Parameter control method for initial segment of continuous annealing six-roll cold rolling temper mill

A technology of parameter control and tempering machine, applied in rolling force/gap control, metal rolling, elongation control, etc., can solve the problems of reducing machine composition rate, increasing time, increasing head cutting length, etc., to achieve The implementation is simple and easy to operate, the effect of improving the utilization rate of finished products and reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0029] The embodiment of the present application provides a method for controlling the parameters of a six-roll cold-rolled skin pass mill with continuous annealing of weld seams. The control method includes the following steps:

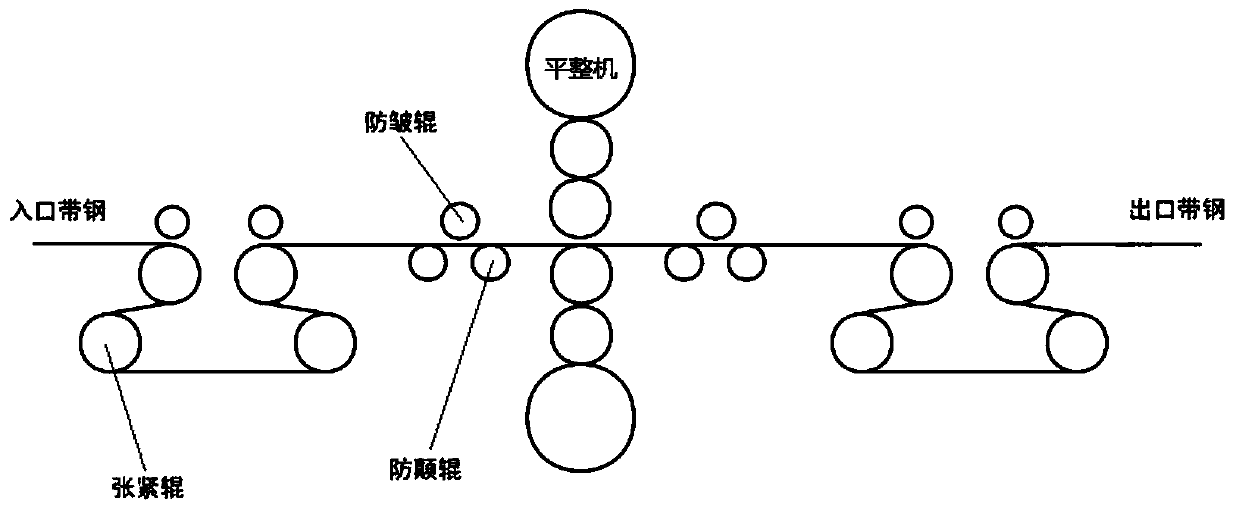

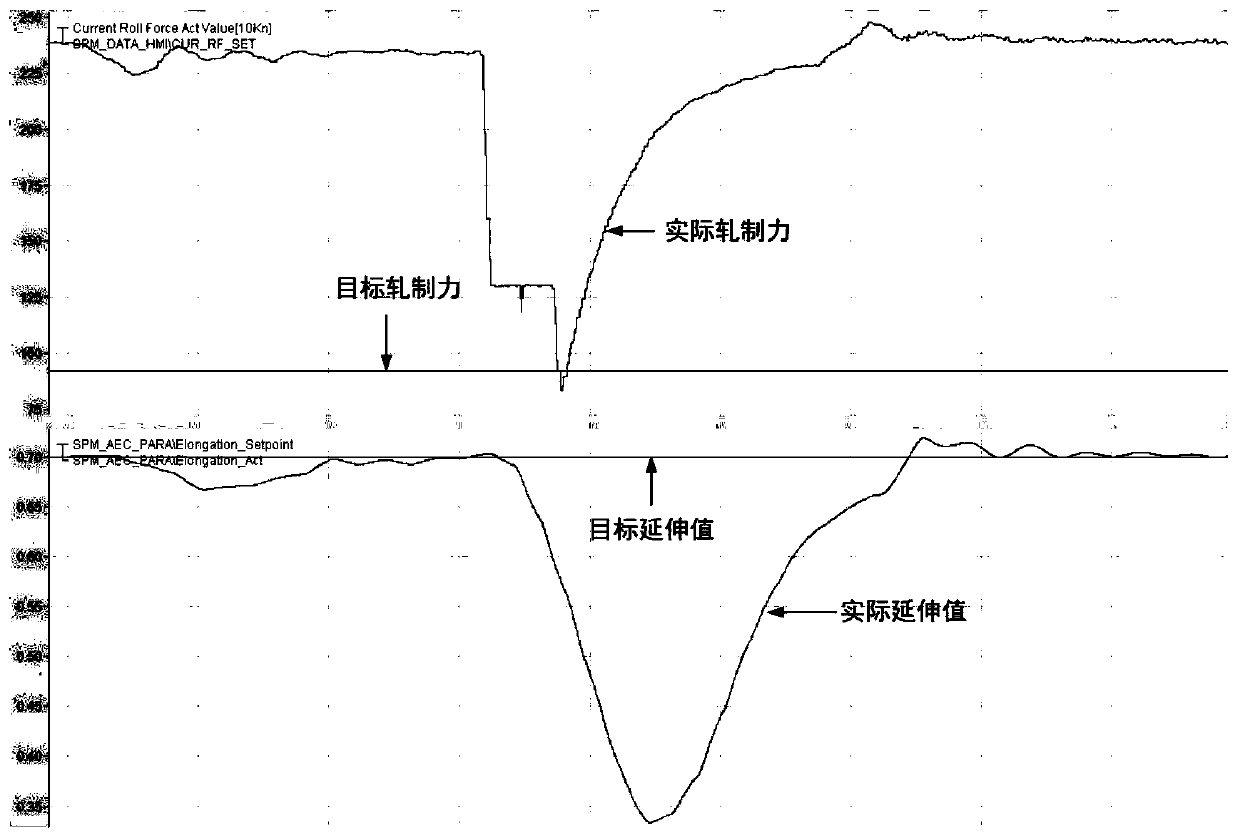

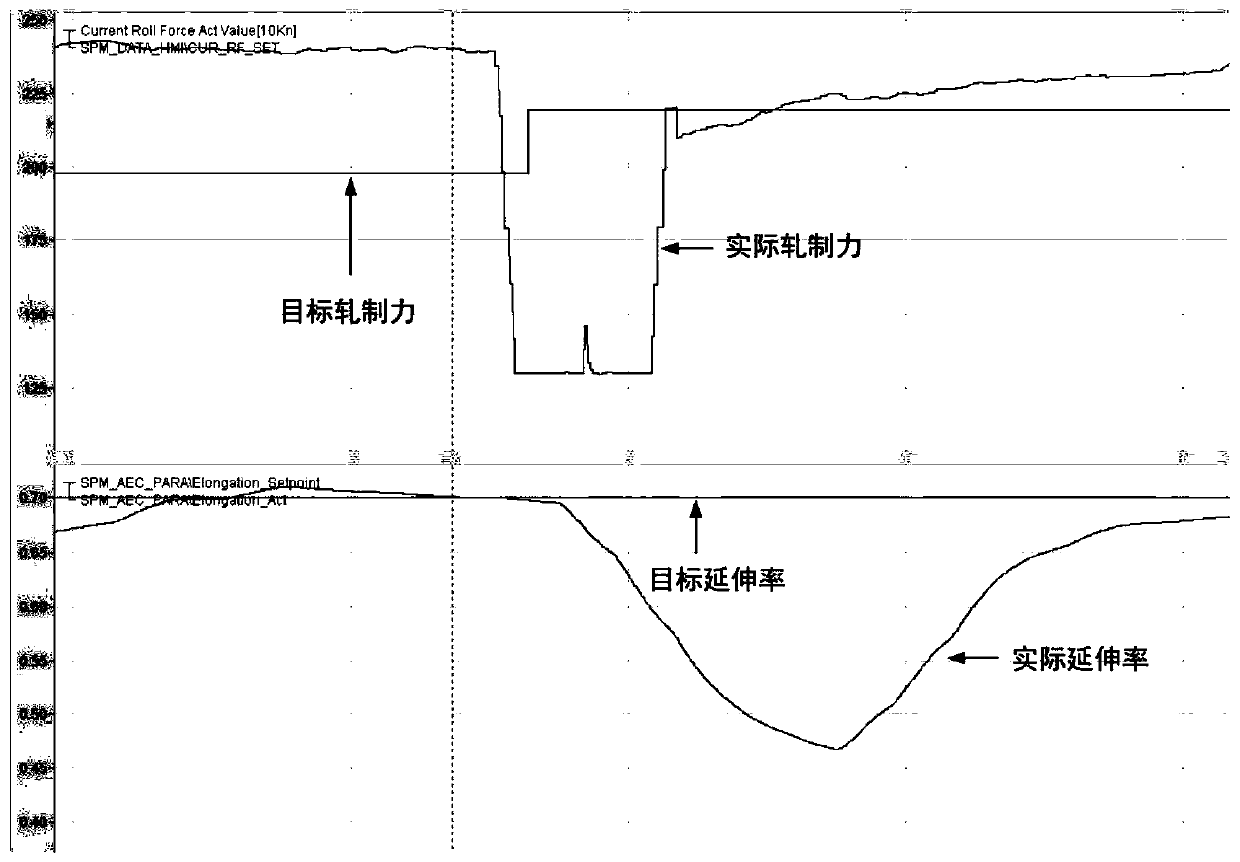

[0030] to combine figure 1 As shown, taking the production process of a 590CQ steel strip with a thickness of 1.41mm, a width of 1302mm, and a target elongation of 0.7% as an example, the distance between the welding seam and the position of the tempering machine is tracked, and the front tensioning of the tempering machine is used to track the distance between the welding seam and the position of the tempering machine. The tight roller corrects...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com