Tensile strength 540Mpa grade dual phase steel plate and its production method

A technology with a tensile strength of 570mpa, applied in the field of steel rolling, to achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

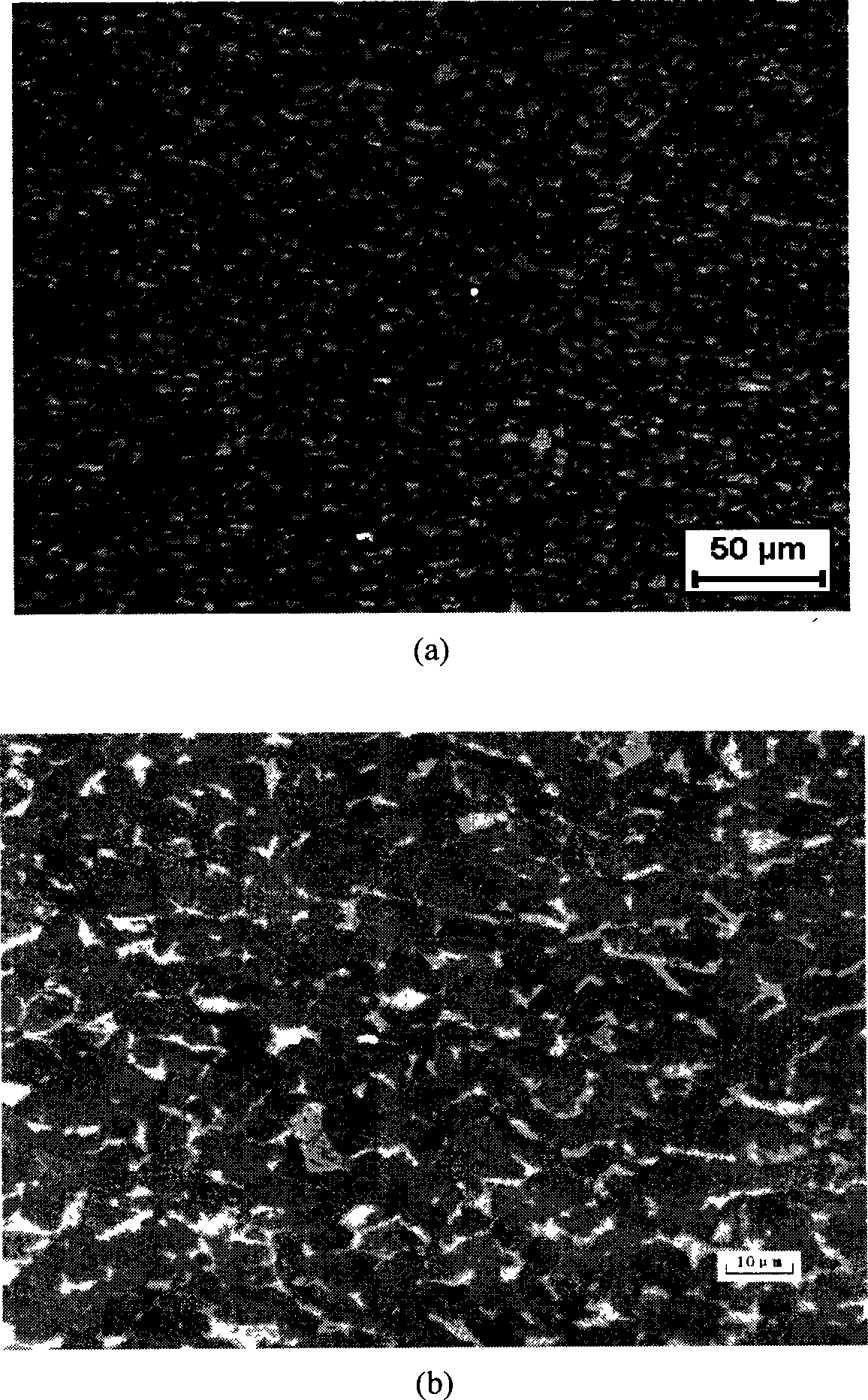

Image

Examples

Embodiment Construction

[0013] The steel with the chemical composition shown in Table 1 is selected as the raw material, and the continuous casting and rolling thin slab size is 60-80 mm (thickness) × 1250 mm (width) × 8000 mm (length). The continuous cast thin slab is soaked in a tunnel furnace with a length of 100m, and then rolled by a hot continuous rolling mill. The starting and finishing temperatures are controlled, and rapid cooling is carried out after rolling. The laminar cooling process is adopted to control the cooling rate and The final cooling temperature, and then coiling, the thickness of the steel plate is controlled to be 2.5-6mm. The cooling process is shown in Table 2, and the mechanical properties and structure scores are shown in Table 3.

[0014] Ingredient number

[0015]

[0016]

[0017] where: R e -Yield strength: R m - Tensile strength; A 50 -Total elongation after fracture (gauge length 50mm); the implementation data corresponding to the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com