High-strength plastic accumulation TRIP (Transformation-Induced Plasticity) steel plate and preparation method thereof

A high-strength plastic product, steel plate technology, applied in the field of automobile steel manufacturing, can solve the problems of low crimping temperature, high price, complicated process, etc., and achieve the effects of excellent performance, wide application range and simple preparation method.

Inactive Publication Date: 2013-02-06

ANGANG STEEL CO LTD

View PDF5 Cites 96 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage is that the strength and plasticity of DP steel and TRIP steel are about 20GPa%, which is difficult to meet the ever-increasing energy-saving, safety and environmental protection standards of the automobile industry.

The disadvantage is that the manganese content is high, between 15 and 24%, the cost is high, and the price is expensive

[0006] As one of the third-generation advanced high-strength steels, QP steel has good strength and plasticity. The disadvantage is that the process is complex and requires a special continuous annealing line to achieve its process requirements, so the cost is high and the performance stability is poor.

The disadvantages are (1) the Al content in the steel is high, within the range of 1-8%, continuous casting is difficult; (2) the annealing time of the steel plate is between 2-20 minutes, the annealing time is short, it is difficult to make Mn rich purpose of set

[0009] Patent CN 102321854A provides a low-carbon high-manganese TRIP steel and its production method. Its advantage is that the tensile strength reaches 1000~1500MPa. The disadvantage is that a large amount of alloy is added to the steel, resulting in high cost

At the same time, the hot-rolling coiling temperature is 580 degrees, and the coiling temperature is low, which makes cold rolling difficult

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

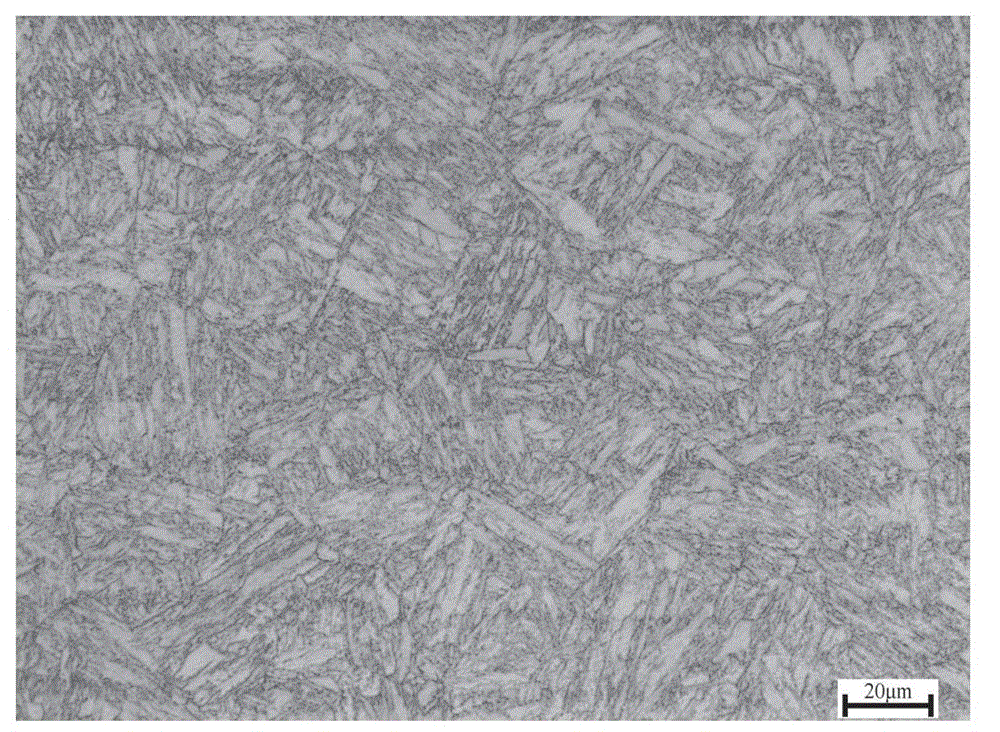

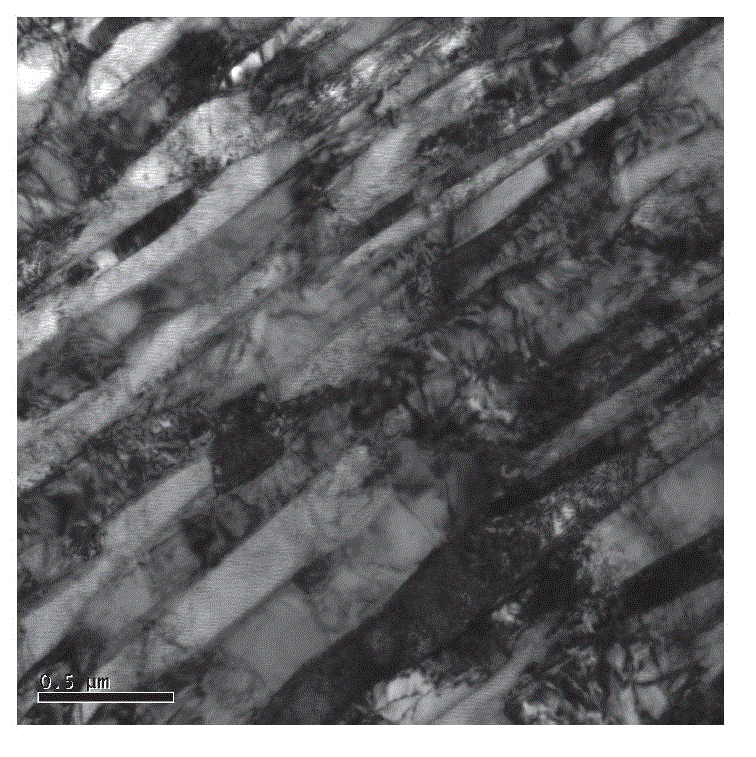

[0052] The metallographic structure of embodiment 3 is as figure 1 As shown, it can be clearly seen that the steel plate contains martensite and austenite structures. The transmission electron microscope photograph of embodiment 3 is as figure 2 As shown, a clear martensite lath morphology and austenite structure can be seen.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

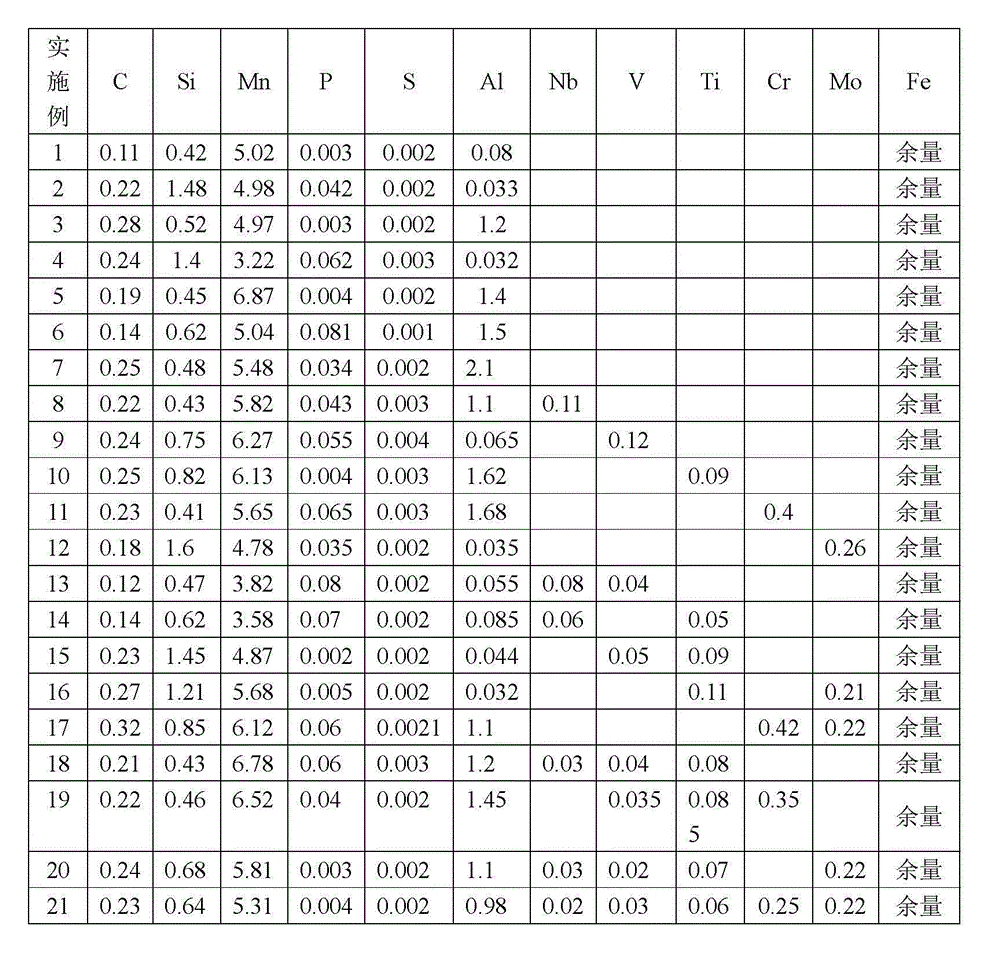

The invention discloses a high-strength plastic accumulation TRIP (Transformation-Induced Plasticity) steel plate and a preparation method thereof, wherein the high-strength plastic accumulation TRIP steel plate consists of the following elements: 0.08%-0.5% of C, 0.4%-2.0% of Si, 3%-8% of Mn, smaller than or equal to 0.10% of P, smaller than or equal to 0.02% of S, 0.02%-4% of Al, smaller than or equal to 0.01% of N, 0-0.5% of Nb, 0-0.5% of V, 0-0.5% of Ti, 0-2% of Cr, 0-1% of Mo, and the balance of Fe and unavoidable impurities. In a microstructure, martensites account for 30%-90% by area occupation ratio, austenites account for 5%-30% by volume fraction, and the remaining is few ferrites and cementites. The hot rolling heating-up temperature is 1100-1250 DEG C, the holding time is more than or equal to 2 hours, the initial rolling temperature is higher than or equal to 1100 DEG C, the final rolling temperature is 850-950 DEG C, and the coiling temperature is lower than 720 DEG C; a hot rolled plate is 2-4mm in thickness; and the cover annealing is furnace heating for heat preservation at 550-750 DEG C for 1-20 hours and then furnace cooling.

Description

technical field [0001] The invention belongs to the field of steel manufacturing for automobiles, and relates to a high-strength plastic TRIP steel plate with a strong plastic product ≥ 30 GPa% and a preparation method thereof. Background technique [0002] With the continuous improvement of people's requirements for automobile environmental protection, safety and energy saving, the automobile industry has put forward higher requirements for automobile steel, which not only requires high strength of automobile steel, but also requires good elongation of automobile steel to meet Stamping requirements for auto parts. In order to meet the requirements of the rapid development of the automobile industry, major steel companies in the world have successively developed the first-generation advanced high-strength steel represented by DP and TRIP steel, the second-generation advanced high-strength steel represented by TWIP steel, and QP steel and high-strength steel. The third gener...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/06C22C38/12C22C38/14C22C38/38C21D8/02

Inventor 郭金宇刘仁东王科强徐荣杰孙建伦王旭林利徐鑫吕冬

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com