TRIP steel sheet for high strength cold rolled continuous annealing and preparation method thereof

A high-strength, steel plate technology, applied in the field of high-strength cold-rolled steel, can solve the problems of not much and less TRIP steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The manufacture method of 1000MPa level cold rolling continuous annealing TRIP steel of the present invention:

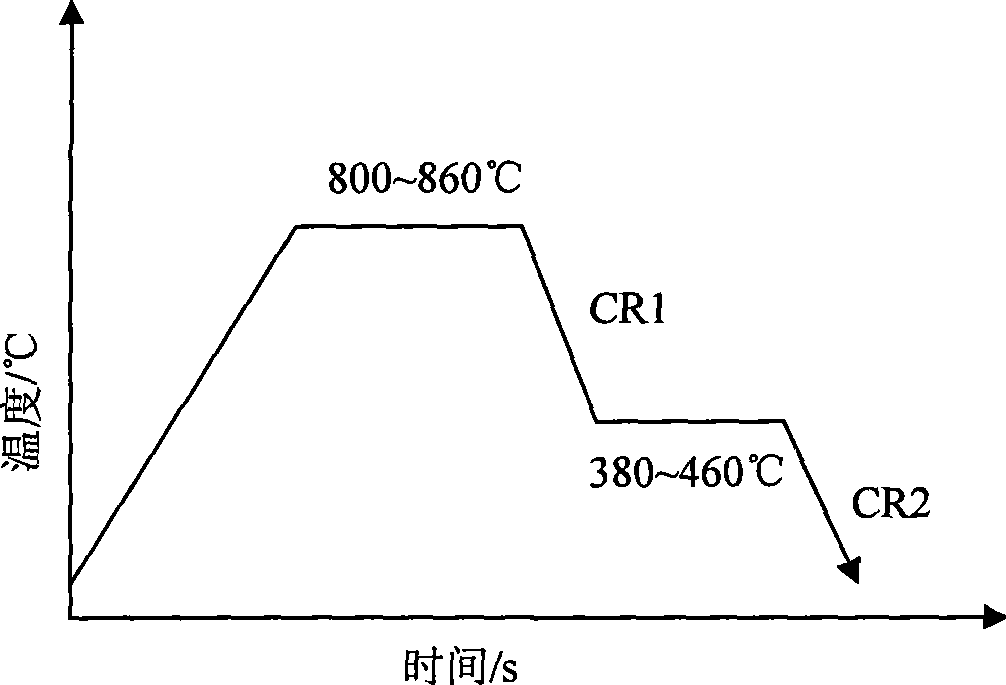

[0028] Firstly, the smelting is carried out according to the design composition. After the billet is forged, it is hot-rolled into a thin plate. The finishing temperature of hot rolling is 860°C, and the coiling temperature is 650°C; The phase zone annealing time is 120s or 180s, the cooling rate CR1 from the annealing temperature to the isothermal temperature is greater than 20°C / s; the isothermal temperatures are 380, 420 and 460°C, the isothermal time is 240s, and the cooling rate CR2 after isothermal is greater than 20 °C / s to cool to room temperature, so as to obtain 1000MPa grade cold-rolled TRIP steel for continuous annealing. figure 1 For the annealing process, Table 1 is the chemical composition, and Table 2 is the mechanical properties.

[0029] Table 1 chemical composition

[0030] C Si mn P S Cu Ni Nb Ti 0.24 1.40 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com