Method for accurately controlling band-steel ductility when welding joints pass leveling machine

A technology of elongation and flattening machine, applied in the direction of elongation control, etc., can solve the problems of elongation not meeting process requirements and waste, and achieve the effect of simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

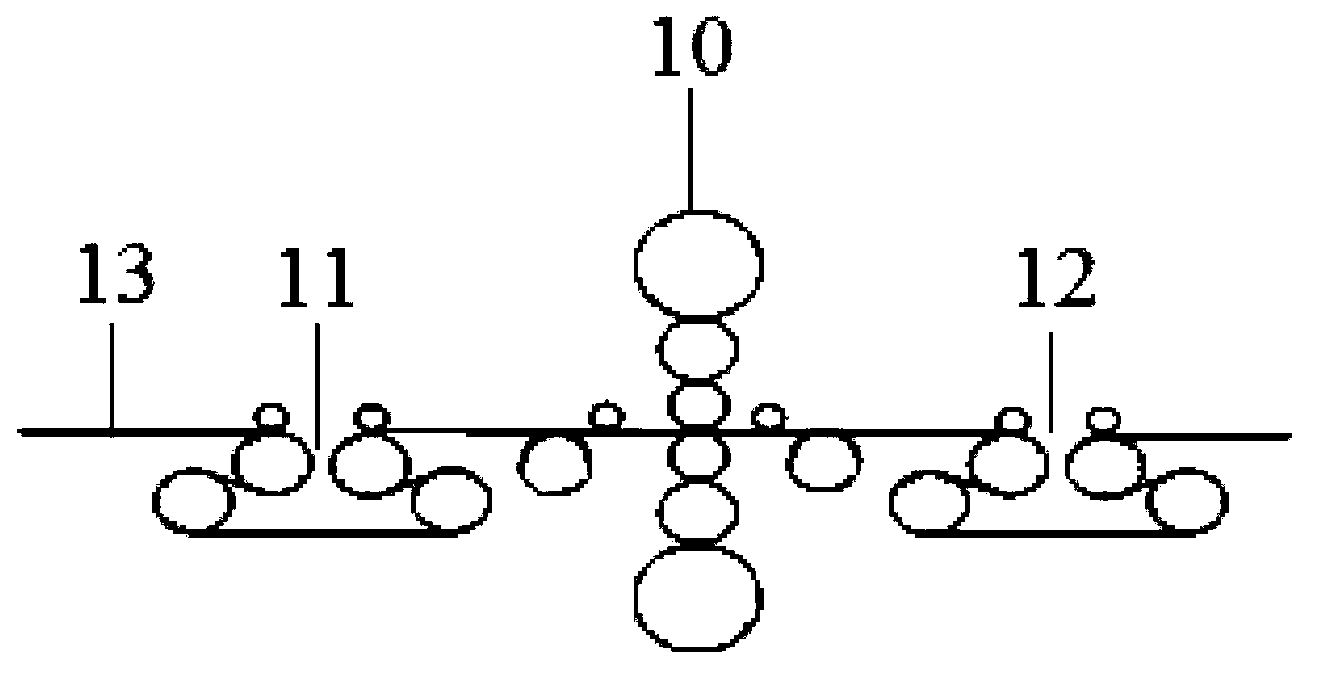

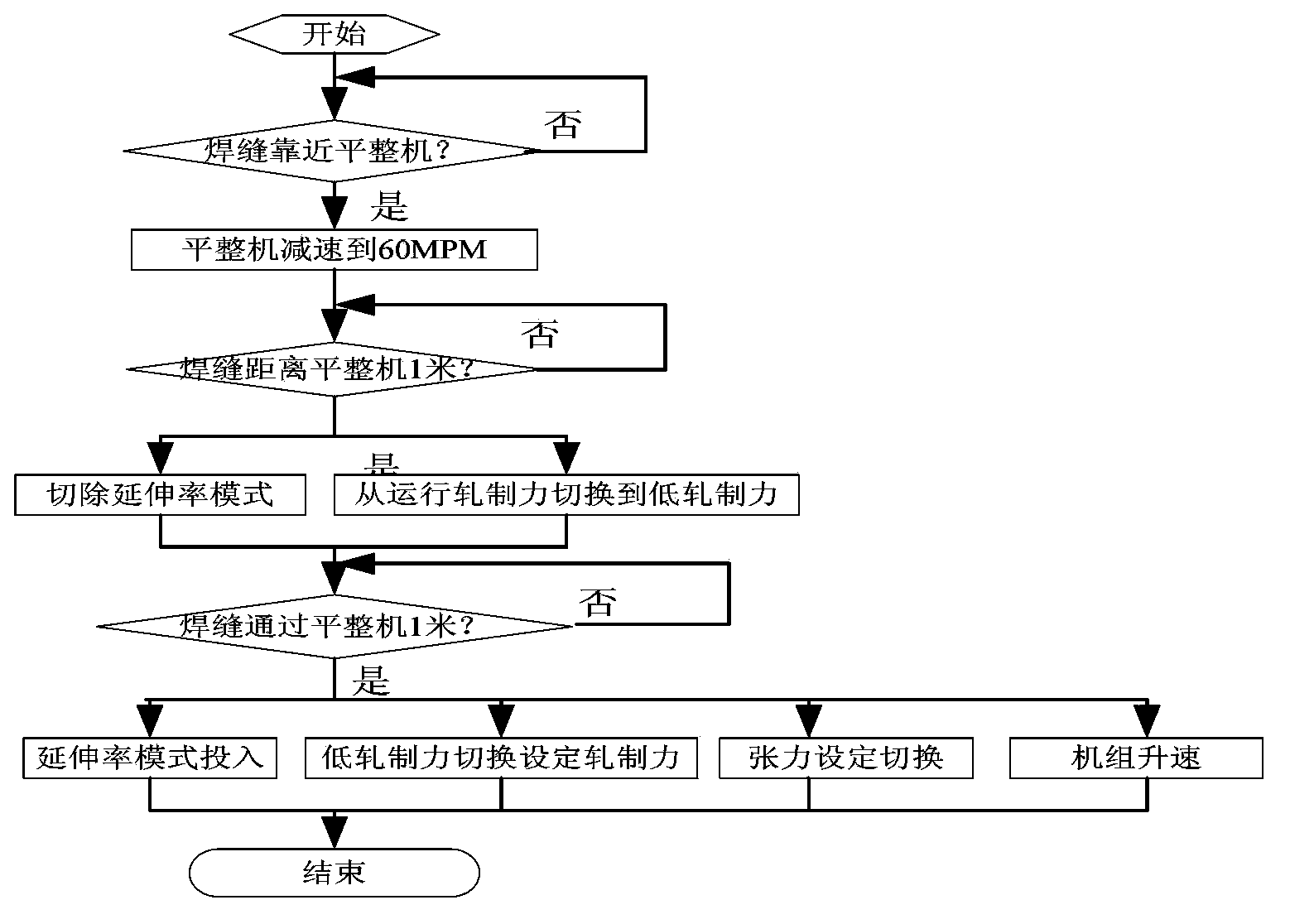

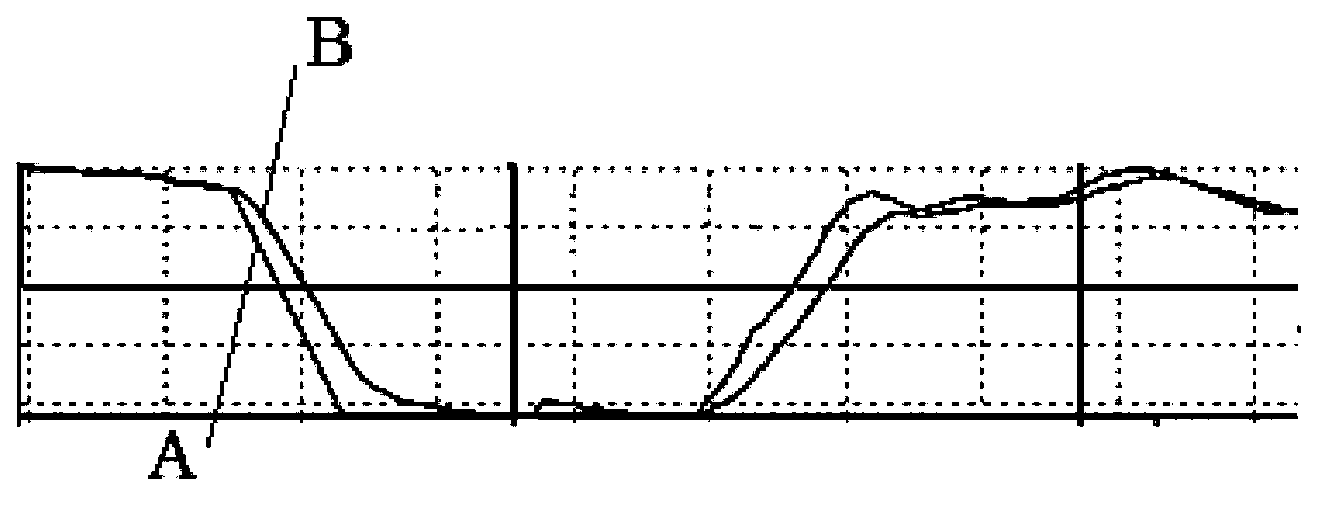

[0029] The method for accurately controlling the elongation of the strip when the weld seam passes through the tempering machine according to the present invention will be further described below according to the specific embodiments and the accompanying drawings, but the specific embodiments and related descriptions do not constitute technical solutions for the present invention undue limitation.

[0030] Such as Figure 5 As shown, follow the steps below to control the elongation of the strip when the weld passes through the skin pass machine:

[0031] (1) start;

[0032] (2) When the strip steel travels to the welding seam close to the temper machine, reduce the strip steel traveling speed to 60m / min, and after the deceleration is completed, the distance between the weld seam and the temper machine is 2m;

[0033] (3) When the distance between the weld seam and the tempering machine is less than 1m, quickly reduce the rolling force to 80-150 tons at a speed of 400 tons / s;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com