Semiconductor device and forming method thereof

A technology of semiconductors and devices, which is applied in the field of semiconductor devices and their formation, and can solve the problems that the suspended part of the passivation layer is prone to damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

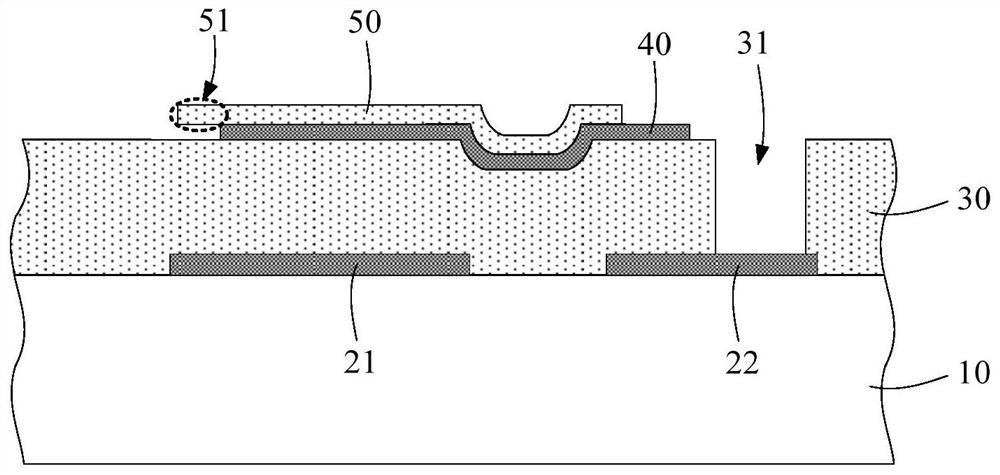

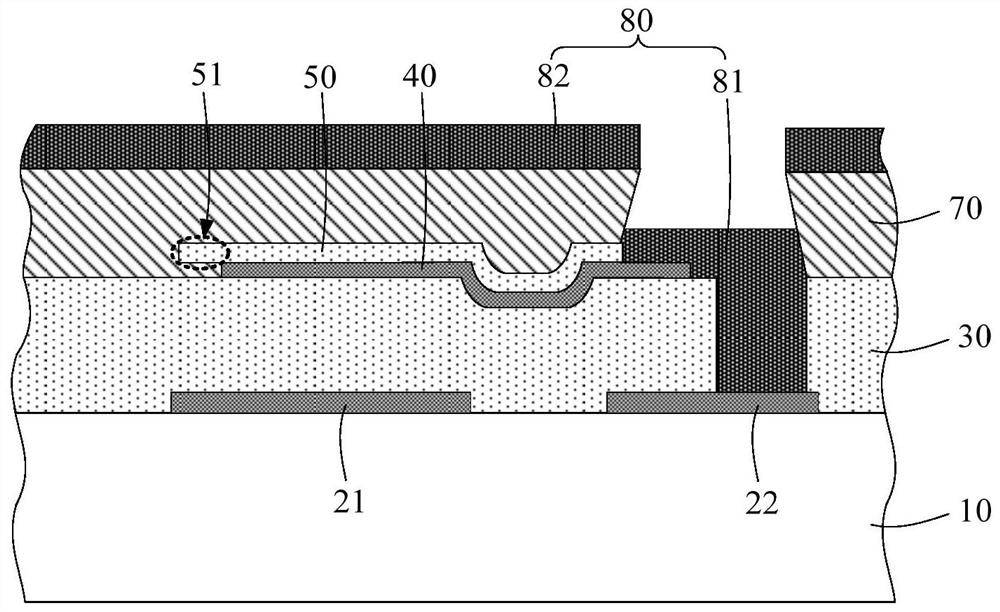

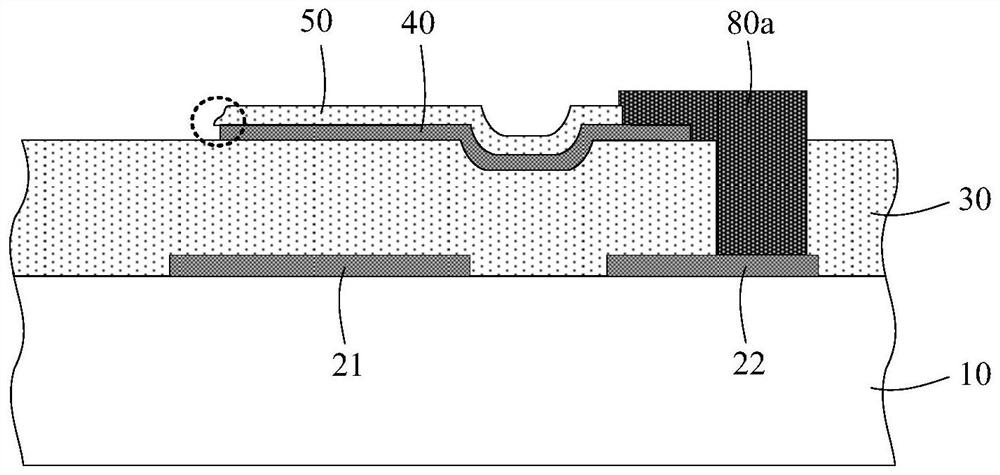

[0053] As mentioned in the background, in the current manufacturing method of semiconductor devices, when the photoresist layer is removed based on high-intensity spraying pressure, the suspended part of the passivation layer is easily damaged. Based on this, even if the spraying pressure is reduced to avoid the damage of the suspended part, however, the photoresist layer will not be completely removed at this time.

[0054]Therefore, the present invention provides a method for forming a semiconductor device, so as to ensure that the photoresist layer can be completely removed and prevent the problem of damage to the floating portion in the passivation layer. For example reference figure 2 As shown, the forming method of the semiconductor device includes:

[0055] Step S100, providing a substrate, on which a lower electrode layer and an extraction electrode are formed, and a piezoelectric material layer, an upper electrode layer, and a passivation layer are sequentially form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com