Vertical pressure-bearing double-cycle all-plastic water tank liner

A double-circulation and water tank technology, applied in solar thermal power generation, fluid heaters, heating devices, etc., can solve the problems of short life and high price of enamel liners, and achieve the effects of saving metal raw materials, long life and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

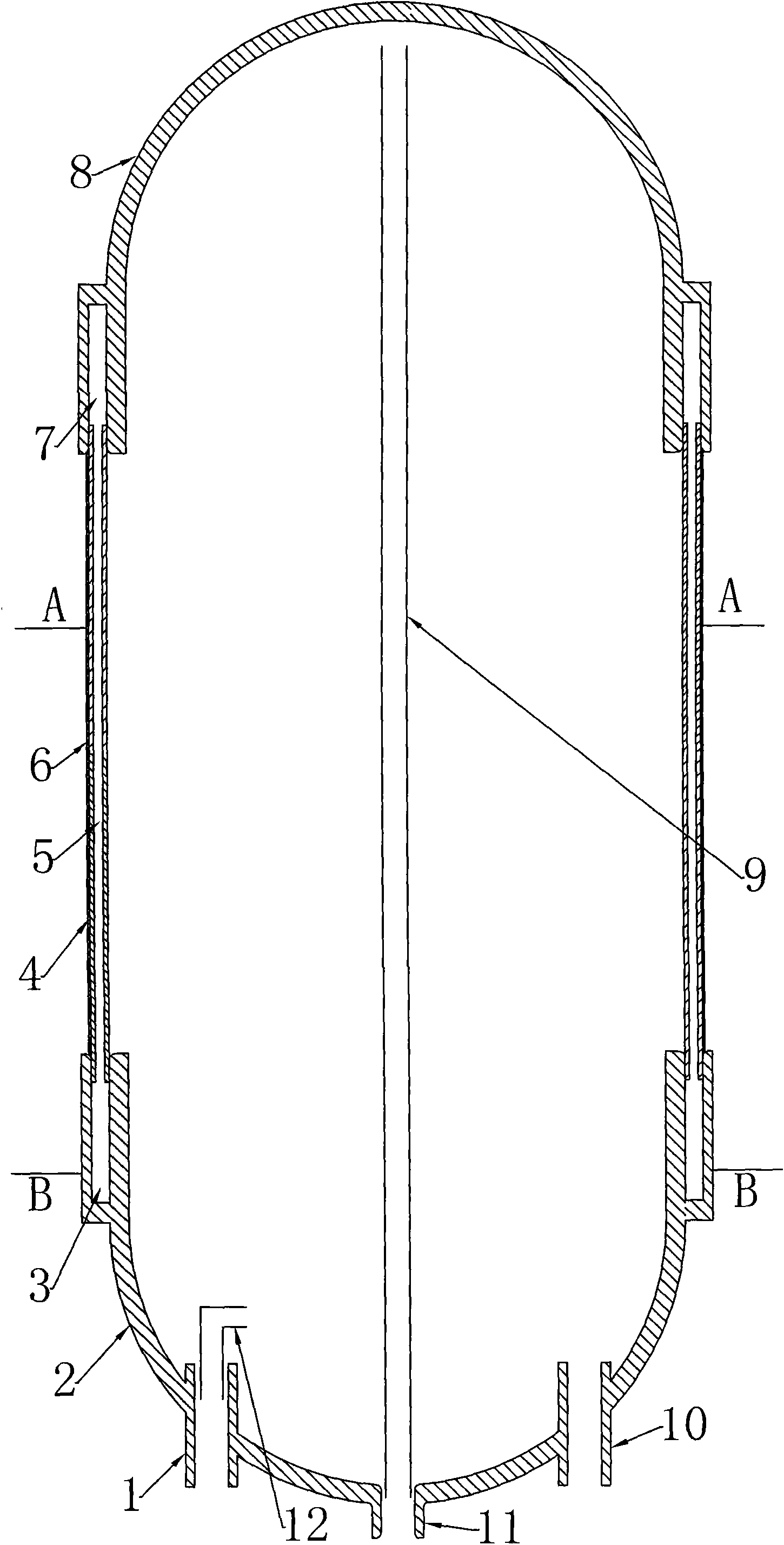

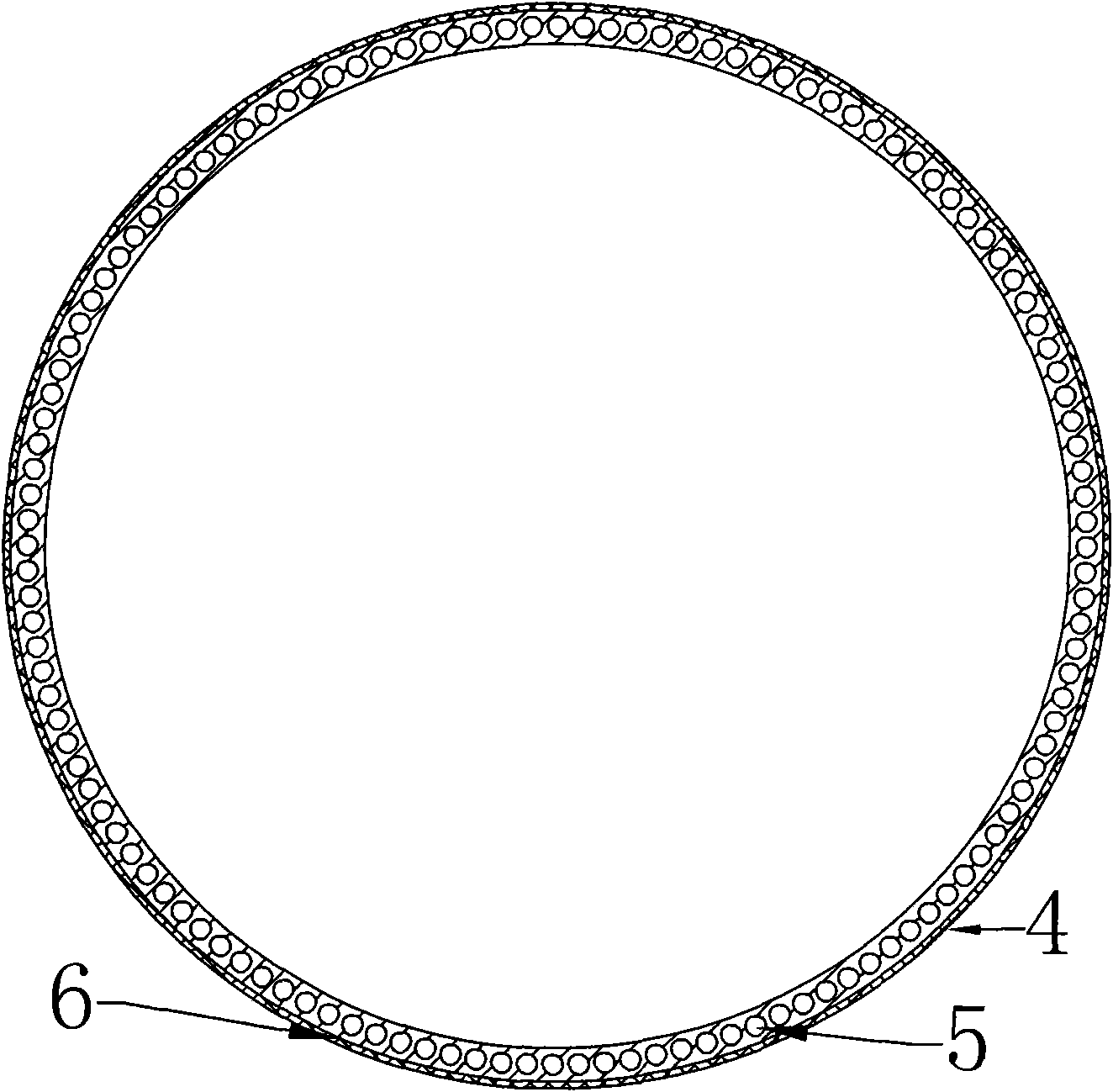

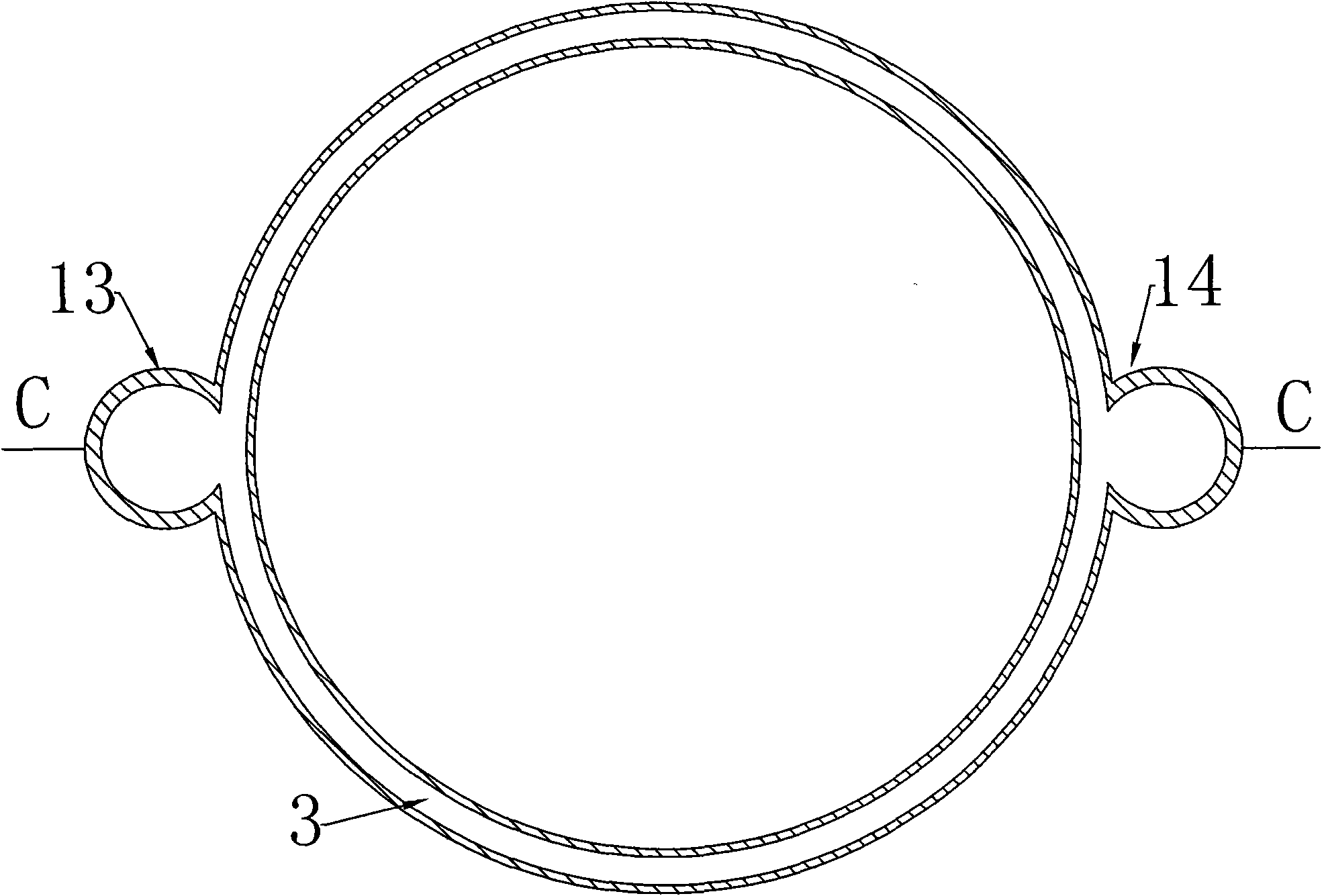

[0023] figure 1 , figure 2 , image 3 , Figure 4 A structural form of the liner of a vertical pressurized double-circulation all-plastic water tank is jointly described. The liner is made of polymer material, or modified polymer material, or reinforced polymer, or composite polymer material; the end cover 2 has a cold water inlet pipe 1, a hot water outlet pipe 11, an electric heater installation pipe 10, and a circulation Pipe 13, circulation pipe 14; exhaust pipe 15 on the end cover 8; the end cover and the pipes on the end cover are integrally injection molded by injection molding process; the upper end of the cold water inlet pipe is hot-melt connected with an elbow 12; the hot water outlet pipe 11 The upper end is hot-melt connected with a hot water pipe 9; the hot water pipe 9 communicates with the upper part of the water tank; the outer wall of the water tank 4 has a reinforcement layer 6, the reinforcement layer is outside the wall of the water tank wall, or insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com