Stope mine pressing three-dimensional physical simulation test stand

A technology for simulating test benches and three-dimensional physics, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as inability to observe model changes in depth, inability to simulate coal seam mining tests with large dip angles to the maximum extent, and inability to simulate deep coal seam mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

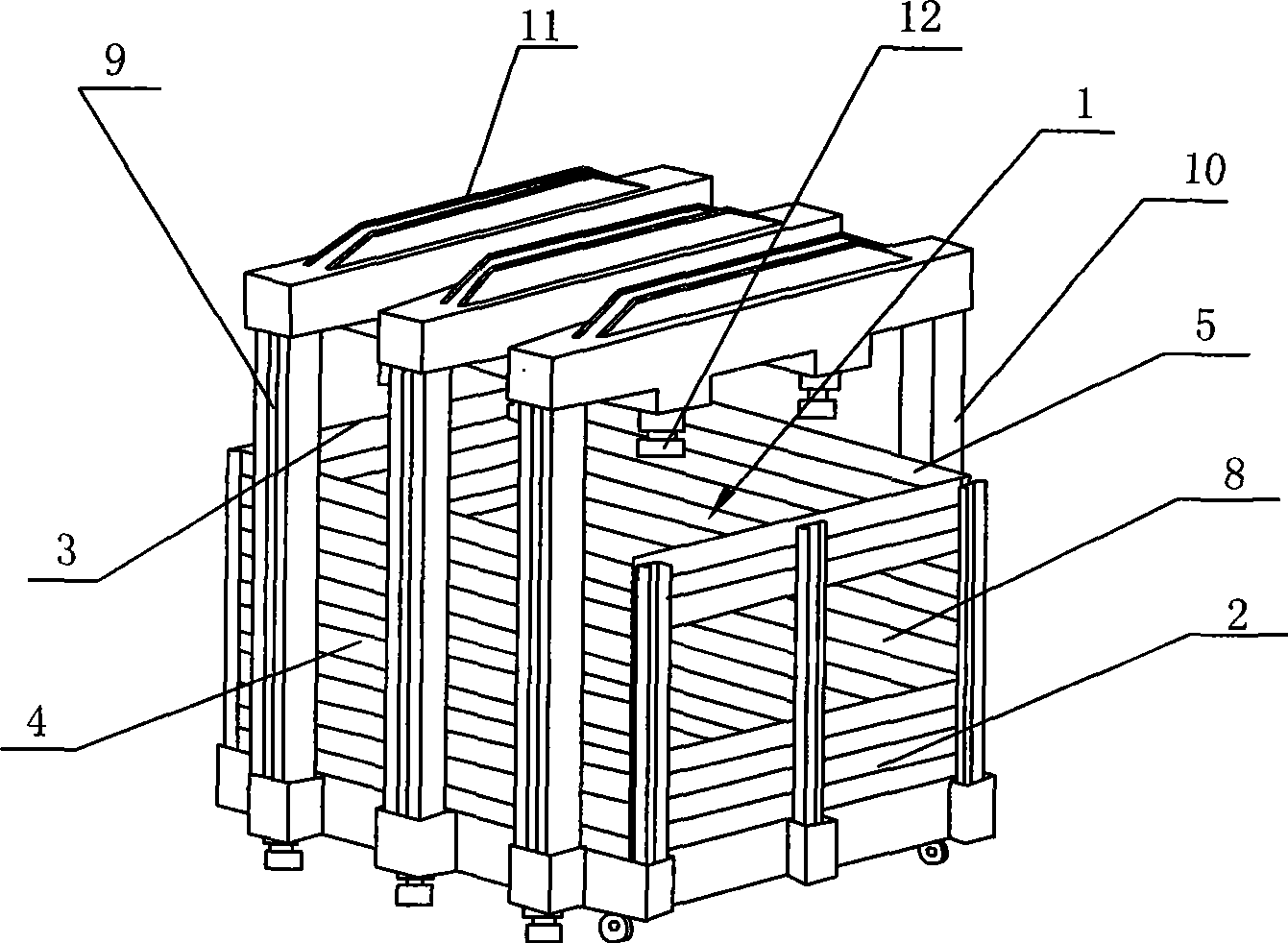

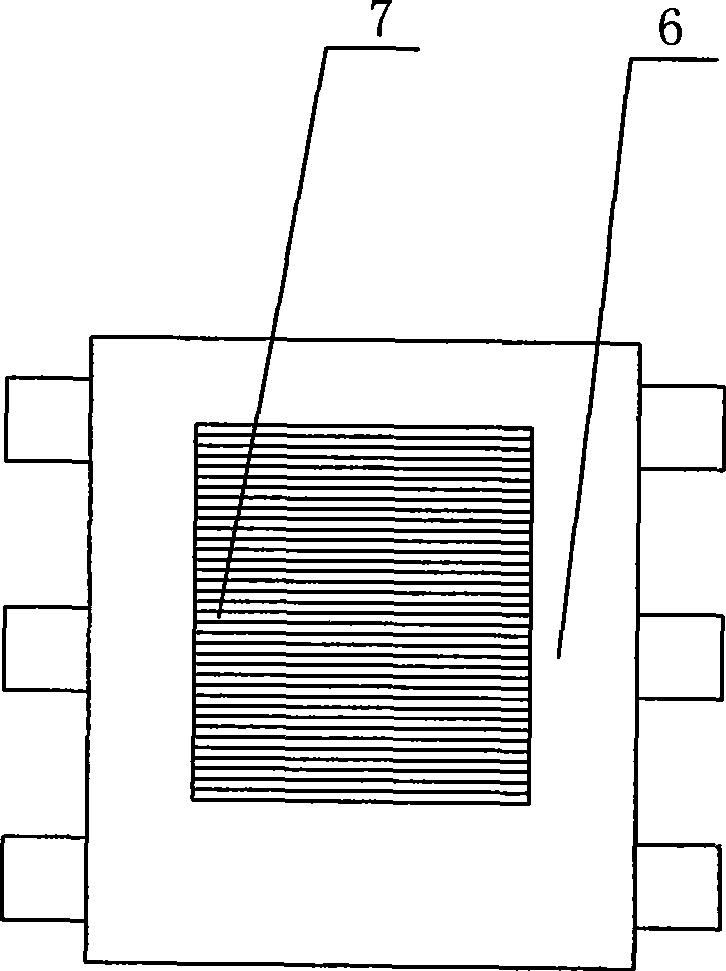

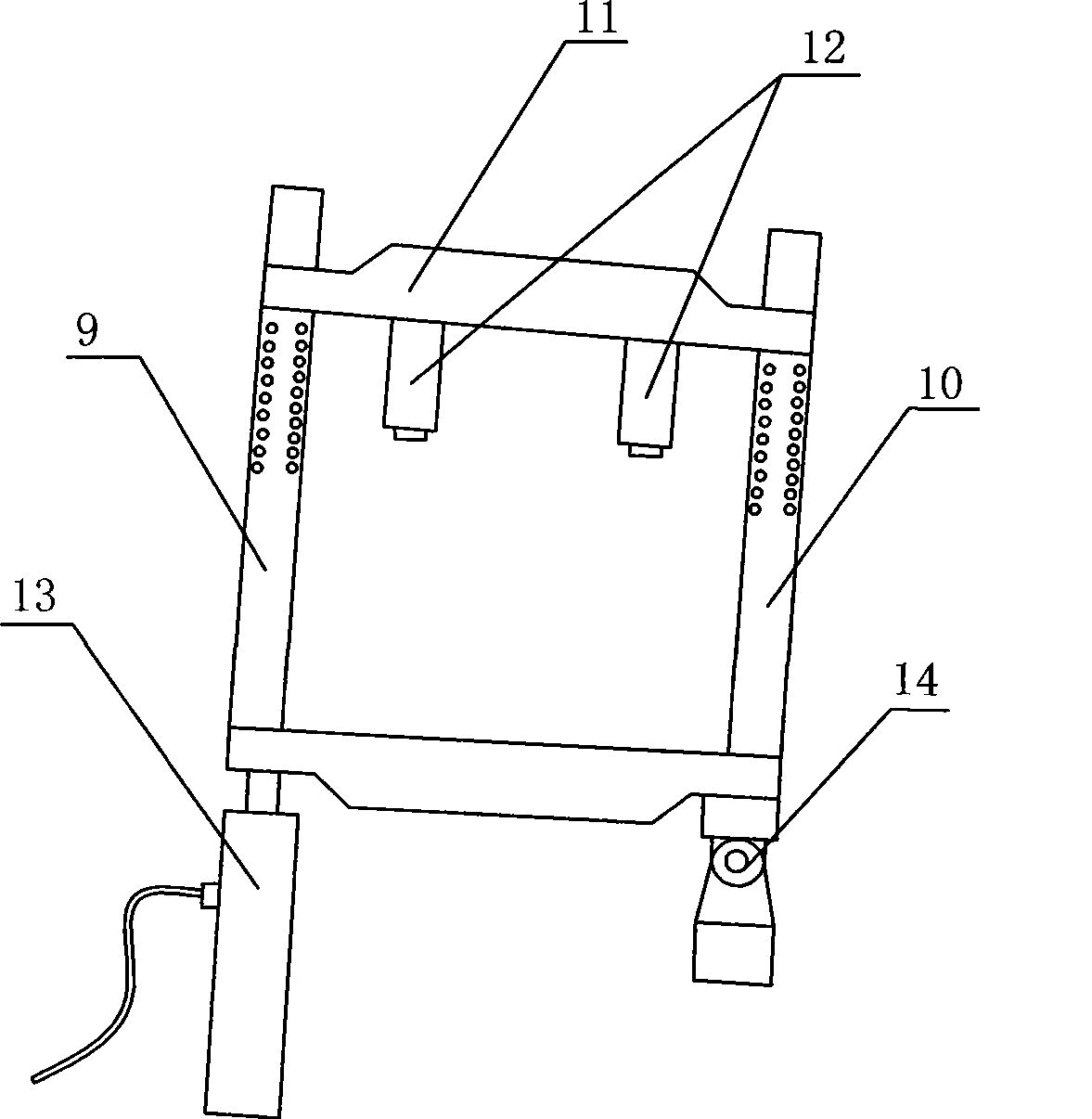

[0034] Embodiment 1, see figure 1 , figure 2 , image 3 and Figure 4 , a three-dimensional physical simulation test bed for mine pressure in a stope, including a frame-type model table for carrying a model, the frame-type model table includes an upper opening 1, and side wall panels 2, 3 located at the front, rear, left and right , 4, 5, and base plate 6. The above-mentioned side wall panels 2, 3, 4, and 5 are formed by splicing a plurality of slats sequentially from top to bottom, and the slats and the corresponding reinforcement parts are detachably connected. The corresponding slats can be disassembled on the corresponding side plates; the mining opening is set on the base plate 6, and a detachable sealing slat 7 is provided at the mining opening. When it is necessary to simulate the coal mining test of the bottom plate, the sealing slat 7 to proceed. A high-strength toughened glass area is set on the side wall panel 2 at the front to form an observation window 8 . ...

Embodiment approach 2

[0037] In Embodiment 2, the frame-type model table does not need to be designed into two parts, the front half model table A and the rear half model table B described in the above method. The other parts may take the same technical measures as the corresponding parts in Embodiment 1.

[0038] The control system, testing system and hydraulic system related to the present invention should be able to be designed by skilled personnel under the guidance of the above spirit and in combination with the specific application of the present invention. For example, digital instruments can be used in the control system to measure and control the pressure; the DH3815 static strain measurement system produced by Jiangsu Donghua Testing Technology Co., Ltd. can be used in the test system, which can perform multi-point high-speed roving detection of physical quantities such as pressure and displacement. The resolution of the voltage signal whose output voltage is less than 20mv can reach 1 / 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com