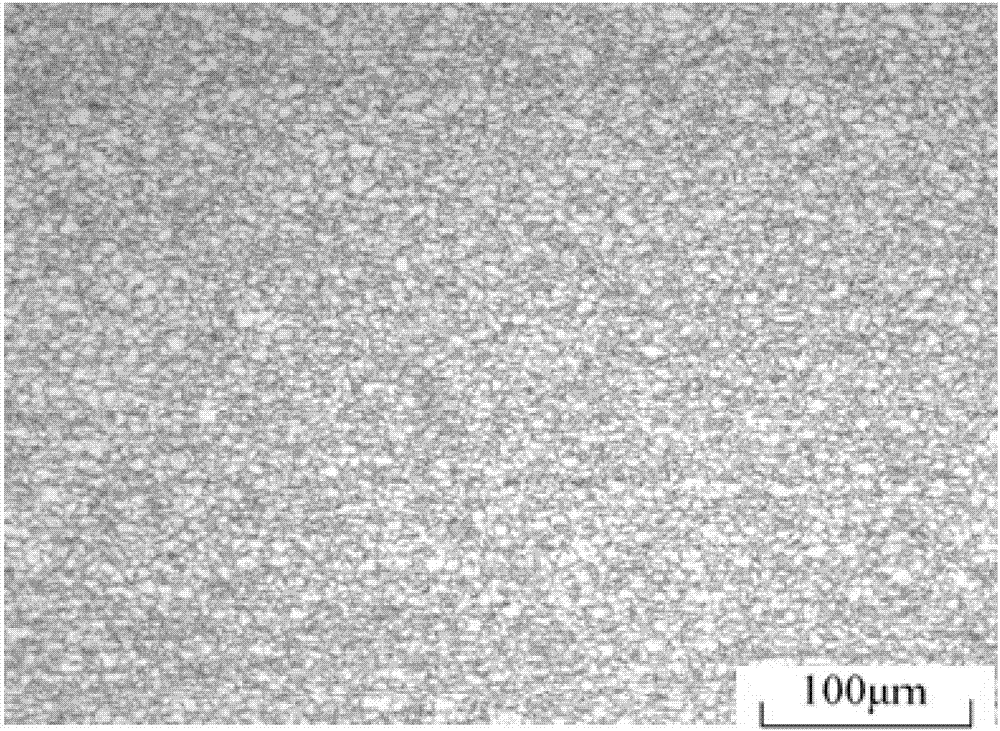

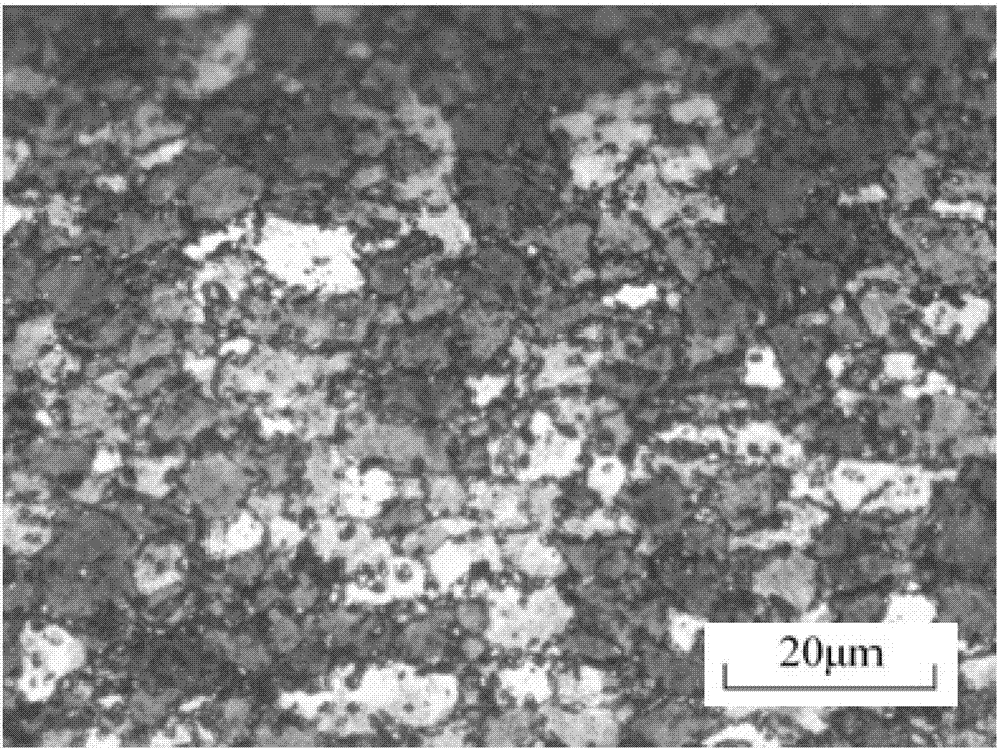

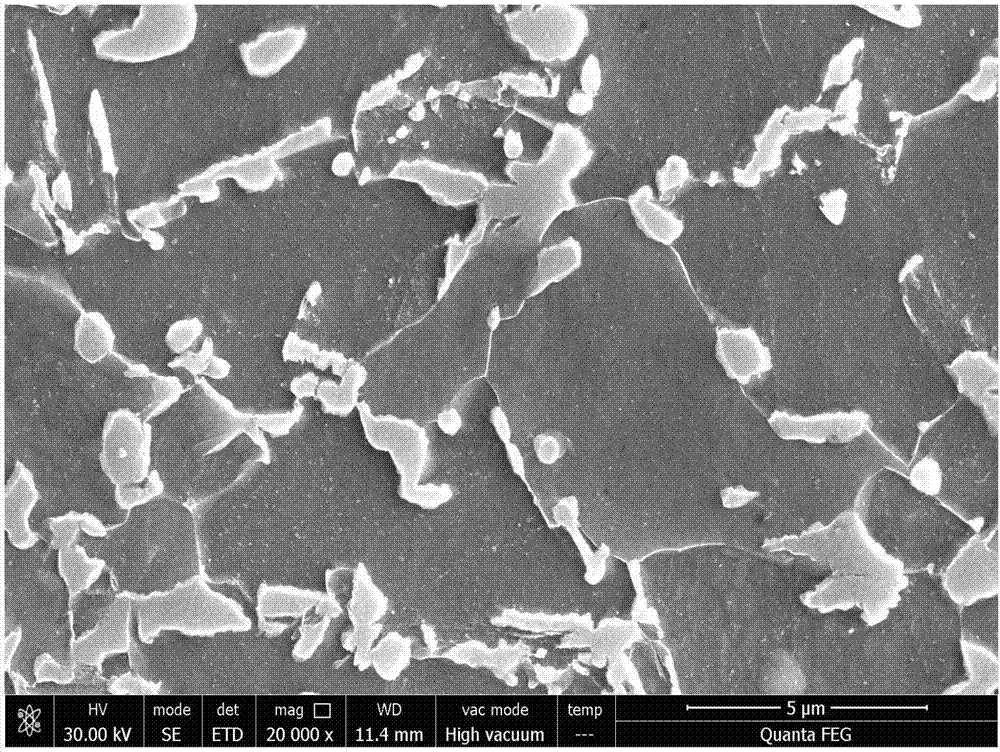

Image

Examples

Embodiment 1

[0061] A hot-dip galvanized TRIP steel sheet with high surface quality, its chemical composition and weight percentage are: C 0.14%, Mn 1.4%, P 0.020%, S 0.005%, Als 1.50%, and the balance is Fe and unavoidable impurities.

[0062] The manufacturing method of above-mentioned high surface quality hot-dip galvanized TRIP steel plate comprises the following steps:

[0063] (1) Continuous casting and steelmaking;

[0064] After the molten iron is desulfurized by KR, the target S content is 0.005%; LF furnace refining strengthens the control of C, Mn, Als, and P content in the steel; the target temperature of the continuous casting ladle is controlled at 20°C above the liquidus temperature. Dynamic light reduction is used to reduce or eliminate center porosity and center segregation defects.

[0065] (2) hot rolling;

[0066] The casting billet temperature is controlled at 1230°C, and the holding time is 3.0h; the hot rolling finishing temperature is controlled at 880°C; the hot ...

Embodiment 2

[0078] A hot-dip galvanized TRIP steel sheet with high surface quality, its chemical composition and weight percentage are: C 0.12%, Mn 1.60%, P 0.010%, S 0.003%, Als 2.0%, and the balance is Fe and unavoidable impurities.

[0079] The manufacturing method of above-mentioned high surface quality hot-dip galvanized TRIP steel plate comprises the following steps:

[0080] (1) Continuous casting and steelmaking;

[0081] After the molten iron is desulfurized by KR, the target S content is 0.003%; LF furnace refining strengthens the control of C, Mn, Als, and P content in the steel; the target temperature of the continuous casting process is controlled at 25°C above the liquidus temperature. Dynamic light reduction is used to reduce or eliminate center porosity and center segregation defects.

[0082] (2) hot rolling;

[0083] The casting billet temperature is controlled at 1250°C, and the holding time is 2.5h; the hot rolling finishing temperature is controlled at 900°C; the ho...

Embodiment 3

[0094] A hot-dip galvanized TRIP steel sheet with high surface quality, its chemical composition and weight percentage are: C 0.10%, Mn 1.20%, P 0.025%, S 0.004%, Als 1.80%, and the balance is Fe and unavoidable impurities.

[0095] The manufacturing method of above-mentioned high surface quality hot-dip galvanized TRIP steel plate comprises the following steps:

[0096] (1) Continuous casting and steelmaking;

[0097]After the molten iron is desulfurized by KR, the target S content is 0.004%; LF furnace refining strengthens the control of C, Mn, Als, and P content in the steel; the target temperature of the continuous casting ladle is controlled at 17°C above the liquidus temperature. Dynamic light reduction is used to reduce or eliminate center porosity and center segregation defects.

[0098] (2) hot rolling;

[0099] The casting billet temperature is controlled at 1215°C, and the holding time is 3.5h; the hot rolling finishing temperature is controlled at 860°C; the hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com