Method for discriminating bainite in hot rolled TRIP steel and calculating three phase ratio of hot rolled TRIP steel

A bainite and three-phase technology is applied in the field of identifying bainite in hot-rolled TRIP steel and calculating its three-phase comparison.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Take a small sample of 3.5mm×7mm×8mm on the test steel by wire cutting, roughly grind the six sides of the sample with coarse sandpaper, and finely grind the surface of the sample to be observed with fine sandpaper.

[0028] 2) Perform electrolytic polishing on the sample, the electrolyte is perchloric acid alcohol solution with glycerol (20% perchloric acid + 10% glycerin + 70% ethanol), voltage 15V, current 1.2A, polishing for 25s to remove surface stress.

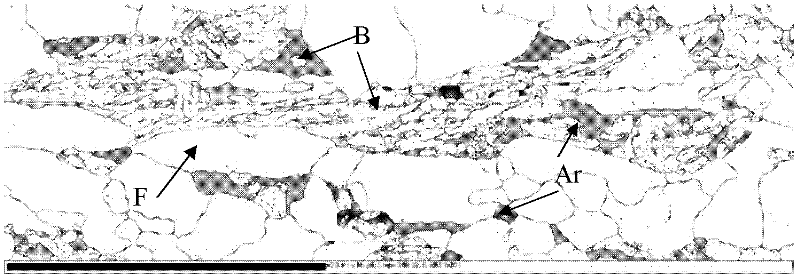

[0029] 3) Use the HKL Channel 5 EBSD system equipped with the ZEISS SUPRA55 field emission scanning electron microscope to perform orientation imaging analysis on the micro-area, and select the BCC phase and the FCC phase in the phase selection;

[0030] 4) Select a step size of 0.08 μm;

[0031] 5) After the EBSD data collection is completed, open the analysis software, and analyze and process the collected EBSD data as follows:

[0032] For BCC addition of >1o small-angle grain boundaries and >15o high-angle...

Embodiment 2

[0037] 1) Take a small sample of 3.5mm×7mm×8mm on the test steel by wire cutting, roughly grind the six sides of the sample with coarse sandpaper, and finely grind the surface of the sample to be observed with fine sandpaper.

[0038] 2) Perform electrolytic polishing on the sample. The electrolyte is perchloric acid alcohol solution with glycerol (20% perchloric acid + 10% glycerin + 70% ethanol), voltage 15V, current 1.2A, polishing for 23s to remove surface stress.

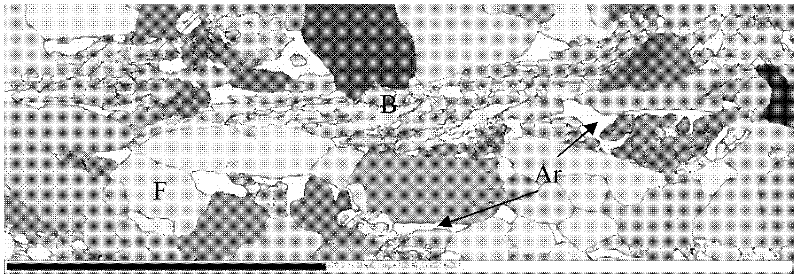

[0039] 3) Use the HKL Channel 5 EBSD system equipped with the ZEISS SUPRA55 field emission scanning electron microscope to perform orientation imaging analysis on the micro-area, and select the BCC phase and the FCC phase in the phase selection;

[0040] 4) Select a step size of 0.15 μm;

[0041] 5) After the EBSD data collection is completed, open the analysis software, and analyze and process the collected EBSD data as follows:

[0042]Add two types of grain boundaries, the small-angle grain boundary of >1o ...

Embodiment 3

[0046] 1) Take a small sample of 3.5mm×7mm×8mm on the test steel by wire cutting, roughly grind the six sides of the sample with coarse sandpaper, and finely grind the surface of the sample to be observed with fine sandpaper.

[0047] 2) Perform electrolytic polishing on the sample. The electrolyte is perchloric acid alcohol solution with glycerin (20% perchloric acid + 10% glycerin + 70% ethanol), voltage 15V, current 1.2A, polishing for 20s to remove surface stress.

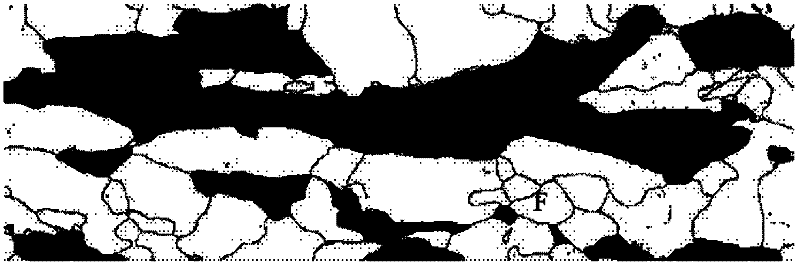

[0048] 3) Use the HKL Channel 5 EBSD system equipped with the ZEISS SUPRA55 field emission scanning electron microscope to perform orientation imaging analysis on the micro-area, and select the BCC phase and the FCC phase in the phase selection;

[0049] 4) Select a step size of 0.15 μm;

[0050] 5) After the EBSD data collection is completed, open the analysis software, and analyze and process the collected EBSD data as follows:

[0051] Add two types of grain boundaries, the small-angle grain boundary of >1o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com