All-plastic straight pressure-bearing double-cycle solar water heater

A technology for solar water heaters and solar collector tubes, applied in the directions of solar collectors, solar thermal storage, solar thermal energy, etc., can solve the problem of inability to fundamentally eliminate scaling, easy scaling at the condensing end, heat transfer efficiency, and lower system reliability. and other problems, to achieve the effect of saving non-ferrous metal raw materials, good thermal insulation performance, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

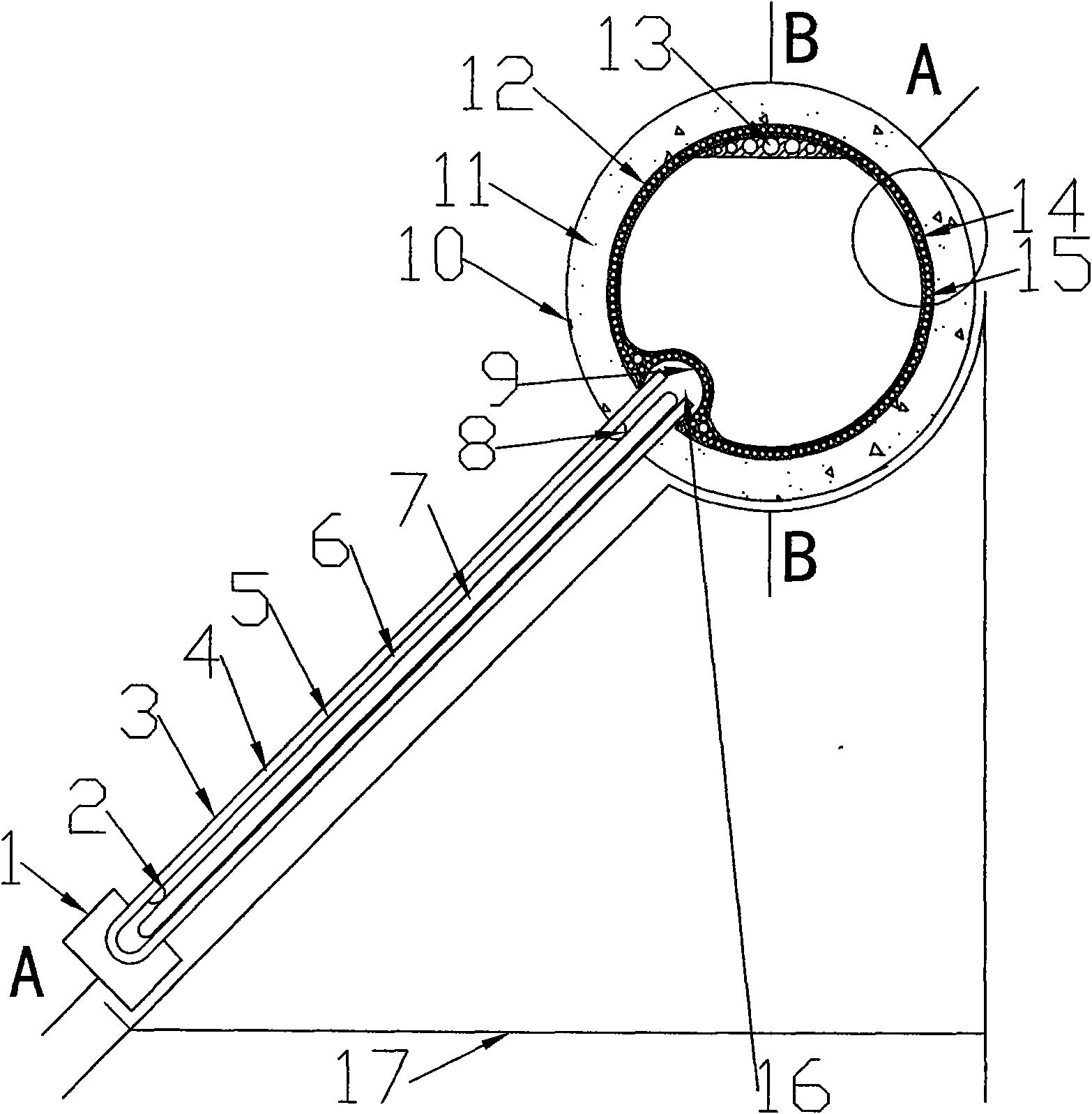

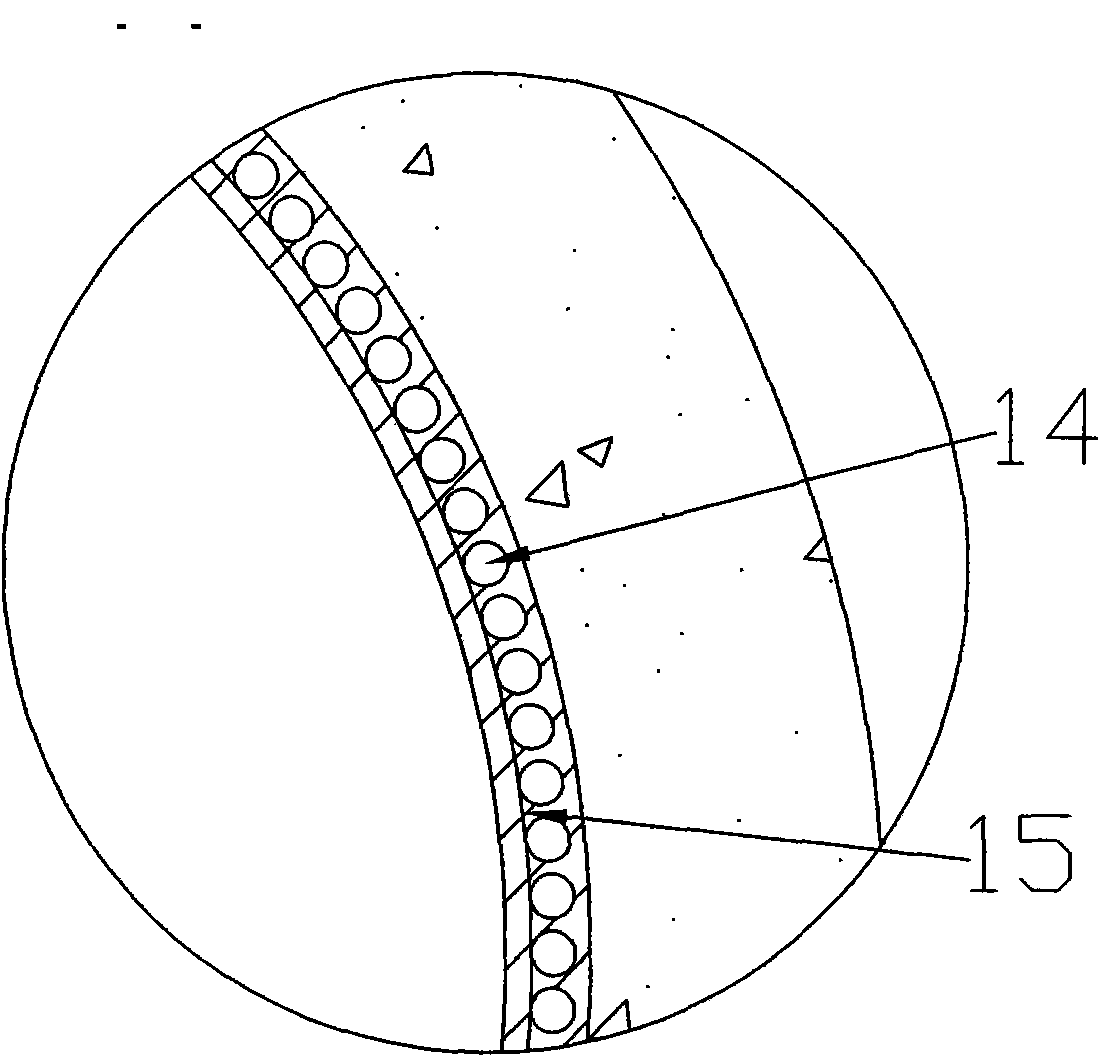

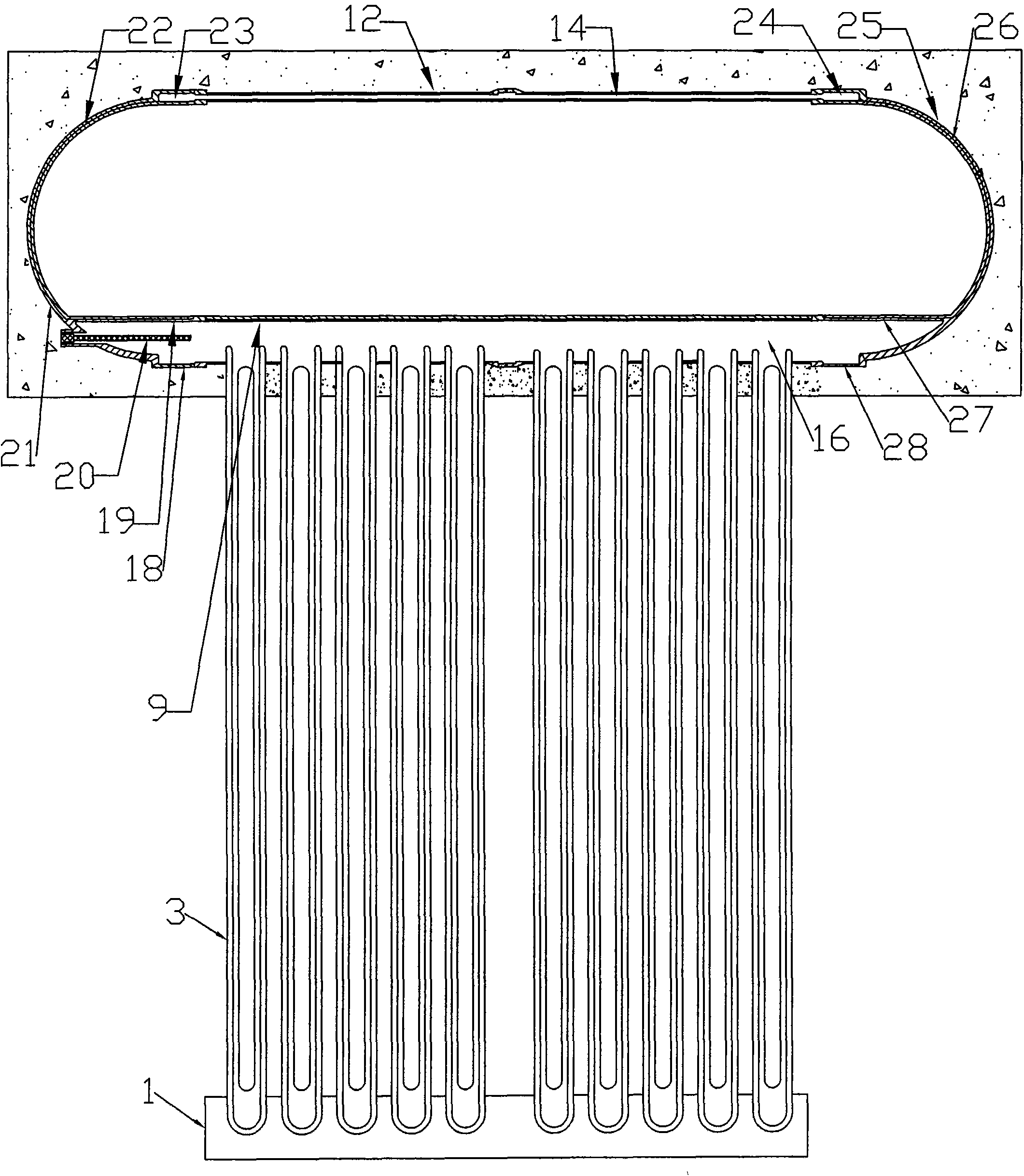

[0024] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A structural form of an all-plastic in-line pressurized double-circulation solar water heater is jointly described. The inner tube fixing card 2 and the inner tube fixing card 8 bias and fix the inner tube 7 on the lower wall of the heating chamber 6; The coating layer of the glass three-chamber vacuum solar heat collector tube; there are multiple vacuum tube insertion holes on the wall of the water tank, and the vacuum tube insertion holes are covered with rubber rings, and the upper end of the offset all-glass three-chamber vacuum solar heat collector tube 3 is inserted into the water tank wall. In the hole of the rubber ring, the lower end is inserted into the hole of the tail box 1; the water tank 12 is fixed in the middle of the shell 10 by the insulation layer 11; the water tank 12, the end cover, the insulation layer 11, and the shell 10 together form the heat preservation water tank; The all-glass thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com