Economic high-strength cold-rolled TRIP steel with product of strength and elongation greater than 20 GPa*% and manufacturing method of TRIP steel

An economical and strong plastic product technology, applied in the field of cold-rolled automobile steel manufacturing, can solve the problems of insignificant lightweight effect, high Al content, high Mn content, and achieve good cold forming performance and collision absorption capacity, steel grade The effect of excellent performance and simple preparation method

Active Publication Date: 2016-11-30

MAGANG (GROUP) HOLDING CO LTD +1

View PDF11 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The patent document with the application number CN 103088255 introduces a production process of high-strength plastic product low-alloy high-strength steel cold-rolled sheet for automobiles. Its advantage is that it can produce high-strength plastic product The low-alloy high-strength steel cold-rolled plate has a maximum strength-plasticity of 15GPa·%; the disadvantage is that due to its low-alloy high-strength composition design, its tensile strength is only 500MPa. Due to the limitation of strength, the lightweight effect after application is not obvious

[0005] The patent document with the application number CN 104264039 discloses a TRIP steel plate containing rare earth La and a tensile strength of not less than 780 MPa and a preparation method, but because it adds rare metals (rare earth La), the production cost is increased, and its strong The plastic products are all below 20GPa·% (the elongation is converted to A 80 : A 80 =A 50 ×1.15)

[0006] The patent document with the application number CN 103555902 discloses a heat treatment process for 980MPa-grade high-strength plasticity automotive steel, which is characterized in that the treated TRIP780 cold-rolled steel plate is quenched and then heated to a certain temperature for distribution to obtain a high-strength plasticity of 26.3 ~26.8GPa·%, 980MPa grade high-strength plastic product automotive steel with an elongation rate of 23.8~24.2%. The process has high requirements on the cooling rate and heating rate after annealing. The current annealing line cannot meet the process conditions, and it is difficult to realize large-scale industrial application.

[0007] The patent document with the application number CN 101353761 discloses a production method of high-strength Al-containing hot-dip galvanized TRIP steel. 22GPa; the disadvantage is that the Al content is too high, which leads to difficulties in continuous casting production, and it is difficult to achieve mass industrial production. At the same time, it will cause surface defects such as inclusions; manufacturing cost

[0008] The patent document with the application number CN 104694816 introduces a preparation method of high-Al medium-manganese steel with a strength-plasticity product greater than 30GPa·%. , the disadvantage is that the content of Mn and Al is too high, which leads to high production cost, difficulty in continuous casting and rolling, and difficulty in large-scale industrial application

[0009] The patent literature with the application number CN 102912219 introduces a high-strength plastic product medium Mn-TRIP steel, which is characterized in that the Mn content is between 3 and 8%. The advantage is that this steel has good strength and elongation, and the strong plastic product Reaching above 30GPa·%, the disadvantages are high Mn content, high production cost, difficulty in continuous casting and cold rolling, and difficult to achieve stable batch application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment example

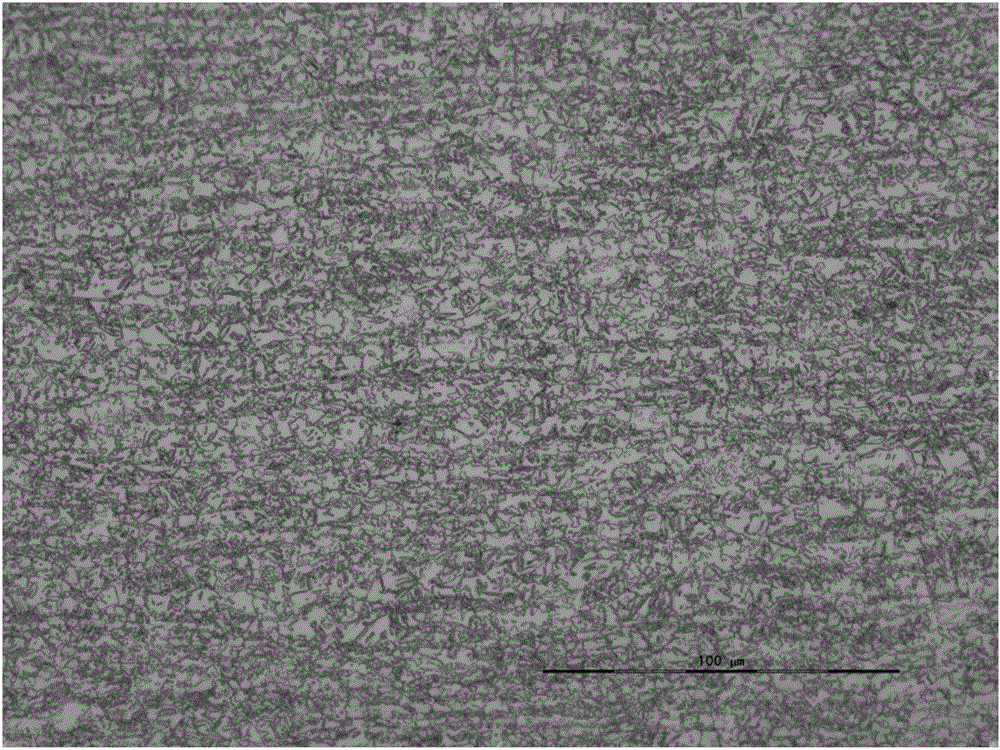

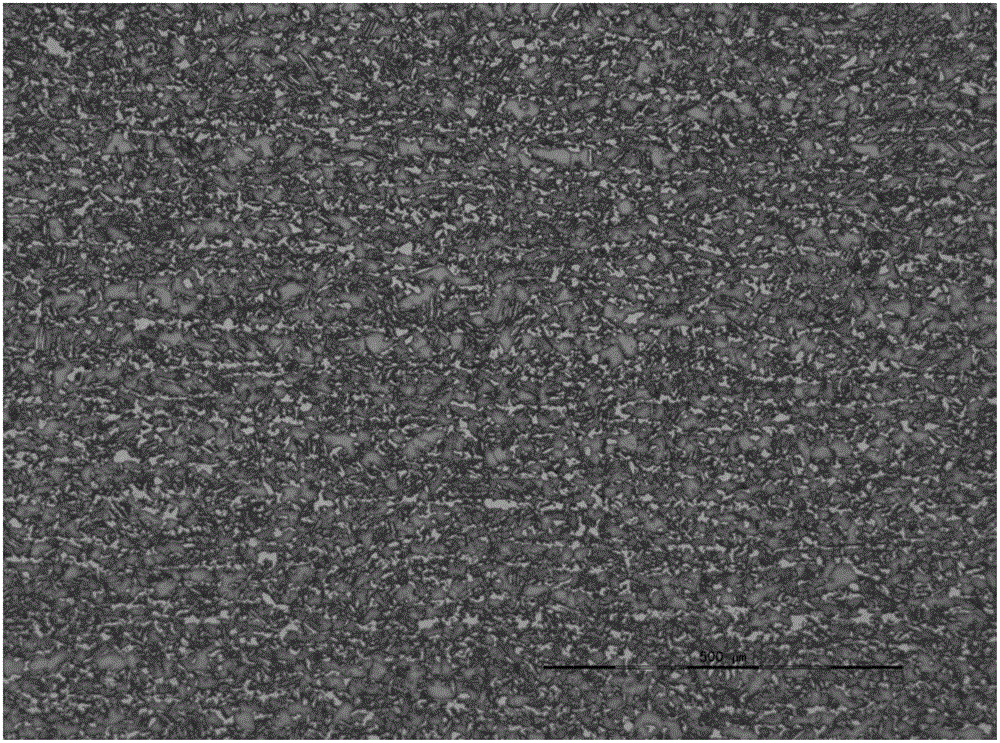

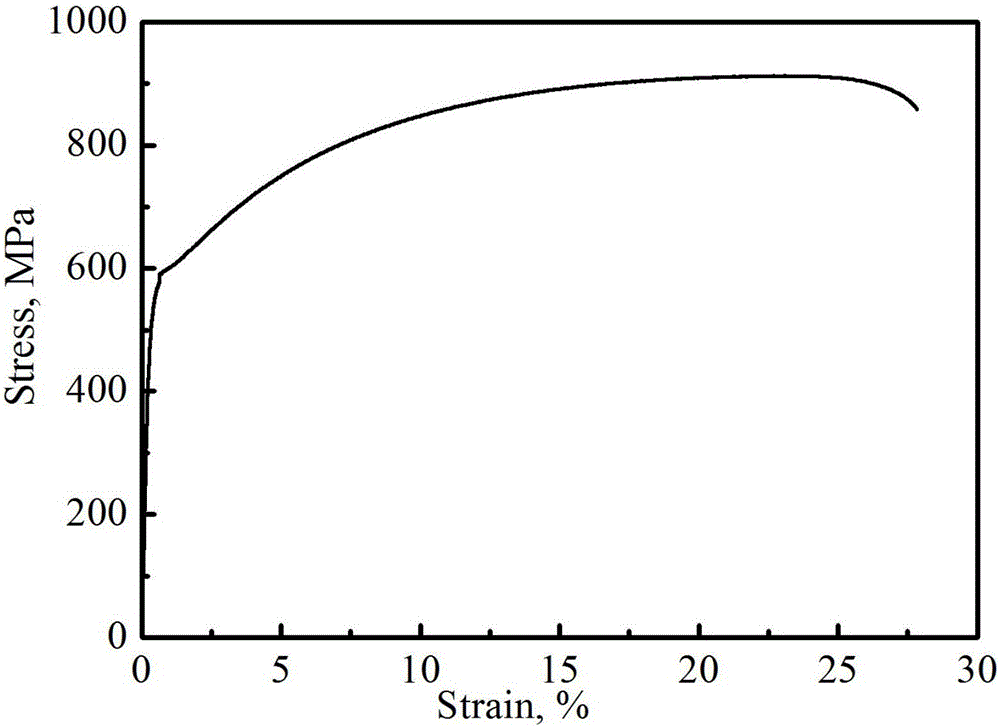

[0067]

[0068]

[0069] The steel produced by the invention is a high-strength TRIP steel with a tensile strength above 800MPa and an elongation above 24%, and its strength-plastic product is above 20GPa·%, the highest reaching 26.3GPa·%. While having high strength, the steel plate also has good cold forming performance and impact absorption capacity.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a production method of economic high-strength cold-rolled TRIP steel with the tensile strength no less than 800 MPa and the product of strength and elongation greater than 20 GPa*%. The steel is made from main chemical components, by weight percentage, 0.15-0.25% of C, 1.3-1.7% of Si, 1.5-2.5% of Mn, no more than 0.030% of P, no more than 0.020% of S, and 0.02-0.06% of Al, with the balance being Fe and inevitable impurities. The manufacturing method comprises the following steps: (1) melting and solidification; (2) hot continuous rolling of a casting blank or ingot casting; (3) pickling and cold rolling; and (4) continuous annealing. The product of strength and elongation of the TRIP steel is greater than 20 GPa*%, and can reach as high as 26.3 GPa*%. At the same time, the sheet shape, the surface quality, the stamping property and the welding property of the TRIP steel are ensured.

Description

technical field [0001] The invention relates to the field of cold-rolled automobile steel manufacturing, in particular to a production method of economical high-strength cold-rolled TRIP steel with a tensile strength of more than 800 MPa and a strength-plastic product greater than 20 GPa·%. Background technique [0002] Higher requirements for weight reduction, emission reduction, and high safety of automobiles have prompted the steel used in automobiles to gradually become lightweight and highly strengthened. As the strength increases, the toughness of the material will inevitably decrease. Therefore, when developing high-strength steel, the formability of the material must also be taken into account. At present, the strength-plastic product of traditional high-strength steel is generally below 15GPa·%, and TRIP steel, which has an excellent combination of high strength and high plasticity among the first generation of advanced high-strength steels, generally does not excee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/02C22C38/04C22C38/06C21D8/02

CPCC21D8/0226C21D8/0236C21D8/0273C22C38/02C22C38/04C22C38/06

Inventor 詹华刘永刚肖洋洋张武计遥遥高光泽霍俊熊华报

Owner MAGANG (GROUP) HOLDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com