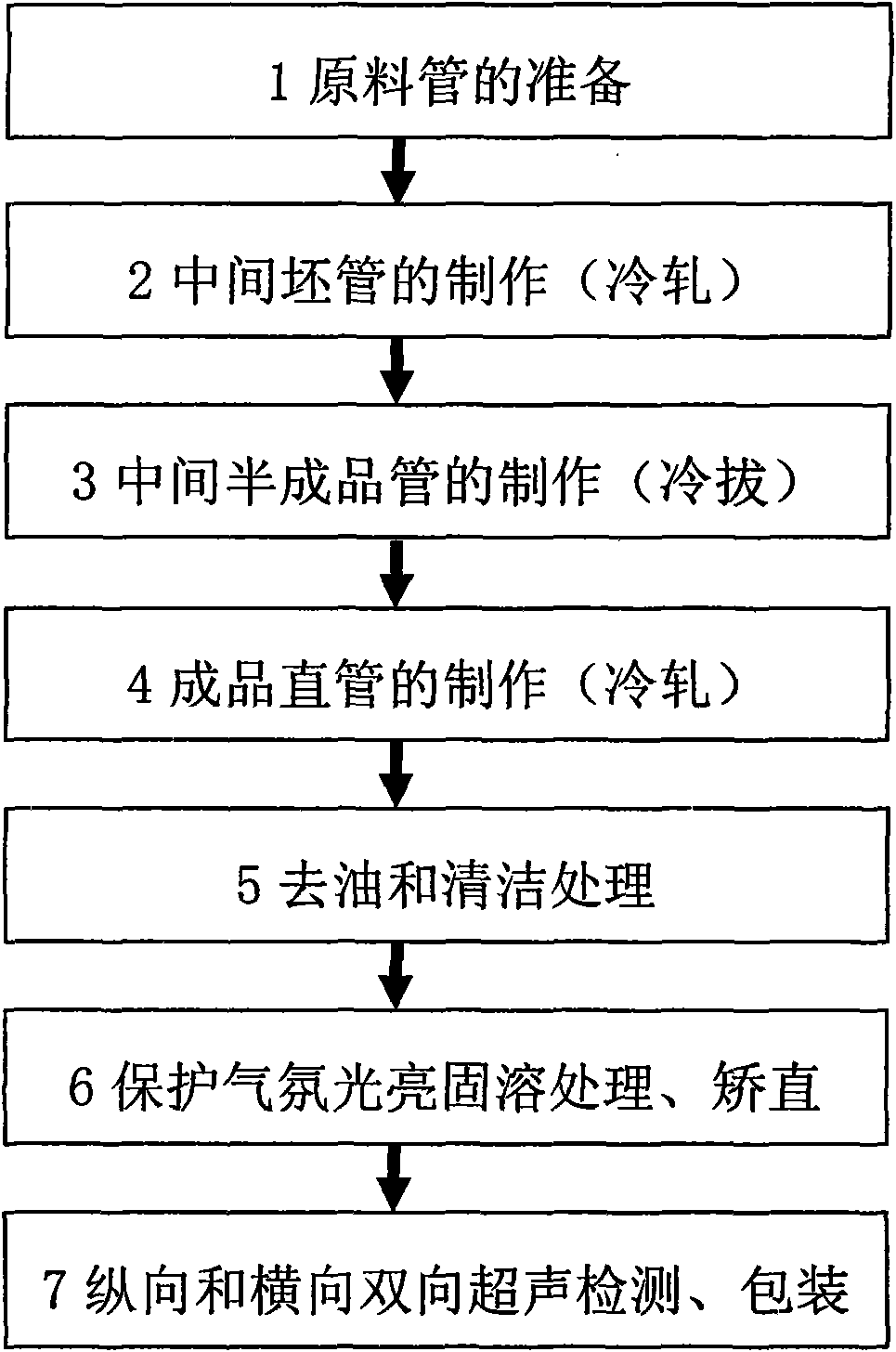

Method for manufacturing stainless steel heat transfer pipe of nuclear heat exchanger

A technology of heat exchangers and manufacturing methods, which is applied in the direction of manufacturing tools, heat treatment furnaces, metal rolling, etc., can solve the problems of restricting the development speed of nuclear power industry, immature manufacturing methods, and long construction period, so as to improve the process and mechanical properties , Thin pipe wall, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the stainless steel heat transfer straight tube of nuclear power heat exchanger with a small diameter and a thin wall whose outer diameter is 19.05 ± 0.15mm, wall thickness is 1.375 ± 0.10mm, adjustable in length, is manufactured according to the following steps:

[0040] (1) After the Φ67×4.8mm tube blank obtained after perforation is trimmed, smoothed, pickled and ground, the raw material tube is obtained;

[0041] (2) Cold rolling the raw material tube into an intermediate blank tube with an outer diameter of 38±0.50mm and a wall thickness of 2.4±0.24mm through cold rolling equipment and a ring-type die;

[0042] (3) Carry out degreasing and solid solution treatment (1100±20° C.) to the intermediate blank tube in step (2), and carry out straightening and pickling treatment after heat treatment;

[0043] (4) Cold-drawing the intermediate blank tube after pickling in step (3) by cold-drawing equipment in conjunction with the inner mold head to reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com