Method for recycling transparent conducting glass substrate of solar cell

A transparent conductive glass, solar cell technology, applied in recycling technology, electronic waste recycling, circuits, etc., can solve the problems of process failure, cost increase, defective products, etc., and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Please refer to 5, Figure 6A , Figure 6B and Figure 6C , the present invention is a method for recycling a transparent conductive glass substrate of a solar cell, which comprises the following steps:

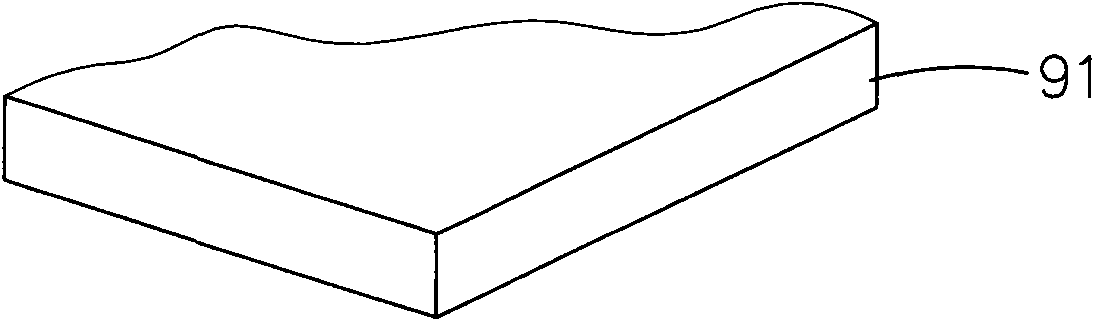

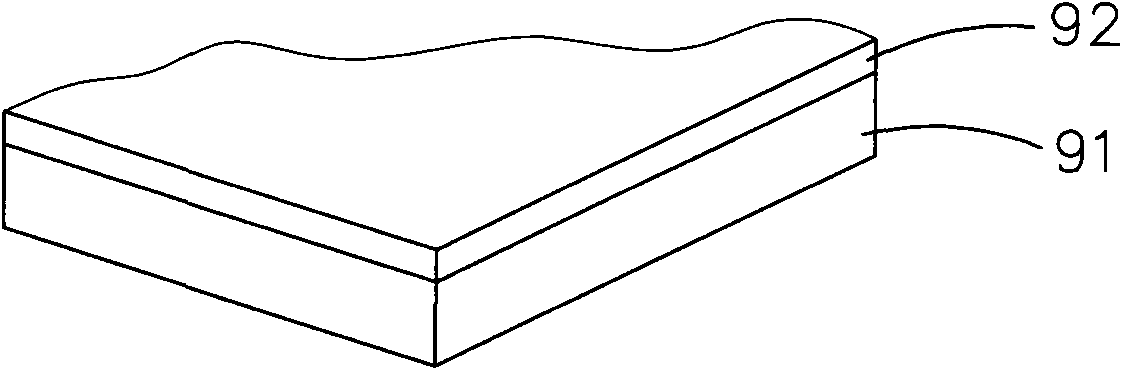

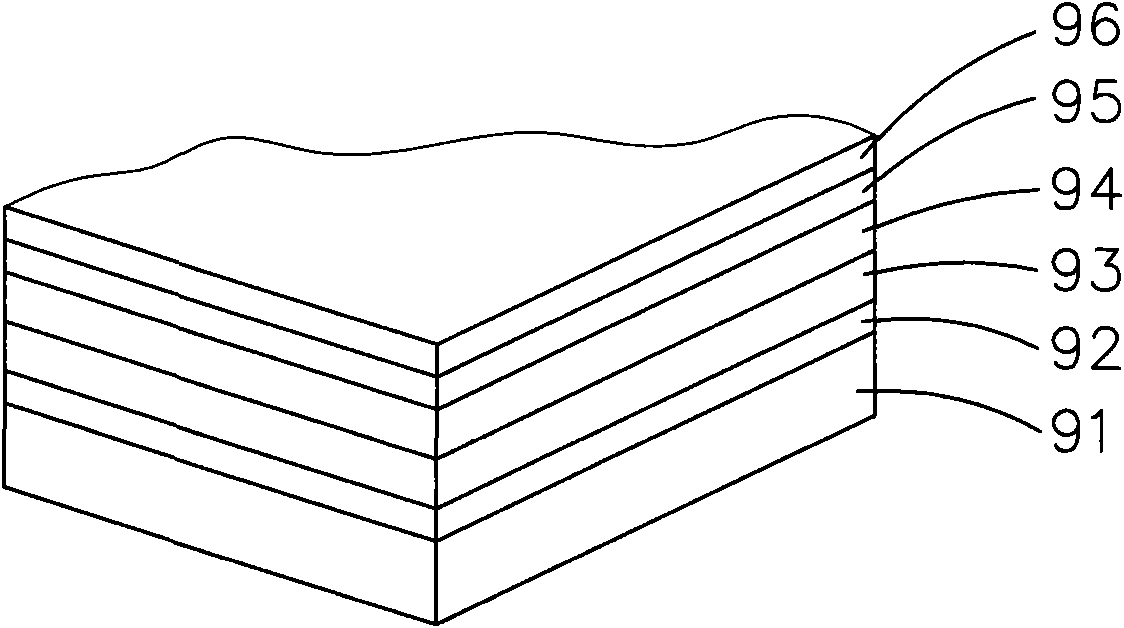

[0037] 1. Preparation step 11: Prepare a defective solar cell with a process failure, which has a glass substrate 21, a transparent conductive glass layer 22 and a process failure layer 23 in sequence; the process failure layer 23 is selected from single crystal silicon, polycrystalline silicon , one of microcrystalline silicon and amorphous silicon; in fact, it may include one of p-Si layer, i-Si layer and n-Si layer (monocrystalline silicon or polycrystalline silicon solar cells generally have p-Si layer and i-Si layer, and thin solar cells generally have p-Si layer, i-Si layer and n-Si layer), but its composition is mainly silicon (Si);

[0038] 2. Etching step 12: Selectively etch the defective solar cell with an etching medium 30, the etching rate of the etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com