Static dust collection system

A technology of electrostatic precipitator and electrostatic precipitator, which is applied in the field of electrostatic precipitator system, can solve the problems of energy waste, electric field distortion, and excessive emission, and achieve the effects of reducing energy consumption, improving automation level, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

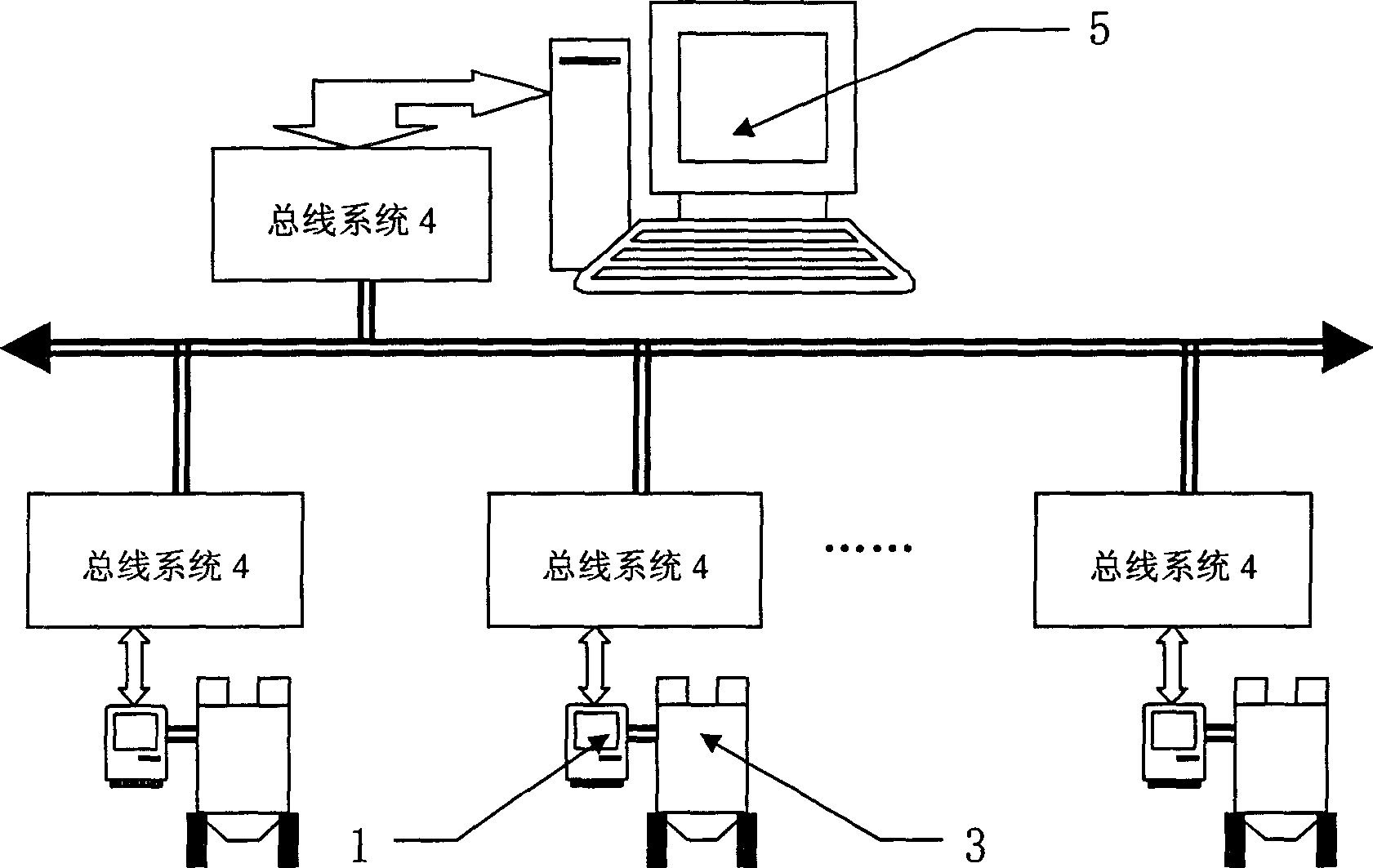

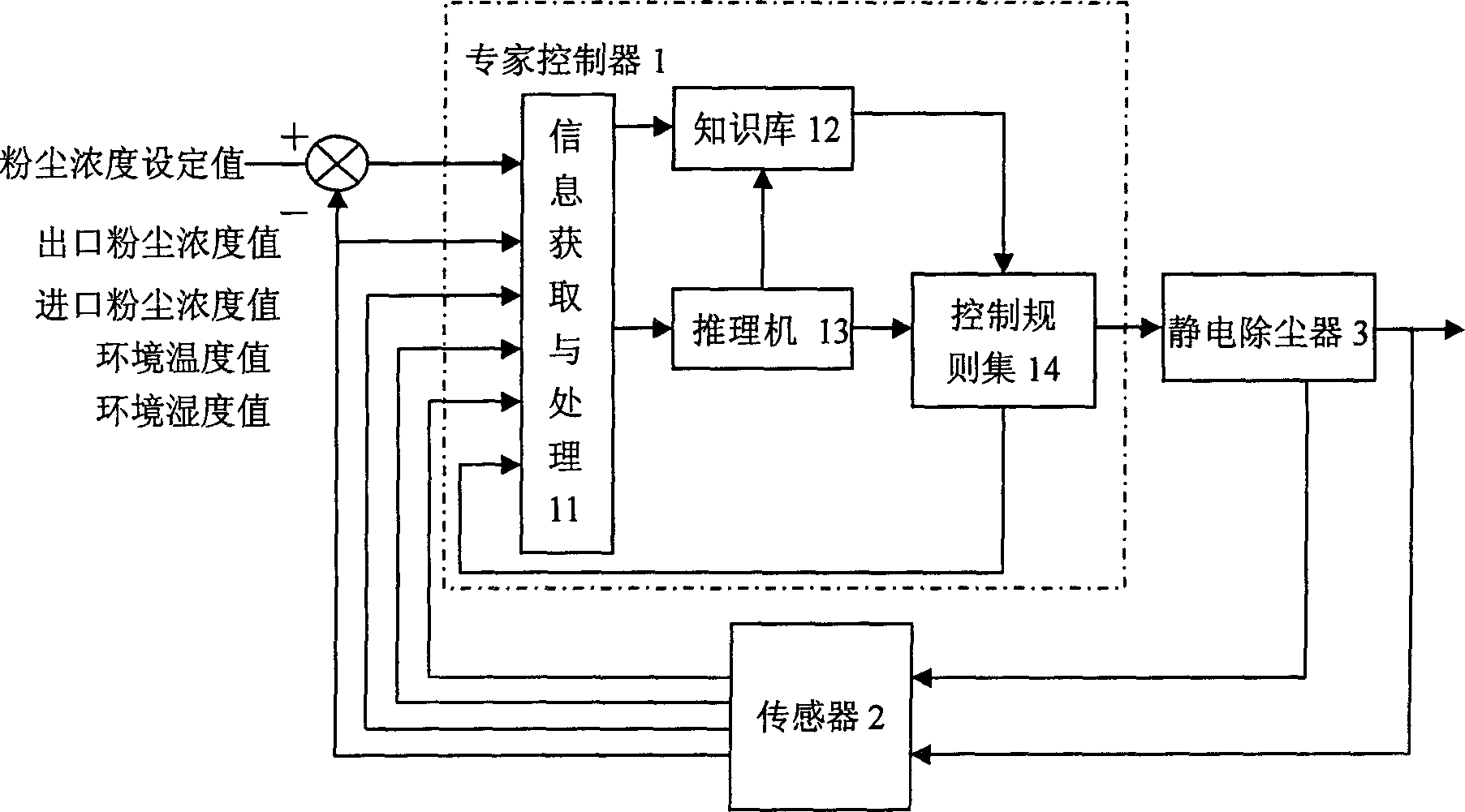

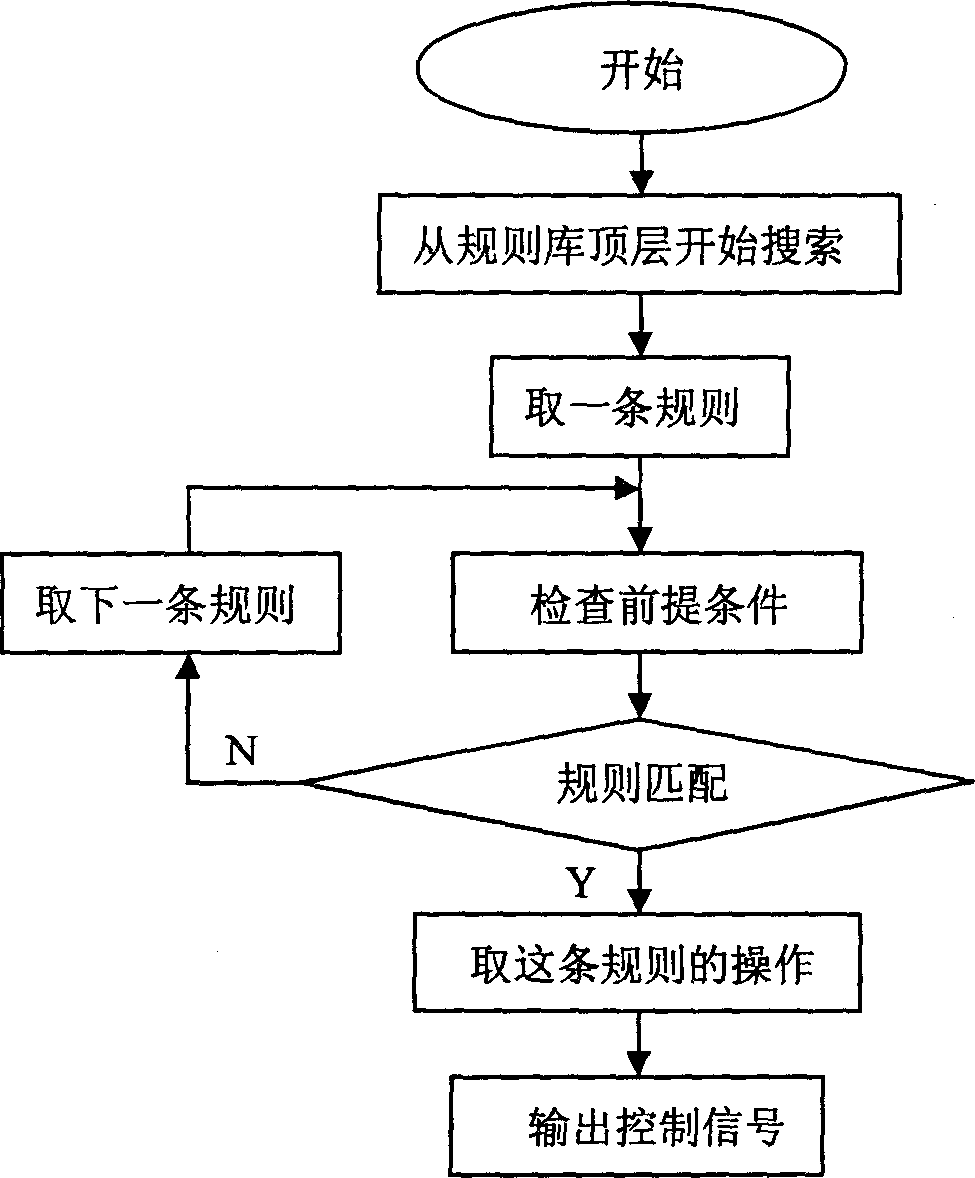

[0015] refer to figure 1 , an electrostatic precipitator system, including an electrostatic precipitator 3, an expert controller 1 and a sensor 2 arranged in the electrostatic precipitator 3, the output of the sensor 2 is connected to the input end of the expert controller 2, and the output end of the expert controller 1 is connected to the electrostatic precipitator The electric field voltage control circuit of 3 is connected; the sensor 2 detects the corresponding data in the electrostatic precipitator 3 and sends it to the expert controller 1 for analysis and processing, and generates a control signal to control the electric field voltage control circuit of the electrostatic precipitator 3, and then adjusts the electrostatic precipitator The dust removal intensity of 3 keeps the dust concentration at the outlet stable at the set value.

[0016] The structure, working principle and process of the electrostatic precipitator system are described in detail below.

[0017] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com