System, device and method for preparing active carbon

A technology for preparing activated carbon and activated carbon, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of insufficient utilization of gas products and a large amount of heat energy resources, low recovery rate of solid carbon, waste of resources, etc. Achieve the effects of full energy utilization, high recovery rate and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

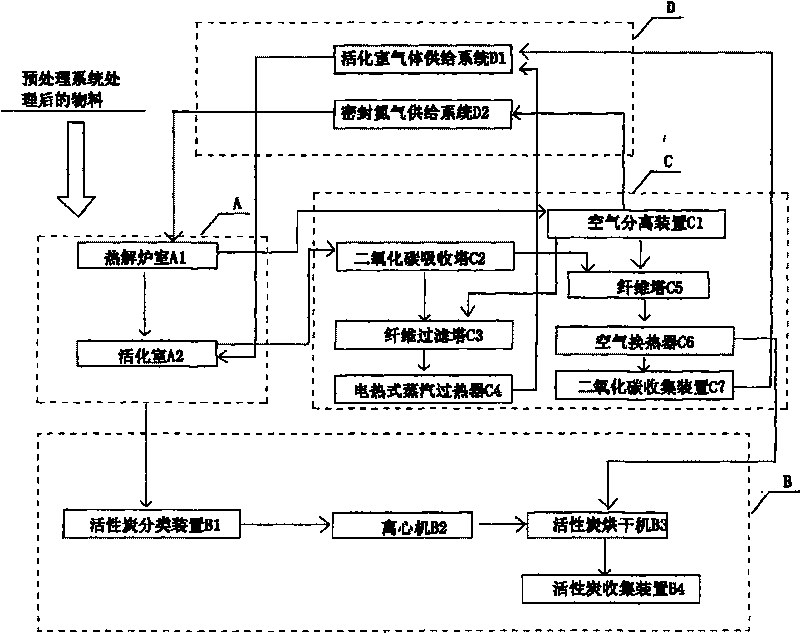

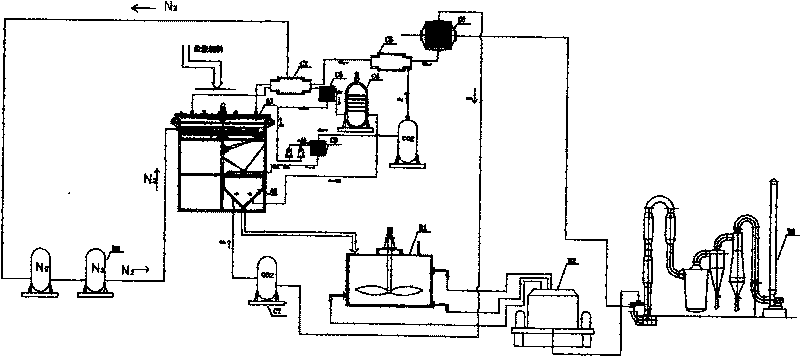

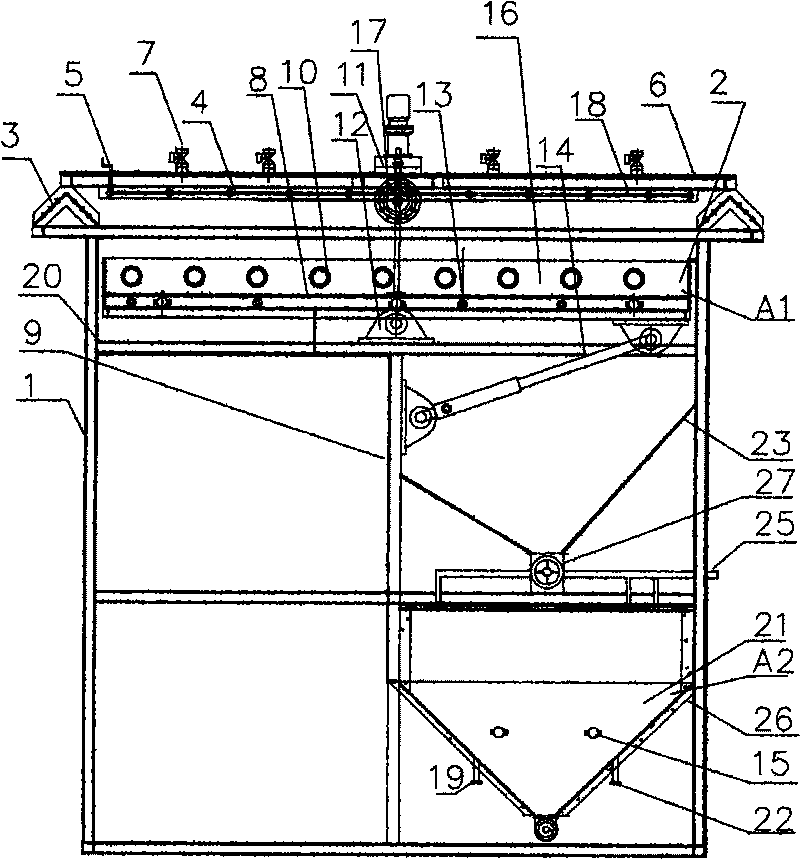

[0016] The invention adopts a microwave heating physical activation method to prepare activated carbon. See attached figure 1 , the technical scheme adopted in the present invention is:

[0017] A production system for preparing activated carbon, the system includes: pyrolysis treatment subsystem A for pyrolysis treatment of pretreated materials, activated carbon finishing system B for further sorting and dehydration treatment of primary carbonized products, the system adopts A microwave heating type, closed low-temperature pyrolysis, carbonization, and activation integrated furnace is used as the main equipment of the pyrolysis treatment subsystem A. The material is cracked in the pyrolysis furnace chamber A1, and the carbonized residue after cracking enters the activation chamber A2 for processing into primary Activated carbon products are then transferred to activated carbon finishing sub-system B, which is set up for pyrolysis treatment sub-system A, including carbonizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com