Ultra-high strength Ausaged steels with excellent cryogenic temp. toughness

A technology of austenite and austenite grains, applied in the production field of this steel plate, can solve problems such as hydrogen-induced cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

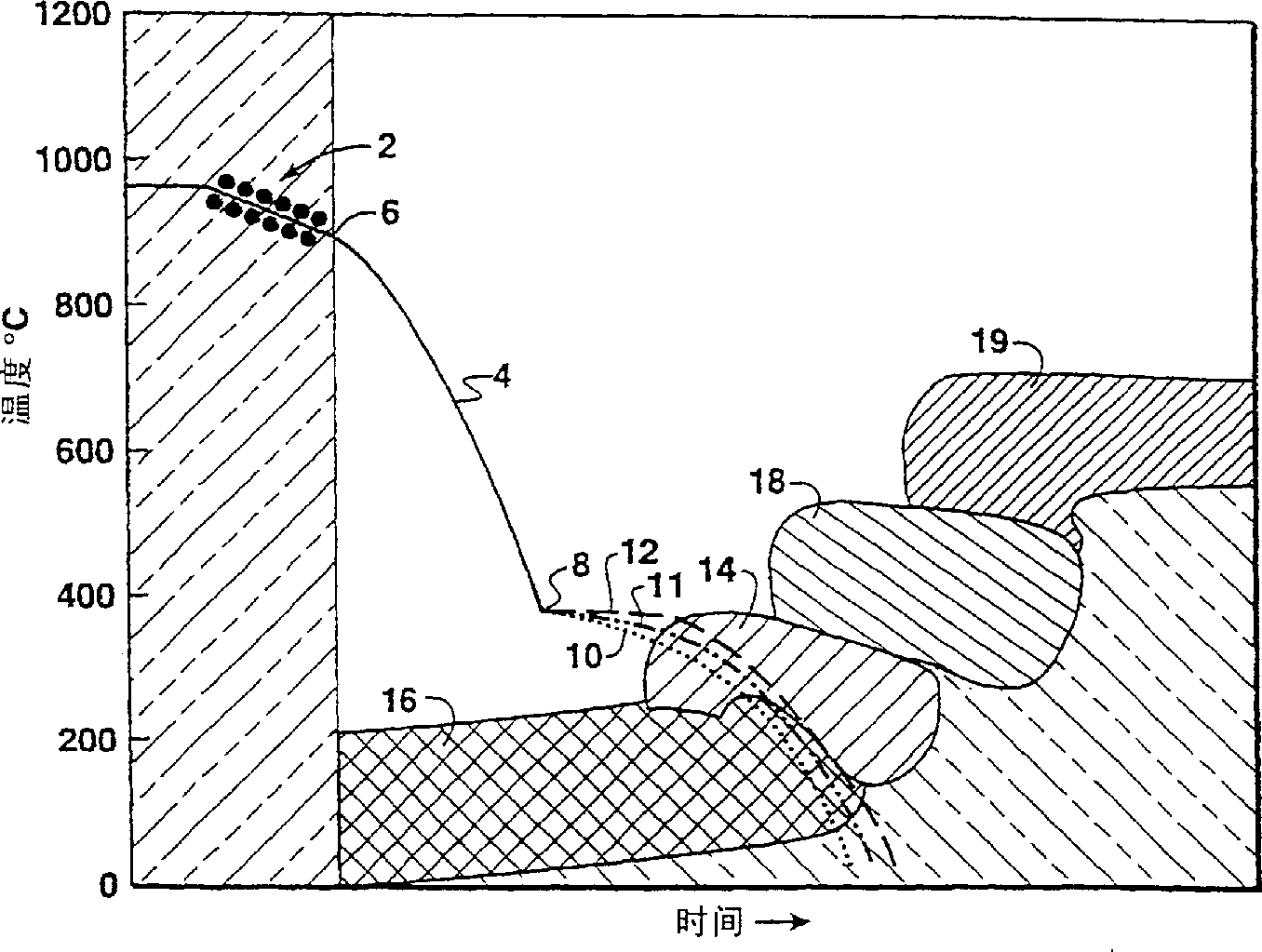

Method used

Image

Examples

Embodiment Construction

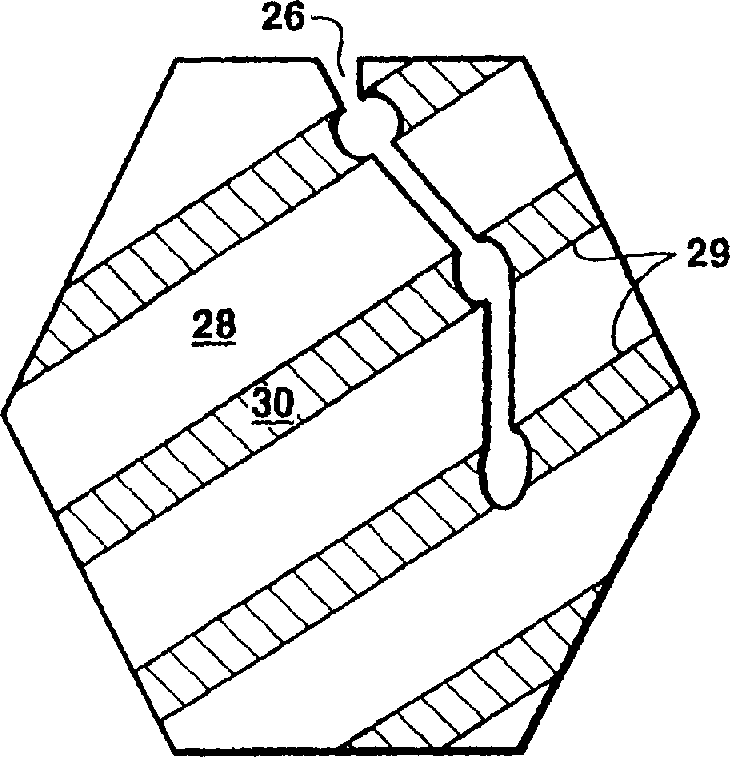

[0030] The present invention relates to the development of a new type of HSLA steel satisfying the above requirements. The basis of the present invention is to produce intrinsic toughening and microstructure toughening through a new combination of chemical composition and treatment method of steel, thereby reducing DBTT and improving toughness under the condition of high tensile strength. Intrinsic toughening is achieved by a proper balance of important alloying elements in the steel, which is described in detail in this specification. Toughening of the microstructure is achieved by obtaining a very small equivalent grain size and promoting the formation of a microlamellar structure. refer to Figure 2B, The microlamellar structure of the steel according to the invention is preferably composed of laths 28 dominated by fine-grained lower bainite or fine-grained martensite alternately with austenite thin film layers 30 . Preferably, the average thickness of the austenitic film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com