Hardware part end face grinding clamp

A technology for end face grinding and hardware parts, which is applied in the direction of grinding workpiece supports, grinding drive devices, grinding machine parts, etc. The effect of preventing excessive heat, increasing water spray pressure, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

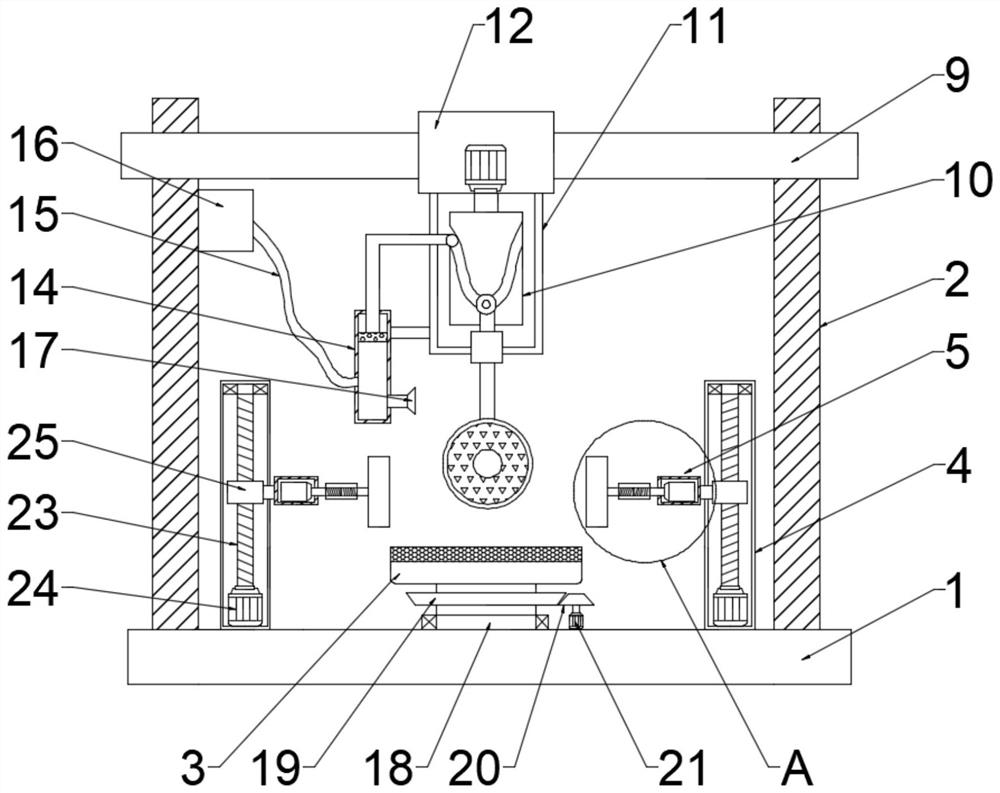

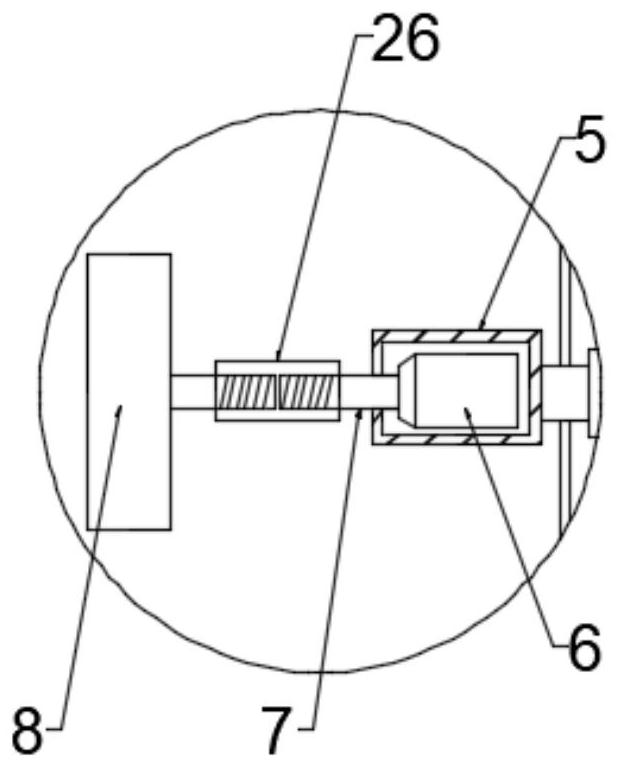

[0023] see figure 1 and 2 , in an embodiment of the present invention, a fixture for end surface grinding of hardware parts, comprising a base 1, support columns 2 are symmetrically arranged on both sides above the base 1, and a workbench 3 is arranged at the center of the base 1, and the workbench 3, mounting columns 4 are arranged on both sides, and the side of the mounting column 4 close to the workbench 3 is connected with an installation chamber 5, and a cylinder 6 is installed in the installation chamber 5, and the cylinder 6 is connected with a telescopic rod 7, and the telescopic One end of the rod 7 is connected with a fixed plate 8; a support plate 9 is fixedly installed horizontally above the support column 2, an electric slide 12 is arranged in the middle of the support plate 9, and a transmission compartment 11 is arranged below the electric slide 12, so The transmission chamber 11 is provided with a lifting device 10, a grinding plate 13 is fixedly connected to ...

Embodiment 2

[0025] In this embodiment, a rotating column 18 is connected to the bottom of the workbench 3, and a driven bevel gear 19 is installed on the rotating column 18, and a driving bevel gear 20 is meshed on one side of the driven bevel gear 19. The first driving motor 21 is connected to the bottom of the bevel gear 20, and the rotation of the first driving motor 21 drives the driving bevel gear 20 to mesh with the driven bevel gear 19, and drives the workbench 3 to rotate, which is convenient for processing different surfaces of the workpiece.

[0026] In this embodiment, an anti-slip rubber pad 22 is installed on the surface of the workbench 3 to improve the fixing effect of parts on the surface of the workbench 3 .

[0027] In this embodiment, a screw rod 23 is arranged inside the mounting column 4, a rotating motor 24 is connected to the bottom of the screw rod 23, and a lifting slider 25 is threaded on the screw rod 23, and the lifting slider 25 is The side is fixedly connecte...

Embodiment 3

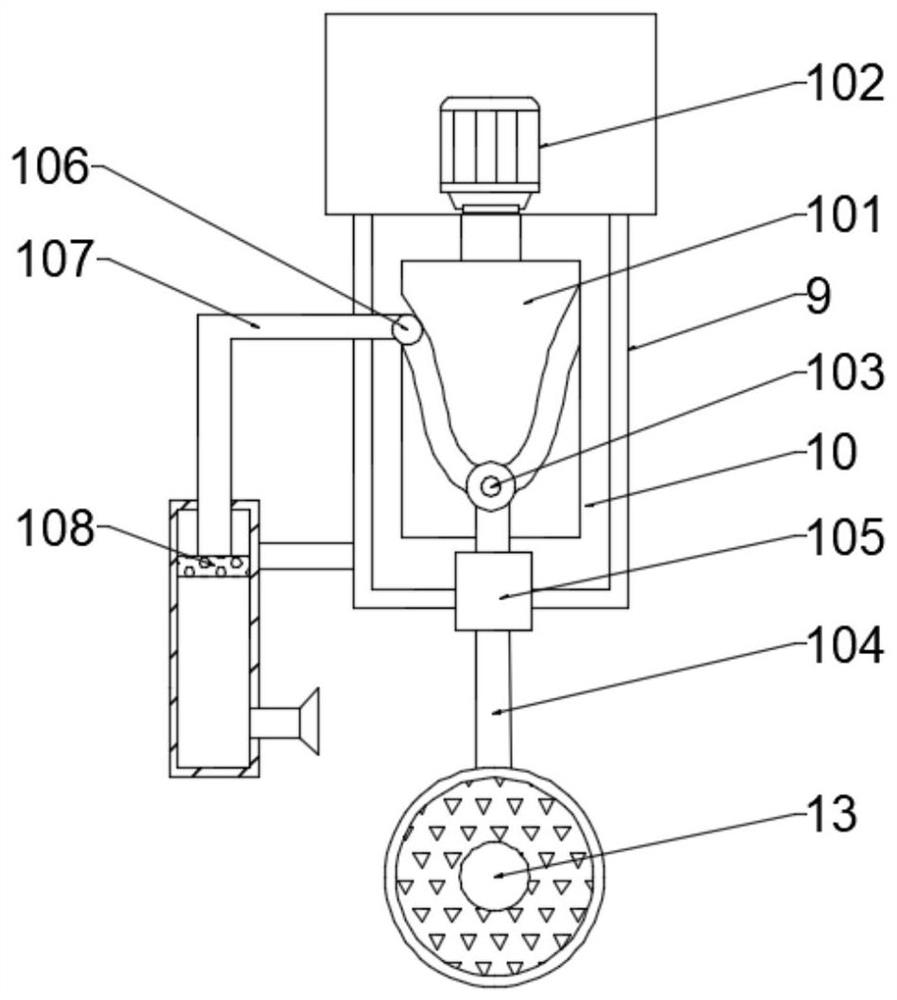

[0029] see image 3 , in this embodiment, the lifting device 10 includes a cylindrical cam 101, a second driving motor 102 is connected above the cylindrical cam 101, and a first transmission rod 103 is slidably connected in a chute on the surface of the middle part of the cylindrical cam 101, so The first transmission rod 103 is connected with a lifting rod 104, the bottom of the lifting rod 104 is connected with the grinding plate 13, and the rotation of the second driving motor 102 drives the cylindrical cam 101 to rotate. When the cylindrical cam 101 rotates, the chute on the surface and the The first transmission rod 103 cooperates to realize the up and down movement of the lifting rod 104, thereby driving the grinding plate 13 to grind up and down intermittently, which improves the grinding effect on the workpiece.

[0030] In this embodiment, a second transmission rod 106 is slidably connected to the outer chute on one side of the cylindrical cam 101, a piston rod 107 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com