Car lithium battery voltage inner resistance automatic detection sorting device

An automatic detection, lithium battery technology, applied in sorting and other directions, can solve problems such as low efficiency, achieve high efficiency, save labor and labor costs, test accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

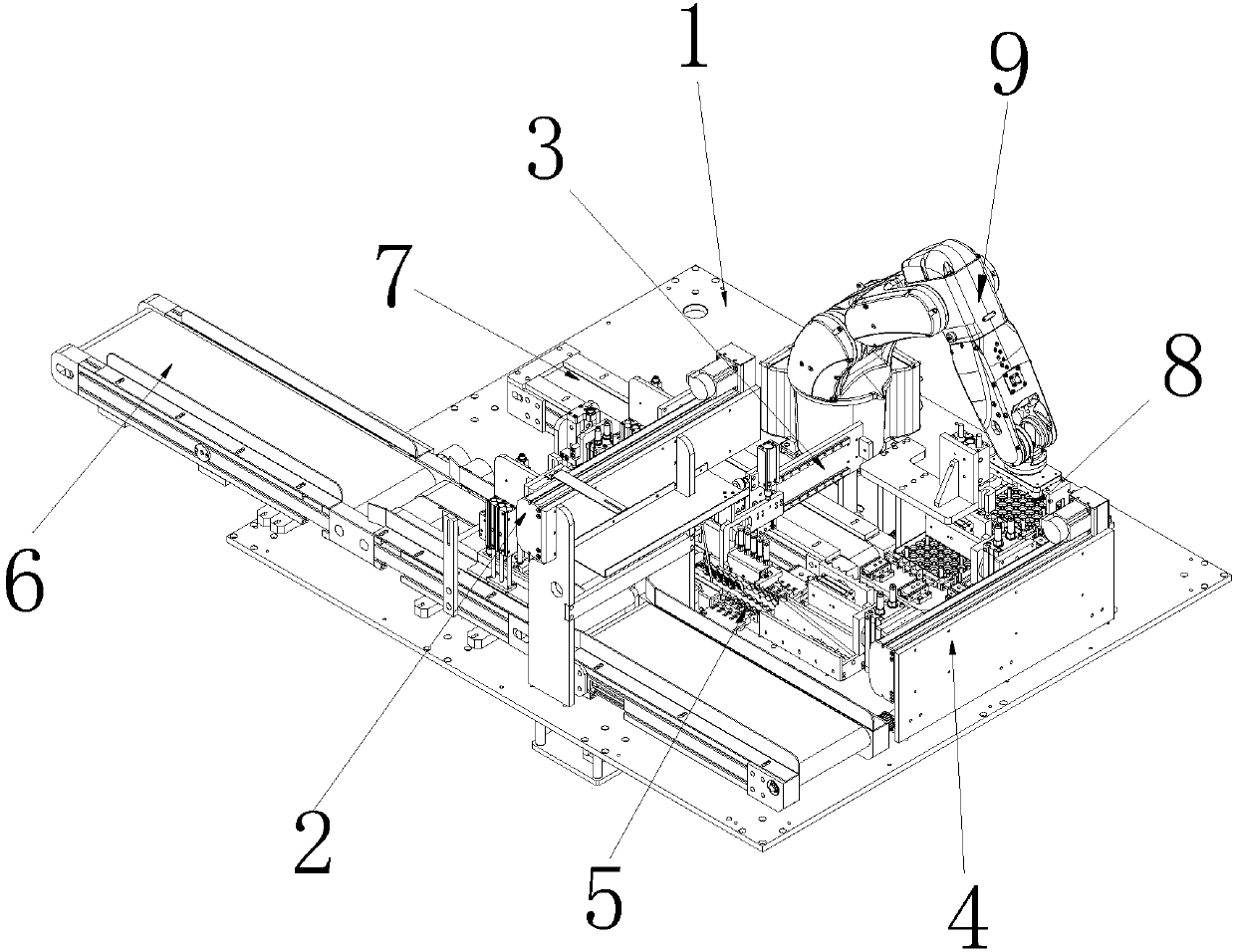

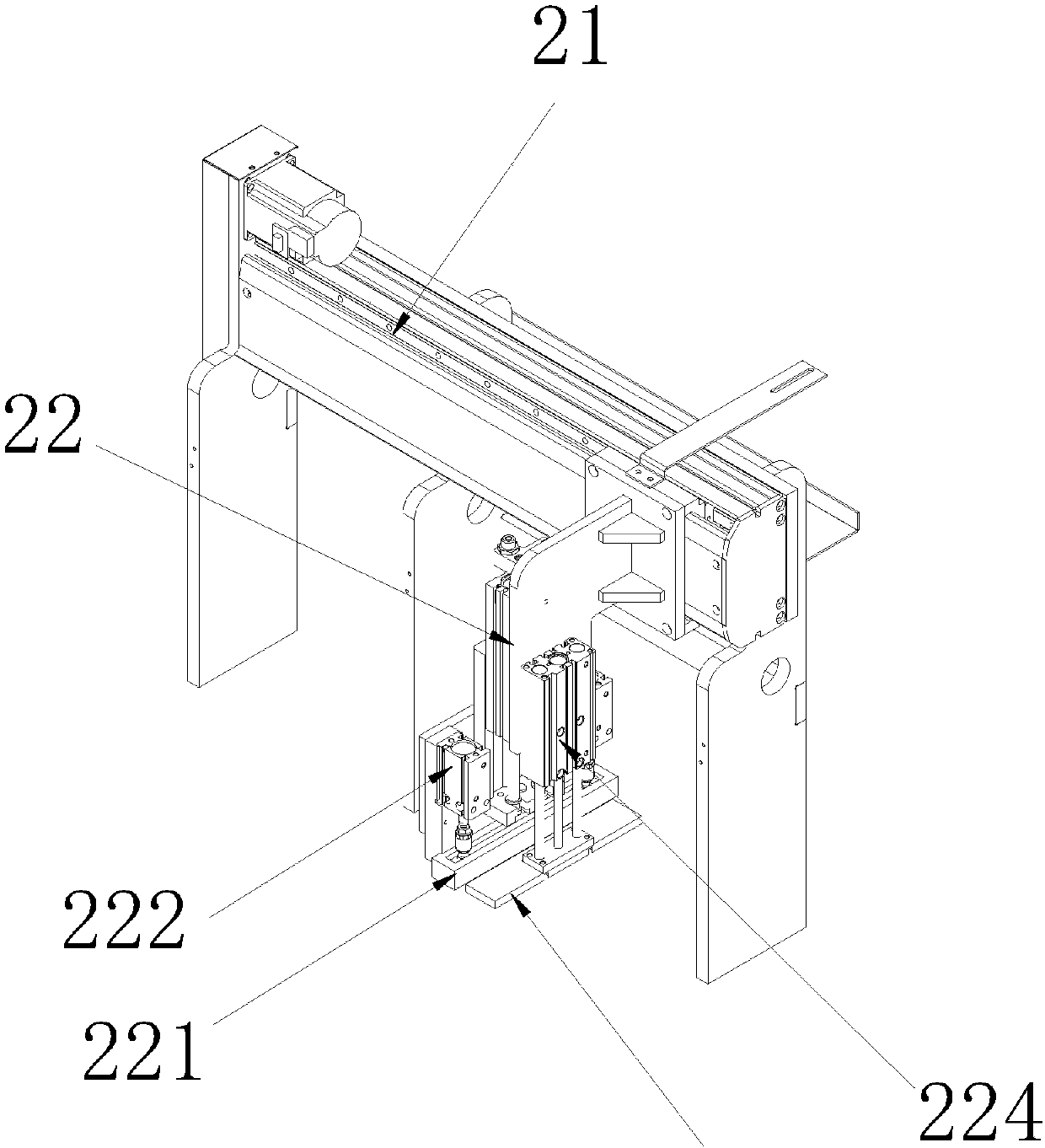

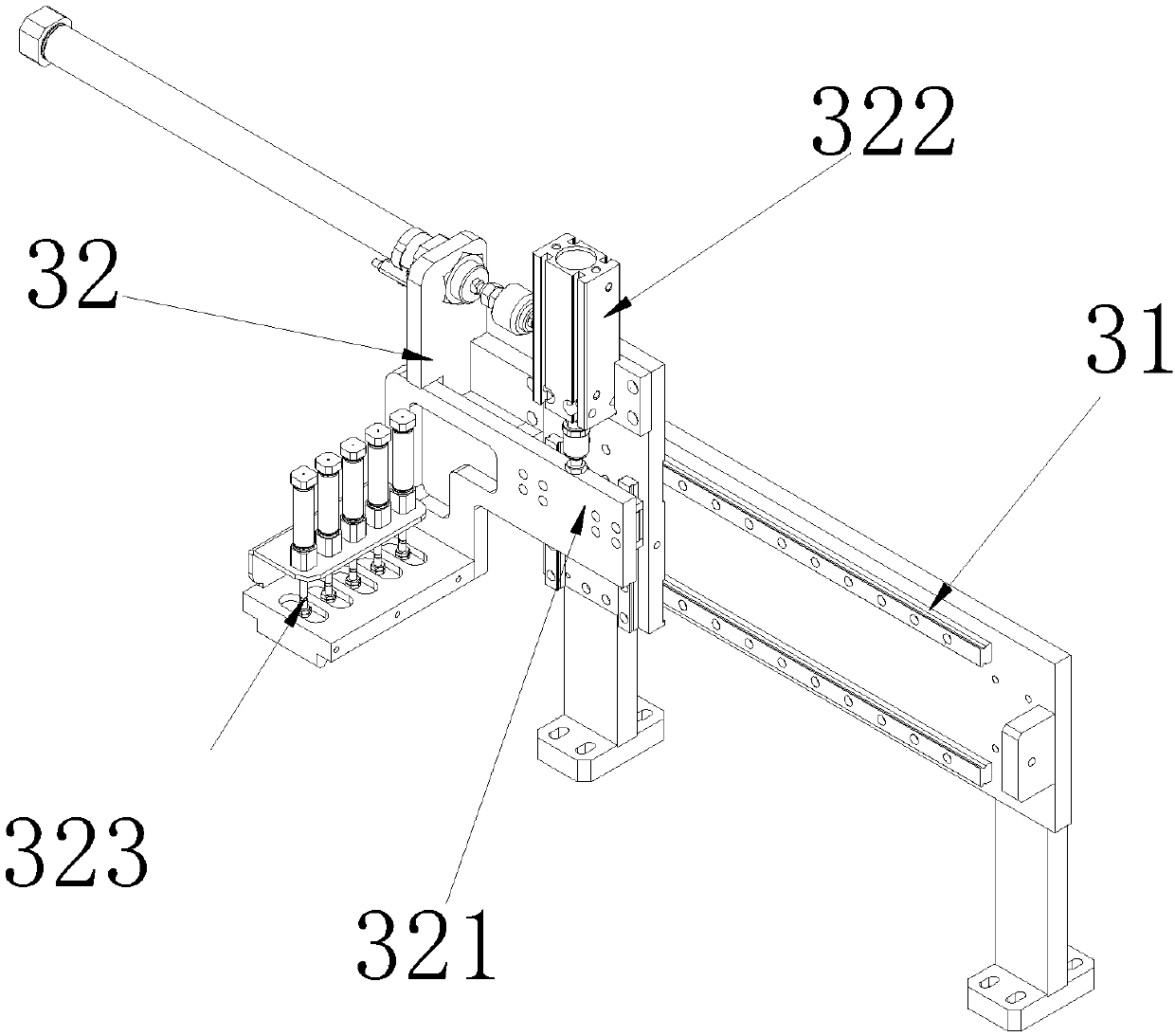

[0025] see Figure 1-5 As shown, the present invention relates to an automatic detection and sorting device for the voltage internal resistance of a lithium battery for automobiles, including a base 1, a feed line 6, a code scanning detection mechanism 5, a battery manipulator, a manipulator for retrieving defective products 3, and a production line for recovering defective products 7. Good product boxing manipulator 4 and charging box 8, the feed line 6, code scanning detection mechanism 5, and defective product recovery line 7 are fixed side by side on the base 1 in sequence, and the charging box 8 is adjacently arranged on the scanning On one side of the discharge place of the code detection mechanism 5, the battery fetching manipulator 2 straddles the feeding line 6 and the code scanning detection mechanism 5 feeding place, and the defective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com