Cold-rolled medium manganese steel with high strength and high plasticity and preparation method thereof

A high-plasticity, high-strength technology, applied in the field of high-strength and high-plasticity cold-rolled steel, can solve the problems of unsuitability for cold-rolled TRIP steel, unfavorable industrial production, inconvenient operation, etc. The effect of rolling cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

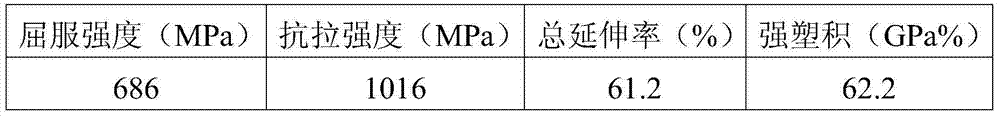

Examples

Embodiment

[0017] The medium manganese steel is smelted into a steel ingot, the composition of which is C=0.18%, Mn=10.62%, A1=4.06%, Nb=0.025% by weight percentage, and the balance is Fe and impurities. The steel ingot is heated to 1200°C, Keep warm for 2 hours, and forge into a steel billet with a cross-sectional area of 100mm×30mm.

[0018] Put the billet into a high-temperature furnace and heat it from room temperature to 1250°C, hold it for 2 hours, and then hot-roll it into a thin plate with a thickness of 4mm after 6-8 passes. The initial rolling temperature is 1150°C, and the final rolling temperature is not lower than 850°C. room temperature.

[0019] Heat treatment after rolling: keep the hot-rolled sheet in a heating furnace at 775°C for 1 hour, and quickly water-cool it to room temperature; temper the quenched steel sheet at 200°C for 20 minutes, then air-cool it to room temperature.

[0020] Pickling: Use 1:3 hydrochloric acid and water to pickle the heat-treated steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com