High-precision etching production system and method for flexible PCB

A PCB board and production method technology, applied to flexible printed circuit boards, removal of conductive materials by chemical/electrolytic methods, sequence of processing steps, etc., can solve the difficulty of debugging process parameters, large amount of side erosion of fine lines, and circuit Problems such as poor microscopic morphology, to achieve the effect of simplifying process parameter debugging, improving production efficiency and yield, and difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to fully illustrate the technical content of the present invention, the technical solutions of the present invention will be further introduced and described below in conjunction with specific implementation methods and accompanying drawings.

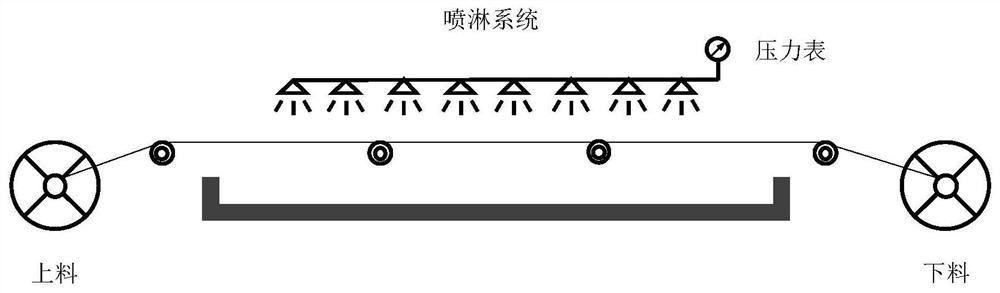

[0044] figure 1 It is a schematic diagram of the production line structure of the traditional etching process for fine PCB boards, refer to figure 1 , the traditional etching process uses the same process production parameters for the entire spray equipment, that is, the spray pressure, spray temperature, solution concentration and other parameters are the same for the entire production line, which can easily cause uneven etching of the line, serious side erosion, etc. The problem greatly affects the accuracy and quality of the fine PCB board.

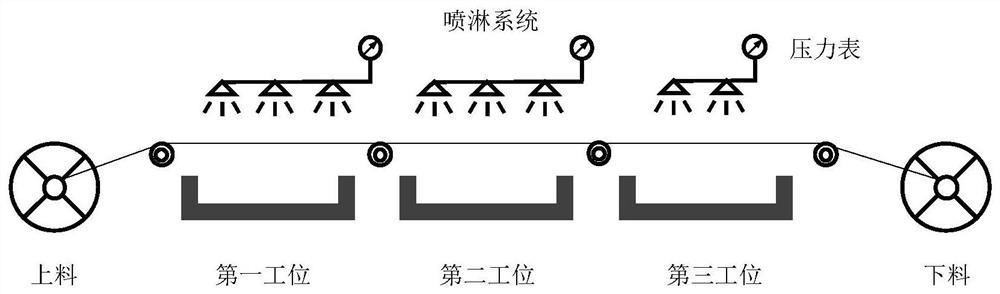

[0045] figure 2 It is a structural schematic diagram of a high-precision etching production system for flexible PCB boards proposed by the present invention, including a PCB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com