Quenching and annealing preparation method of ultrahigh-strength thin steel plate for automobiles

A kind of quenching annealing and ultra-high technology, which is used in manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problem of only reaching tensile strength, and achieve the effect of ensuring mechanical properties, promising prospects, and simple and feasible heat treatment process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The cast slab with the composition shown in Table 1 is hot-rolled and cold-rolled to obtain a cold-rolled thin steel sheet of required thickness.

[0027] Table 1 is the chemical composition (mass percentage) of embodiment

[0028] The chemical composition (wt.%) of the embodiment of table 1

[0029]

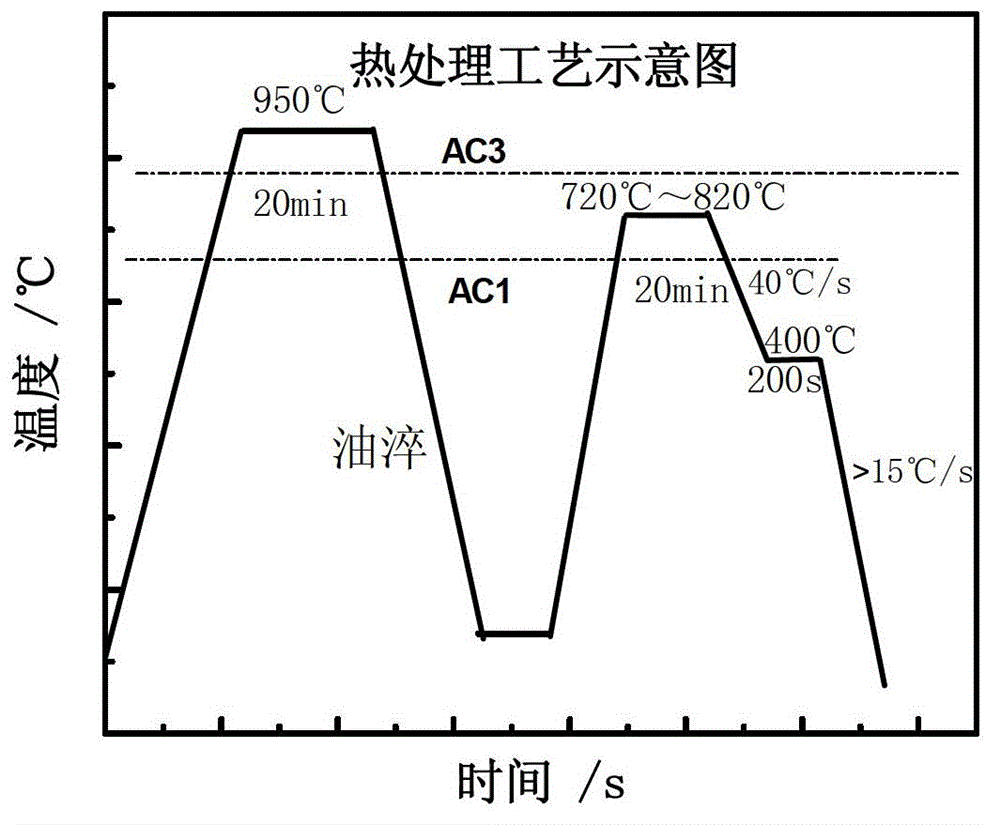

[0030] The quenching process is to heat the cold-rolled low-carbon steel plate with a thickness of 1.5mm to 2mm in a heating furnace to 950°C for 20 minutes, and then perform oil quenching.

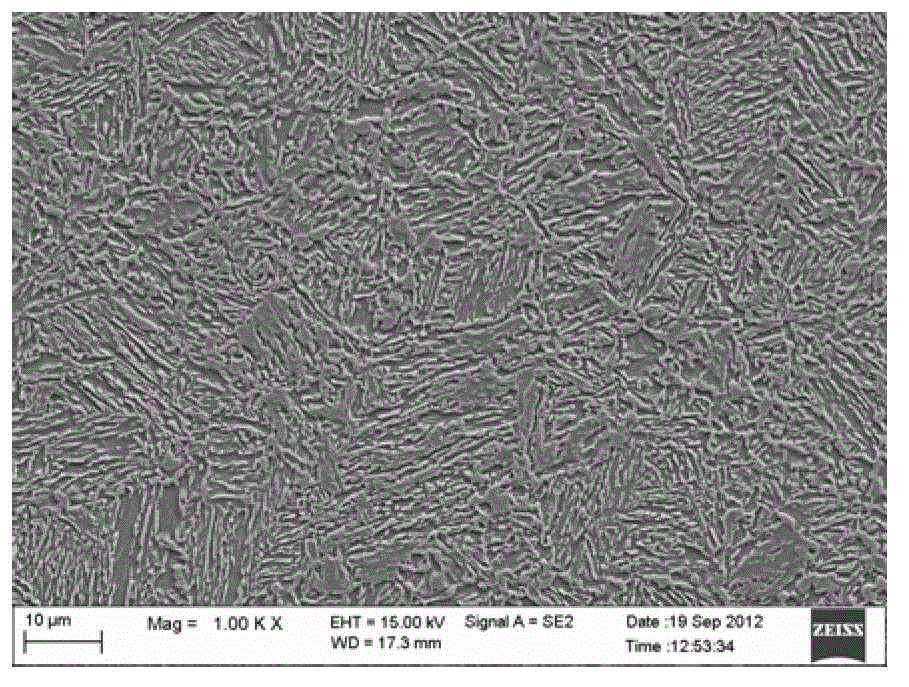

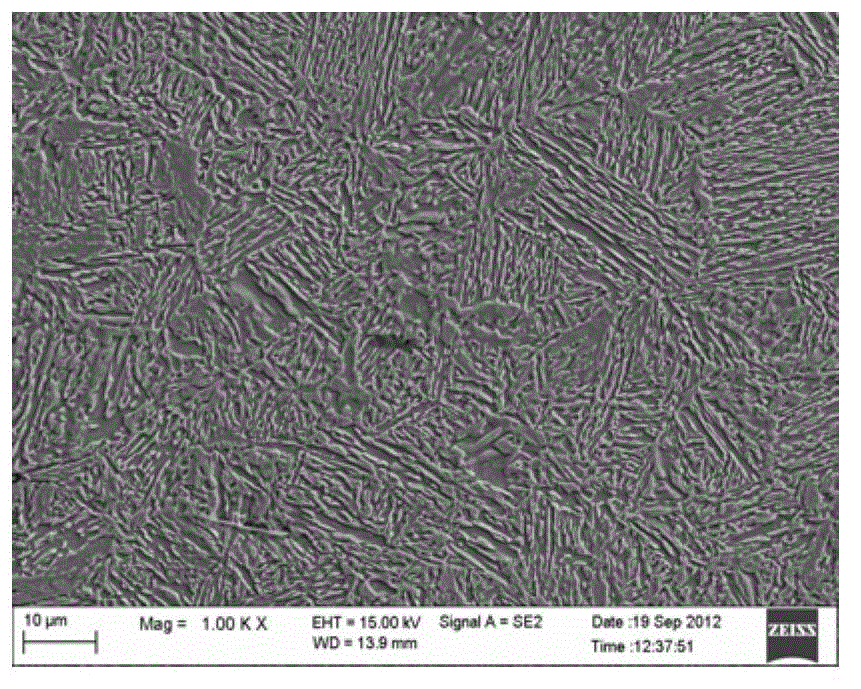

[0031] In the present invention, the continuous annealing temperature in the two-phase region is 760°C and 780°C, respectively heated to the temperature at 5°C / s and kept at this temperature for 1200s, then cooled at a cooling rate of 40°C / s to about 400°C and kept at 200s, and then heated at a temperature greater than 15°C. The cooling rate of ℃ / s is quickly cooled to room temperature. The properties corresponding to different chemical compositions and process parameters are sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com