Pile bottom sediment ultra-high-pressure replacement slurry spraying structure and construction method thereof

A technology of ultra-high pressure and grouting, applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of unsatisfactory treatment effect of pile bottom sediment, reduce the ultimate bearing capacity of pile foundation, and no good sediment, etc. Wide stratum, simple structure and short construction period

Pending Publication Date: 2019-08-20

SHANGHAI ZHIPING FOUNDATION ENG CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most of the methods for controlling the sediment at the bottom of the hole are to use the method of "one cleaning" and "two cleaning" to deal with the sediment at the bottom of the hole before pouring concrete. However, there is no good method to control the sediment after pile inspection deal with

[0003] The existing technology is not ideal for the treatment of pile bottom sediment, especially the grouting process cannot be carried out after the pile detection, there are weak points of the pile foundation, which greatly reduces the ultimate bearing capacity of the pile foundation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

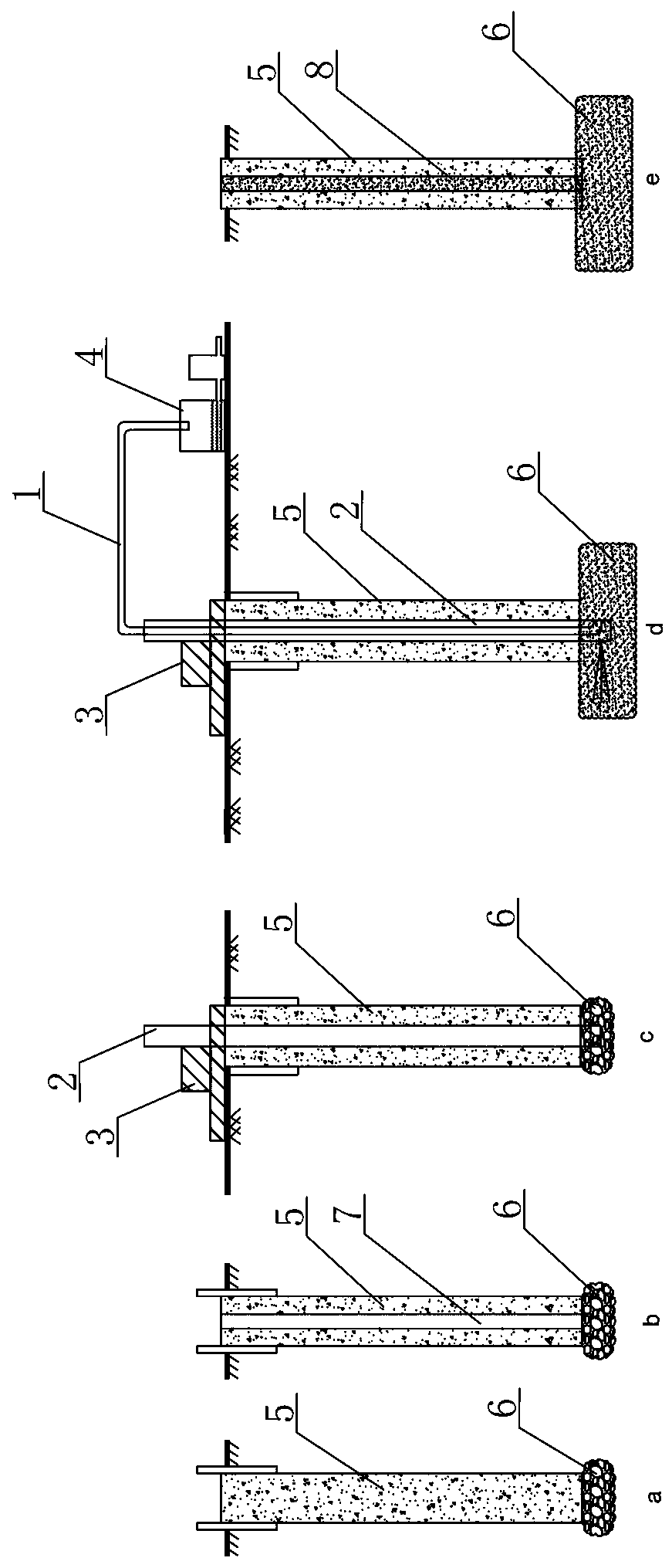

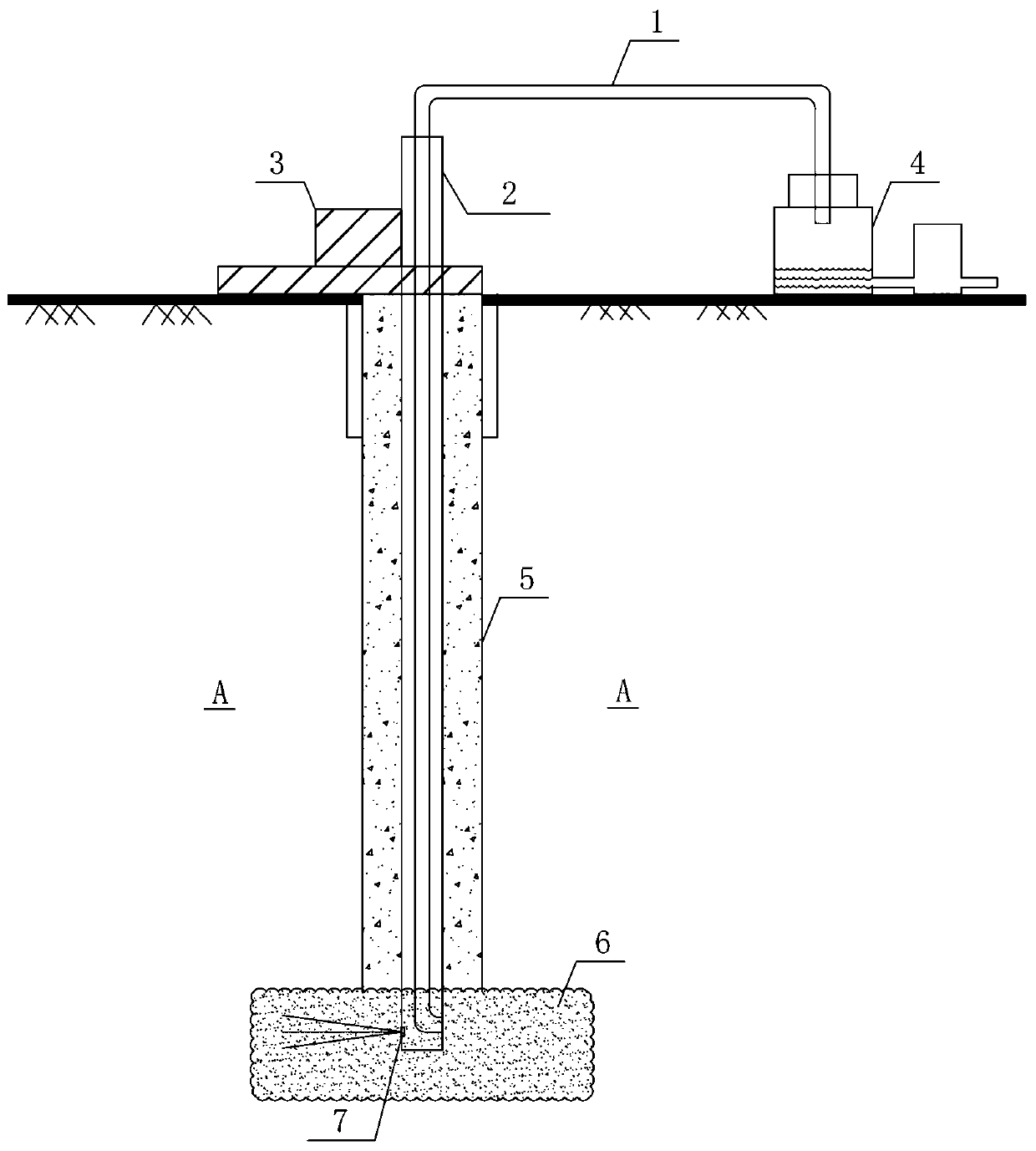

[0024] a. Construction of cast-in-place piles

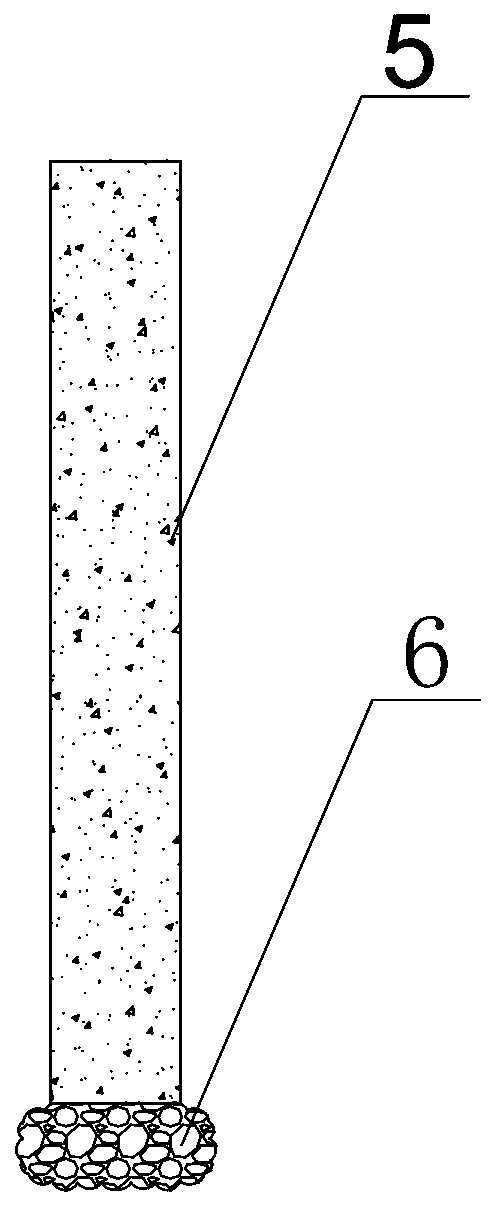

[0025] See attached figure 2 a. The pile driver is in place. According to the design requirements, first construct the bored pile 5. After drilling into the hole, hang the reinforcement cage and the lower conduit, then pour concrete, and gradually pull out the conduit. .

[0026] b. Drilling and coring

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a pile bottom sediment ultra-high-pressure replacement slurry spraying structure and a construction method thereof. The structure is characterized in that the bottom of a pouring pile is arranged on a cement soil swelling structure which is formed by slurry spraying and enhances the strength of pile side soil and pile end soil. The construction method of the structure comprises the steps of construction of the pouring pile, drilling and core taking, replacement slurry spraying, core taking grouting and the like. Compared with the prior art, the structure is simple, construction is convenient, the bearing force of the pile is effectively increased, the pouring pile is a rigid pile and is arranged in a flexible rotary stirring pile, no mud is generated in the construction process, the construction cost is further reduced, and the structure is green and environmentally friendly.

Description

technical field [0001] The invention relates to the technical field of pile foundation engineering, in particular to an ultra-high pressure replacement spraying grouting structure for pile bottom sediment and a construction method thereof. Background technique [0002] Bored piles are widely used in various construction projects due to their advantages such as wide application range, high single pile bearing capacity, low construction noise, small vibration and low unit price. With the increasing number of high-rise buildings, the requirements for the bearing capacity of pile foundations are also getting higher and higher. Due to the particularity of the construction technology of the bored pile, its bearing capacity is greatly affected by factors in the construction, especially the sediment layer at the bottom of the hole seriously affects the bearing capacity of the pile. Pile bottom sediment refers to the sediment left by the sedimentation or collapse during the drilling...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02D5/34E02D15/04E02D13/08

CPCE02D5/34E02D15/04E02D13/08

Inventor 刘忠秋胡宝山刘喜林

Owner SHANGHAI ZHIPING FOUNDATION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com