Nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steels

a technology of nanocarbide precipitation and structural steel, which is applied in the field of nickel, chromium stainless martensitic steel alloy, can solve the problems of poor general corrosion resistance of ultrahigh-strength steels, and inability to meet the requirements of use, so as to achieve easy work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

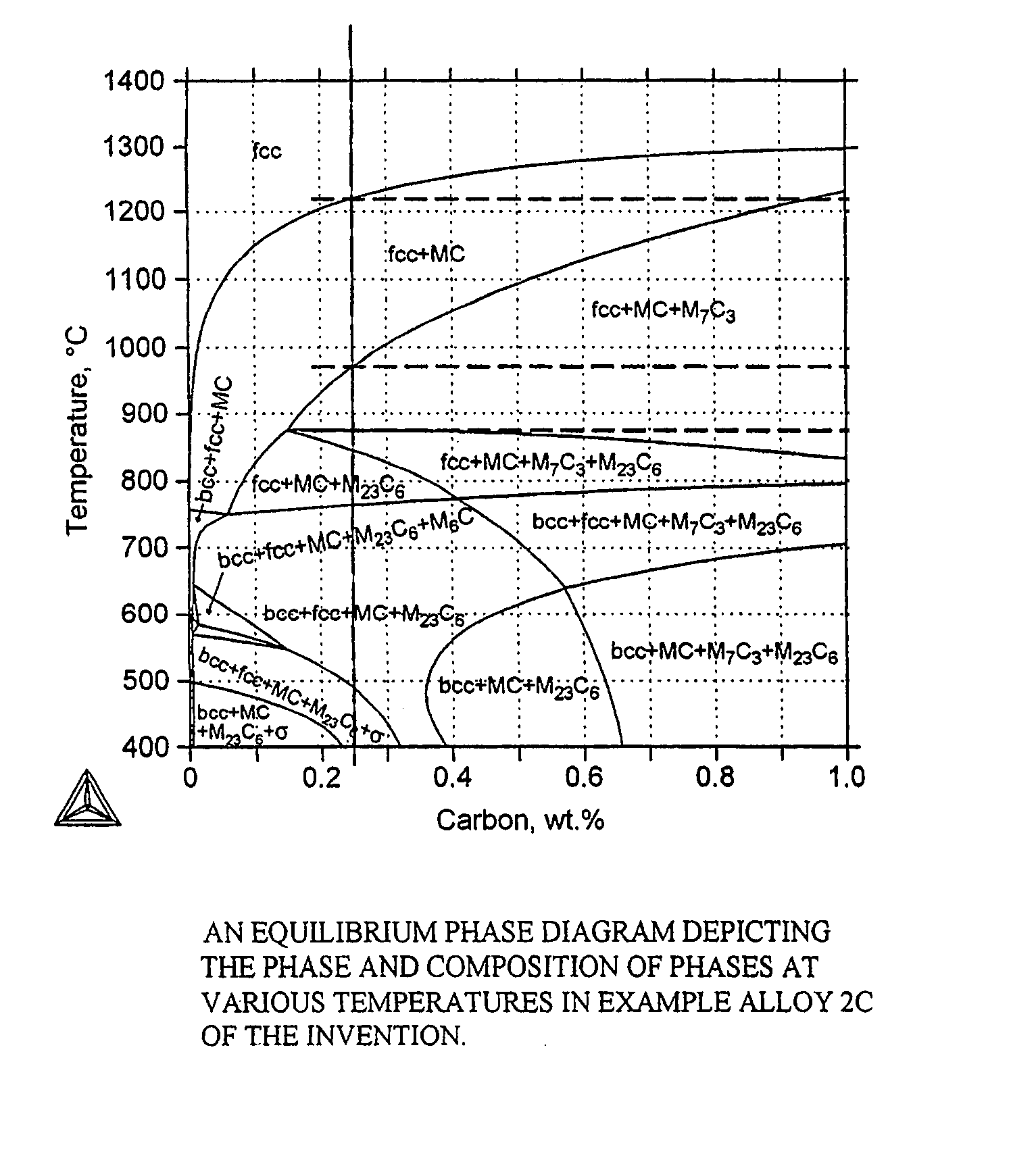

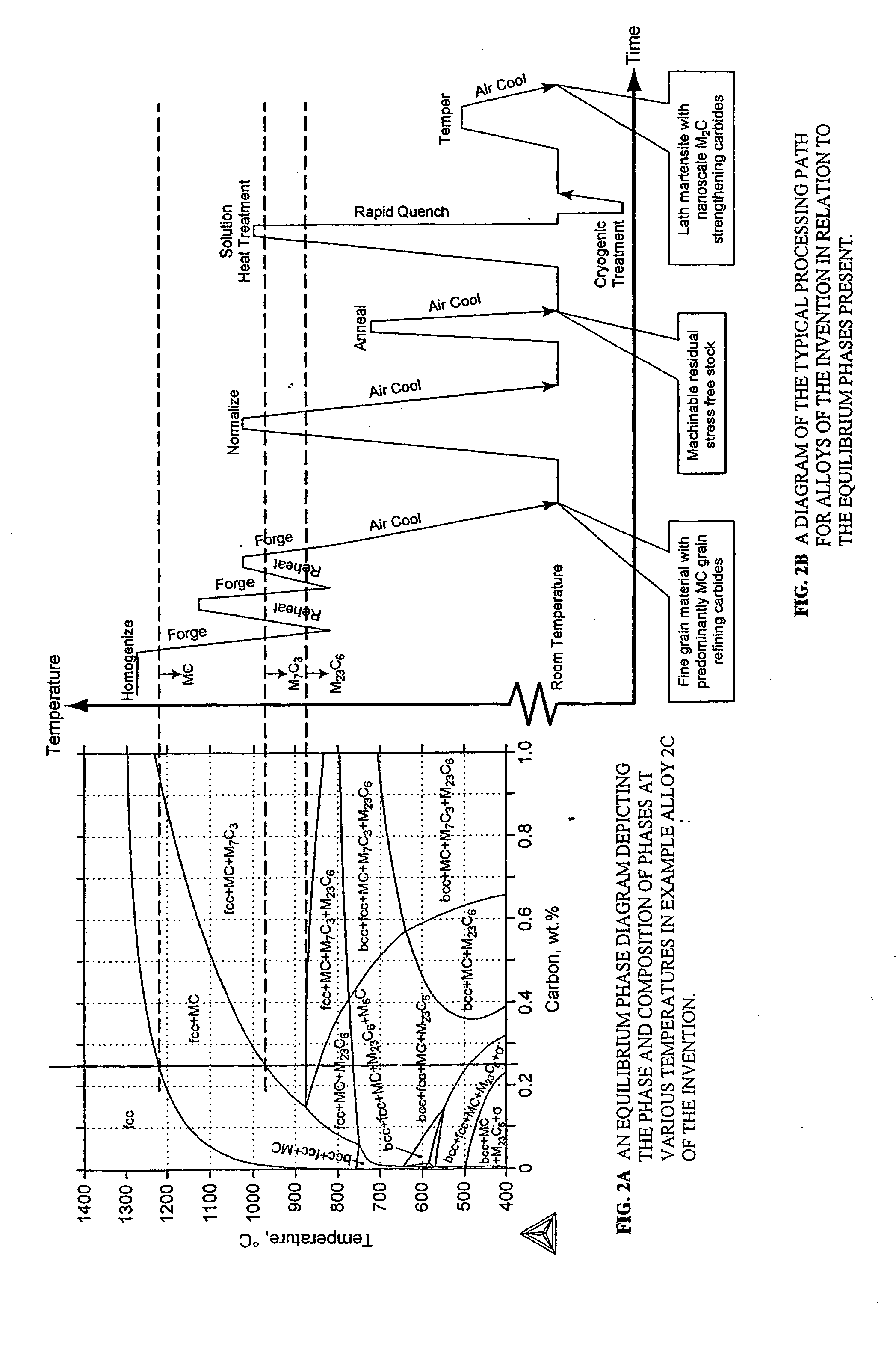

[0084] Alloy 1 in TABLE 1 was vacuum induction melted (VIM) to a six inch diameter electrode which was subsequently vacuum arc remelted (VAR) to a eight inch diameter ingot. The material was homogenized for seventy-two hours at 1200° C., forged and annealed according to the preferred processing techniques described above and depicted in FIGS. 2A and 2B. Dilatometer samples were machined and the Ms temperature was measured as 175° C. by quenching dilatometry and 1% transformation fraction.

[0085] Test samples were machined, solution heat treated at 1025° C. for one hour, oil quenched, immersed in liquid nitrogen for one hour, warmed to room temperature and tempered at 482° C. for eight hours. The measured properties are listed in TABLE 2 below.

TABLE 2Various measured properties for Alloy 1PropertyValueYield Strength205ksiUltimate Tensile Strength245ksiElongation10%Reduction of Area48%Hardness51HRC

example 2

[0086] Alloy 2A in TABLE 1 was vacuum induction melted (VIM) to a six inch diameter electrode which was subsequently vacuum arc remelted (VAR) to a eight inch diameter ingot. The ingot was homogenized for twelve hours at 1190° C., forged and rolled to 1.500 inch square bar starting at 1120° C., and annealed according to the preferred processing techniques described above and depicted in FIGS. 2A and 2B. Dilatometer samples were machined and the Ms temperature was measured as 265° C. by quenching dilatometry and 1% transformation fraction.

[0087] Test samples were machined from the square bar, solution heat treated at 1050° C. for one hour, oil quenched, immersed in liquid nitrogen for one hour, warmed to room temperature, tempered at 500° C. for five hours, air cooled, immersed in liquid nitrogen for one hour, warmed to room temperature and tempered at 500° C. for five and one-half hours. The measured properties are listed in TABLE 3 below. The reference to the corrosion rate of 15-...

example 3

[0089] Alloy 2B in TABLE 1 was vacuum induction melted (VIM) to a six inch diameter electrode which was subsequently vacuum arc remelted (VAR) to a eight inch diameter ingot. The ingot was homogenized for twelve hours at 1190° C., forged and rolled to 1.000 inch diameter round bar starting at 1120° C. and annealed according to the preferred processing techniques described above and depicted in FIGS. 2A and 2B. Dilatometer samples were machined and the Ms temperature was measured as 225° C. by quenching dilatometry and 1% transformation fraction.

[0090] Test samples were machined from the round bar, solution heat treated at 1100° C. for 70 minutes, oil quenched, immersed in liquid nitrogen for one hour, warmed to room temperature and tempered at 482° C. for twenty-four hours. The measured properties are listed in TABLE 5 below.

TABLE 5Various measured properties for Alloy 2BPropertyValueYield Strength211ksiUltimate Tensile Strength247ksiElongation17%Reduction of Area62%Hardness51HRC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com