Bearing washer

A bearing cleaning and cleaning room technology, which is applied in the direction of dust removal, cleaning methods and tools, cleaning methods using liquids, etc., can solve the problems that ordinary bearing cleaning machines cannot be effective, large-size bearings are troublesome to operate, and the operation labor intensity is low. Achieve the effects of low labor intensity of operation, improvement of product quality and service life, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

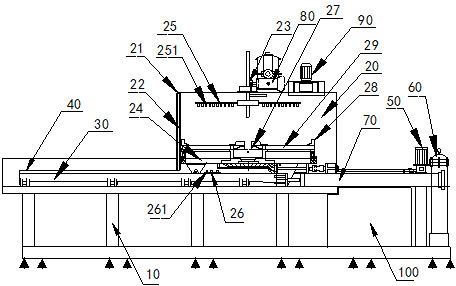

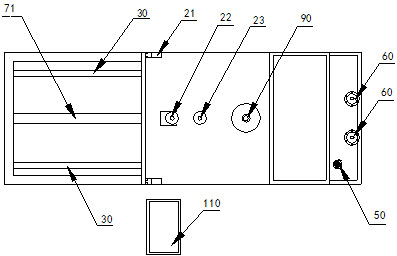

[0025] figure 1 , figure 2 , image 3 In the shown embodiment, a bearing cleaning machine includes a main workbench 10, a cleaning chamber 20 installed on the main workbench 10, a spray pump and a transmission motor 80, and the main workbench 10 is installed with the cleaning chamber 20. In and out track 30, the in and out material trolley 24 is installed on the in and out track 30, the in and out track 30 is connected with the in and out cylinder 70, the upper spray pipe 25 of the large-size bearing is installed at the top position in the cleaning room 20, the cleaning room 20 There is a lower spray pipe 26 at the bottom position of the bottom, and the lower spray pipe 26 is arranged under the feeding and discharging trolley 24, and the upper spraying pipe 25 and the lower spraying pipe 26 are connected with the spray pump 50; The inner fixing fixture 27 and the outer fixing fixture 28 and the upper transmission support frame 29 that are installed with adjustable clamping...

Embodiment 2

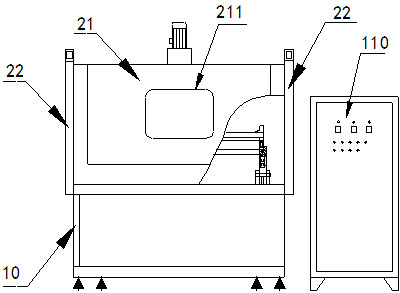

[0027] Lifting motor 22 is installed on cleaning chamber 20 tops (see Figure 4 , Figure 5 ), the internal fixing fixture 27 and the external fixing fixture 28 adopt a manual fixing and adjusting clamping structure. Adjust the inner fixing fixture 27 and the outer fixing fixture 28 to clamp and fix the inner and outer rings of the large-size bearing on the upper transmission support frame 29 . All the other are identical with embodiment 1.

Embodiment 3

[0029] Inner fixing fixture 27 and outer fixing fixture 28 and upper transmission support frame 29 adopt the material structure of iron metal material structure outer cover oil resistance, anti-bearing bump, as plastic material structure. All the other are identical with embodiment 1.

[0030] When preparing to clean, enter and exit the cylinder to drive the inner and outer fixing fixtures of the inner and outer bearings and the uploading support frame 29 to the position of the loading and unloading table 40, hang the large-size bearing on the uploading support frame 29 by a crane, and start the motor to adjust the internal The positions of the fixing fixture 27 and the outer fixing fixture 28 are such that the inner ring of the large-size bearing is fixed by the inner fixing fixture 27, the outer ring is fixed by the outer supporting fixture 28, and the entire inner and outer fixing fixtures and the uploading support frame 29 are fixed on the feeding and discharging trolley A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com