Large tunnel dust removal plant and dust removal method thereof

A technology for dust removal equipment and tunnels, which is used in mining equipment, dust prevention, earth-moving drilling, etc., can solve the problems of wasting water, general treatment effect, and high cleaning cost, and achieve the effect of convenient transportation, low cleaning cost and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

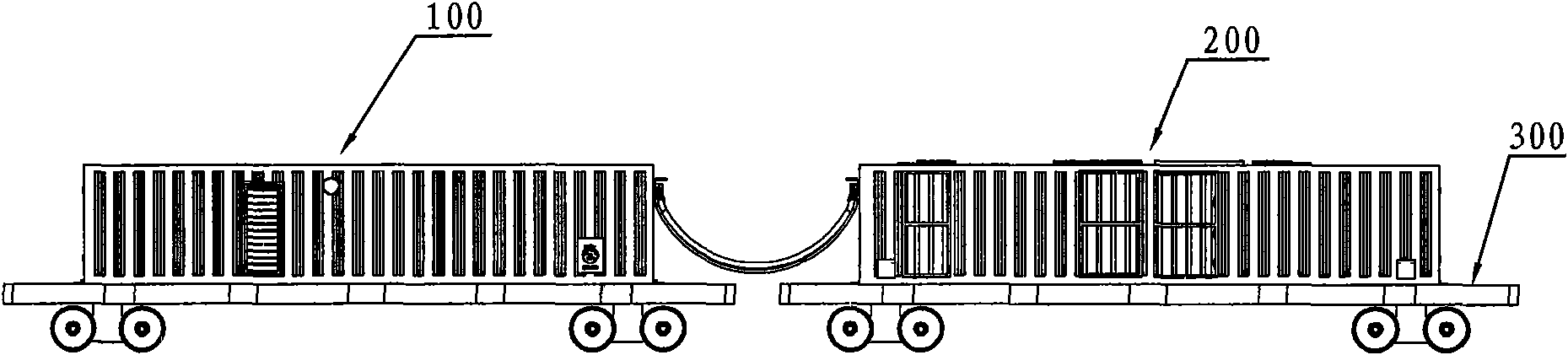

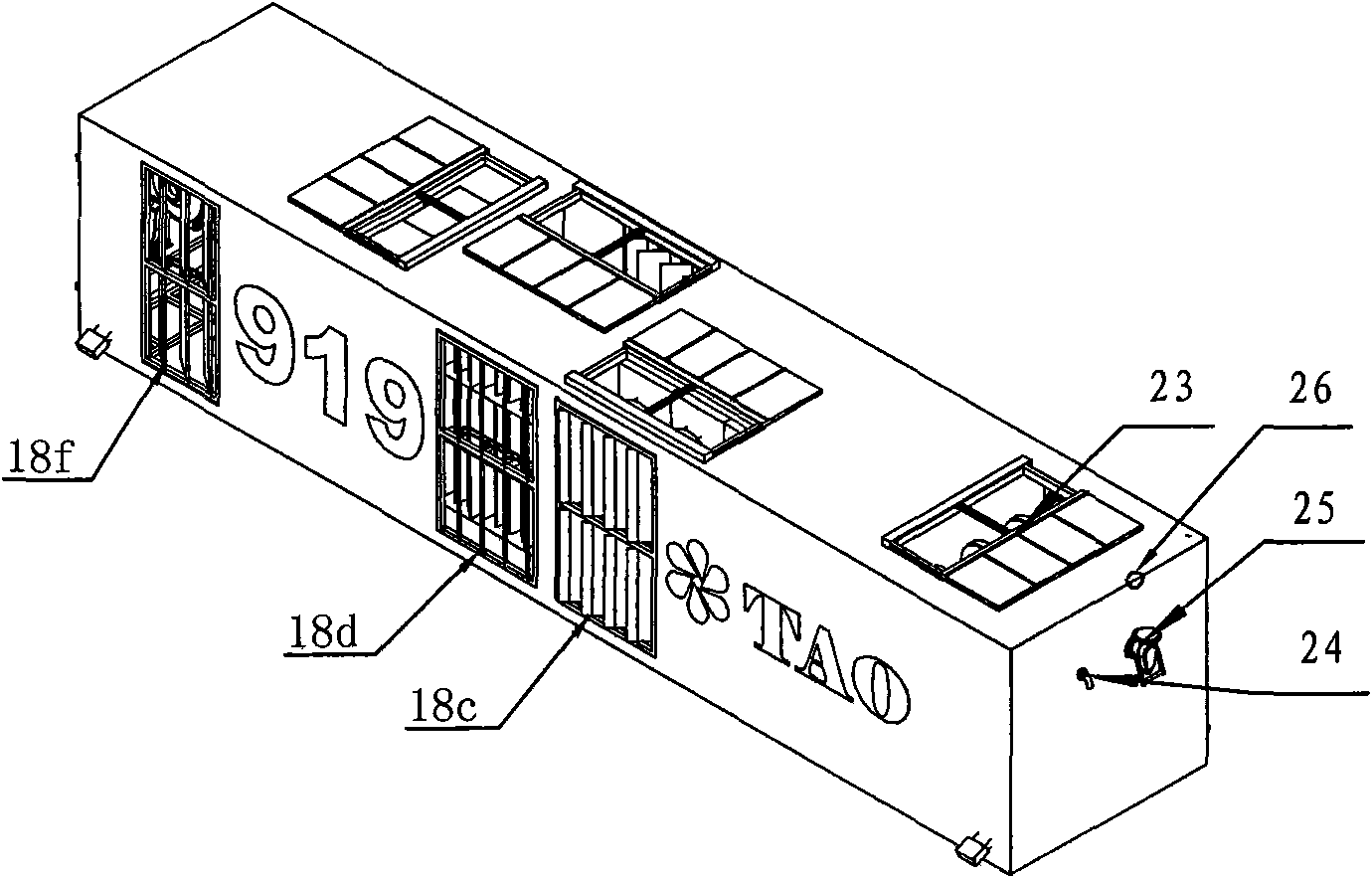

[0029] see figure 1 The embodiment of the present invention provides a large-scale tunnel dust removal equipment, including a dust removal power control group 100 and a dust removal operation group 200, which are respectively arranged in two containers, and the two containers are connected by a connector; the two containers are placed on a flatbed truck 300.

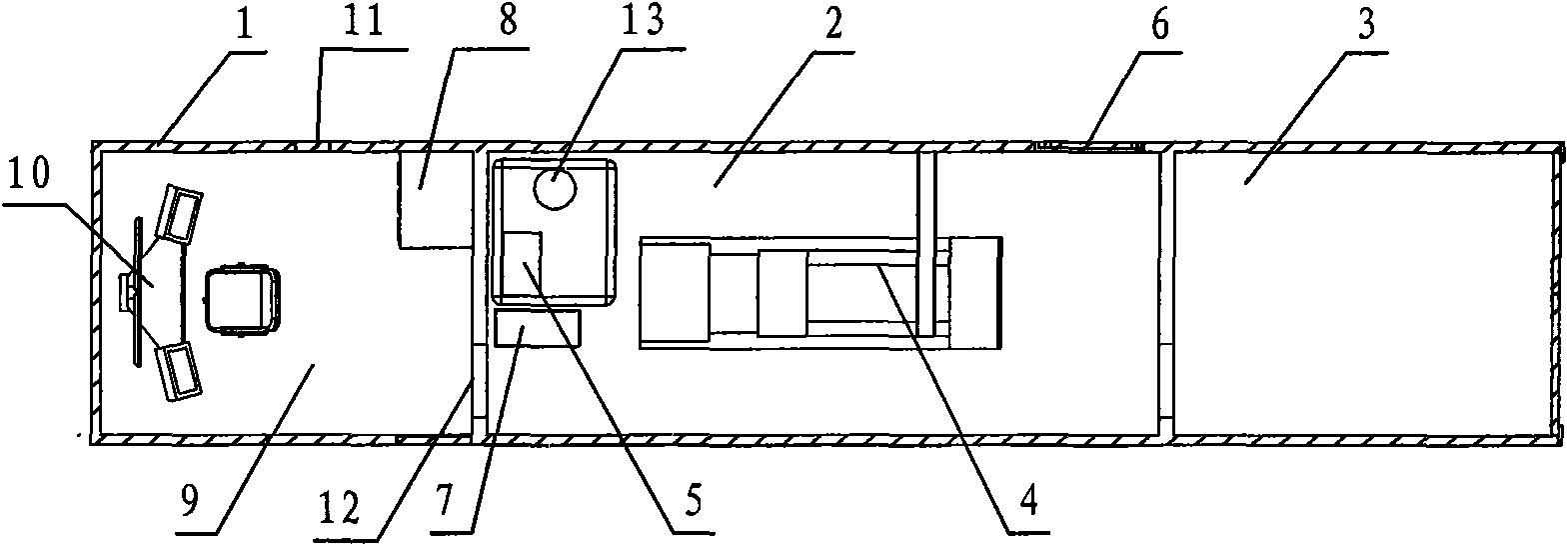

[0030] see figure 2 , the dust removal power control group includes a power distribution and control warehouse 9, a power warehouse 2 and a reserve warehouse 3 arranged in sequence in the container 1; a console 10, a generator power distribution cabinet 8 and an escape door are arranged in the power distribution and control warehouse 9 11. The power warehouse 2 is provided with a generator 4 for power distribution cabinet 8, an auxiliary generator 5 and an air c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com