Automatic multi-electricity-meter-position parameter setting and detecting method

A detection method and multi-epitope technology, which can be used in measuring devices, measuring electrical variables, instruments, etc., can solve the problems of high labor intensity, high production cost, low production efficiency, etc., and achieve reliable design principles, high degree of automation, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The specific process steps for the automatic setting and detection of multi-epitope parameters involved in this embodiment include:

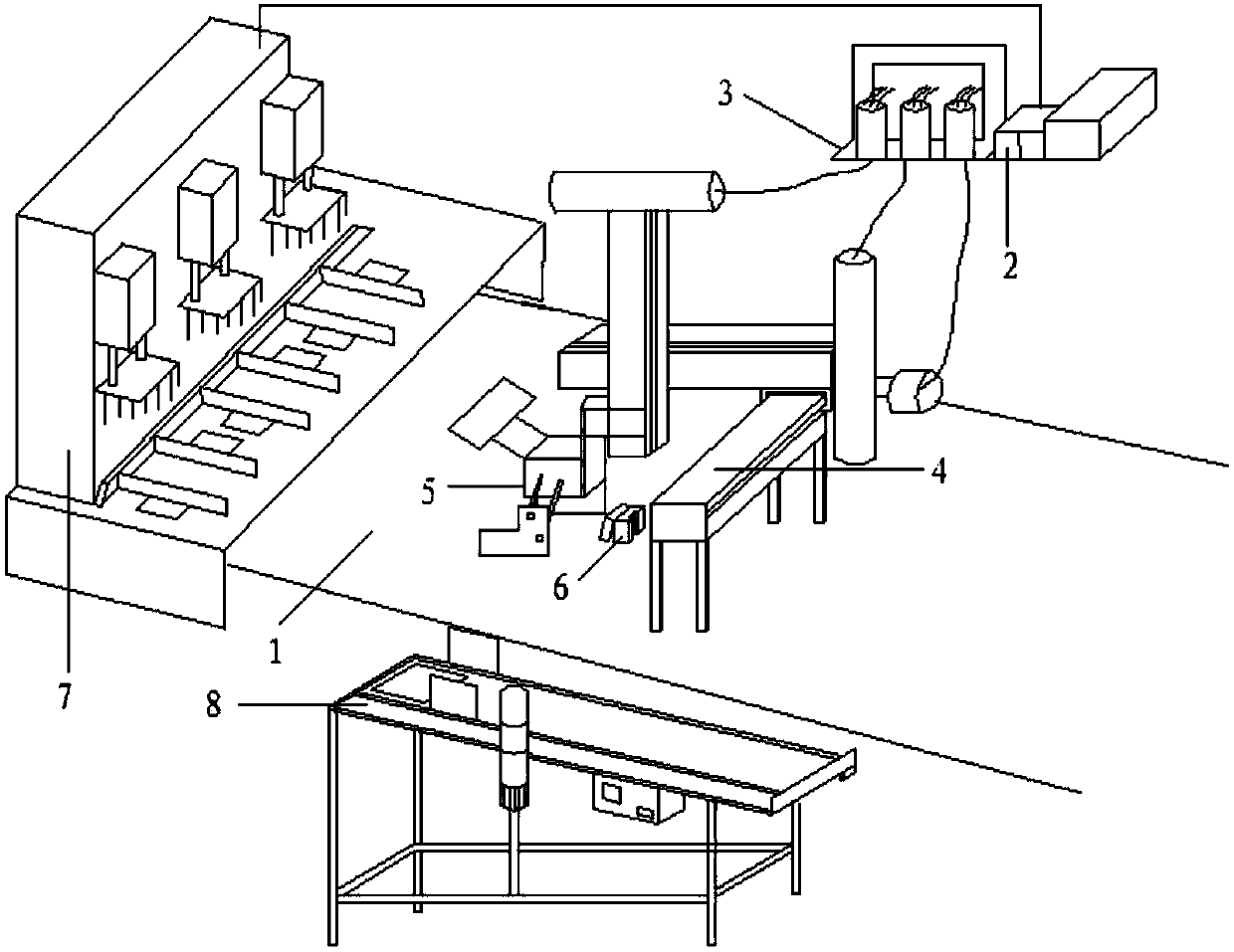

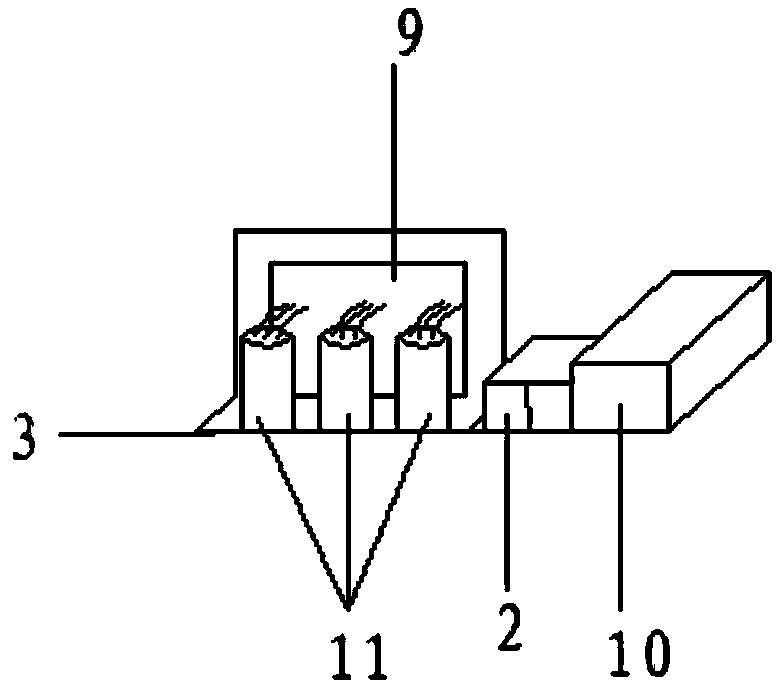

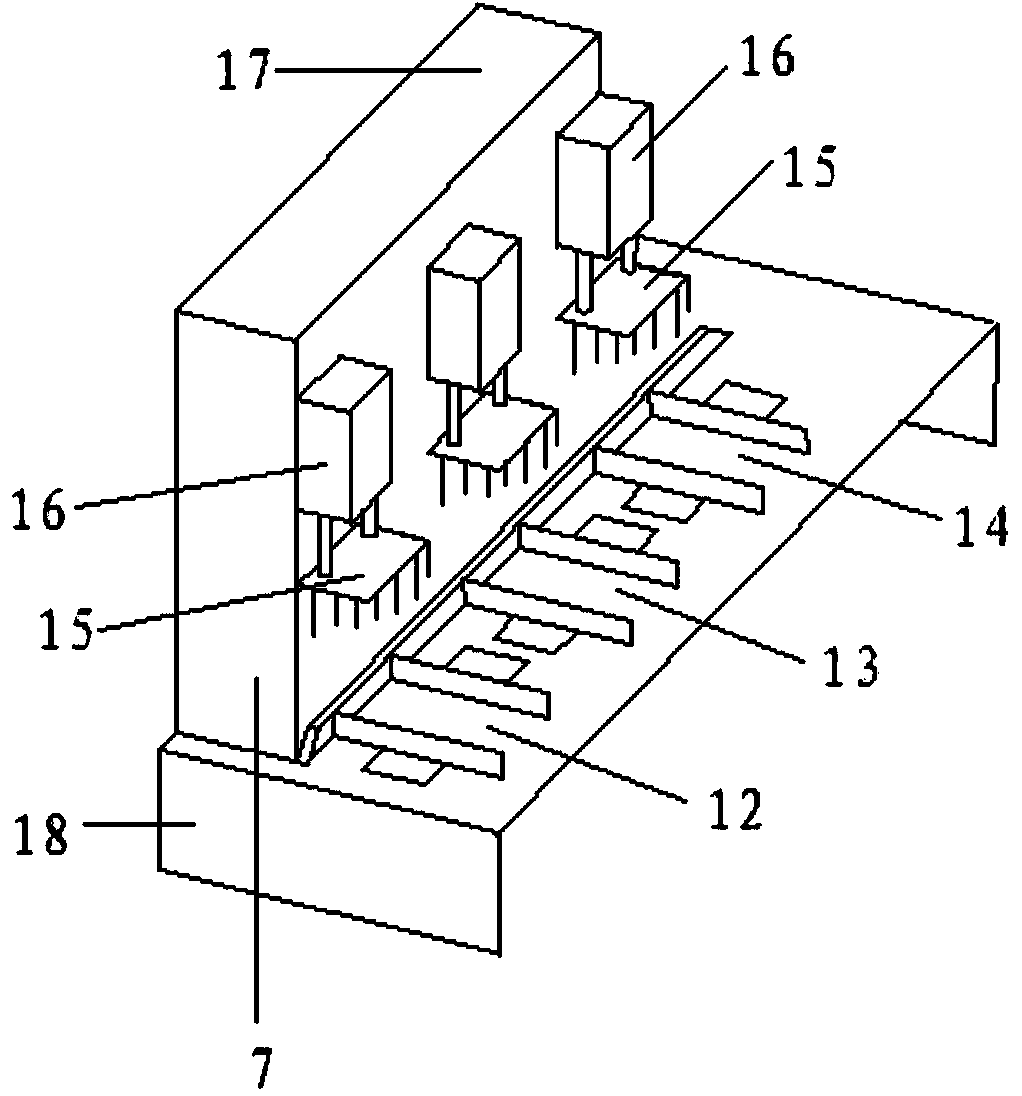

[0019] (1) First, the meter production line 1, the host control unit 2, the robotic arm controller 3, the robotic arm 4, the robotic arm gripper 5, the in-position recognizer 6, the multi-meter testing equipment 7, and the defective product recovery device 8, according to Conduct electrical and physical connections based on logical principles and structural relationships, then configure the serial port of the host control unit 2, and configure the communication address, initialization, meter reset, date / time, identity authentication, remote switching, product code and software of the meter The version number and other parameters are preset;

[0020] (2) When the electric meters on the electric meter production line 1 flow to the in-position recognizer 6 according to the automatic production sequence, the in-place recognizer 6 intercepts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com