Control system for suppressing impact speed drop and torsional oscillation of rolling mill transmission system

A technology of control system and transmission system, applied in rolling mill control device, roll speed control, metal rolling, etc., can solve the problems of large dynamic speed drop, inability to suppress speed oscillation, etc., to reduce dynamic speed drop, simple structure, restraint The effect of torsional vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

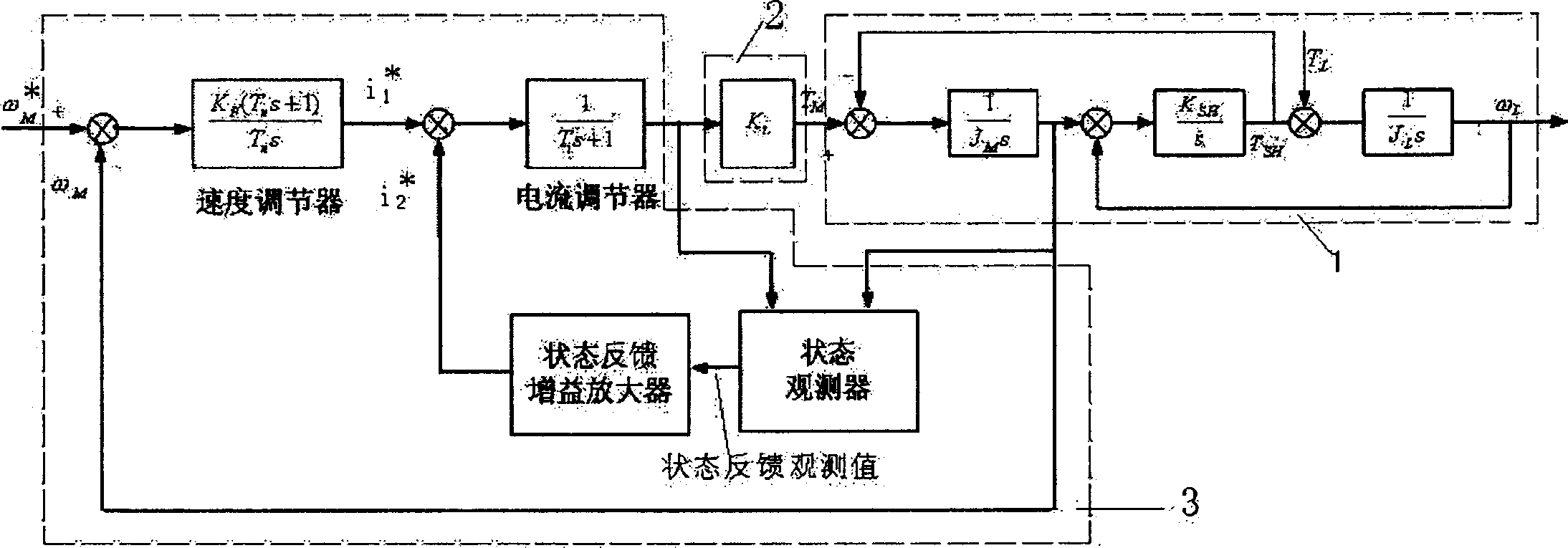

[0024] Such as figure 2 As shown, the rolling mill speed control system used in this patent includes a rolling mill drive two-mass elastic system, a control system and a power conversion system. The hardware of the control system is a dedicated processor board, and the software function structure is shown in the dotted frame of the control part in the figure. Motor speed given value (ω * ) and the speed detection value (ω) are input to the speed regulator, and its output is the torque current given value i 1 * ;Motor current detection value i M and the motor speed detection value are input to the load observer, and the observer calculates the load torque observation value and the observed value of torsional velocity difference The observed value is calculated by the state feedback gain amplifier to form the compensation current given value i 2 * (used to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com